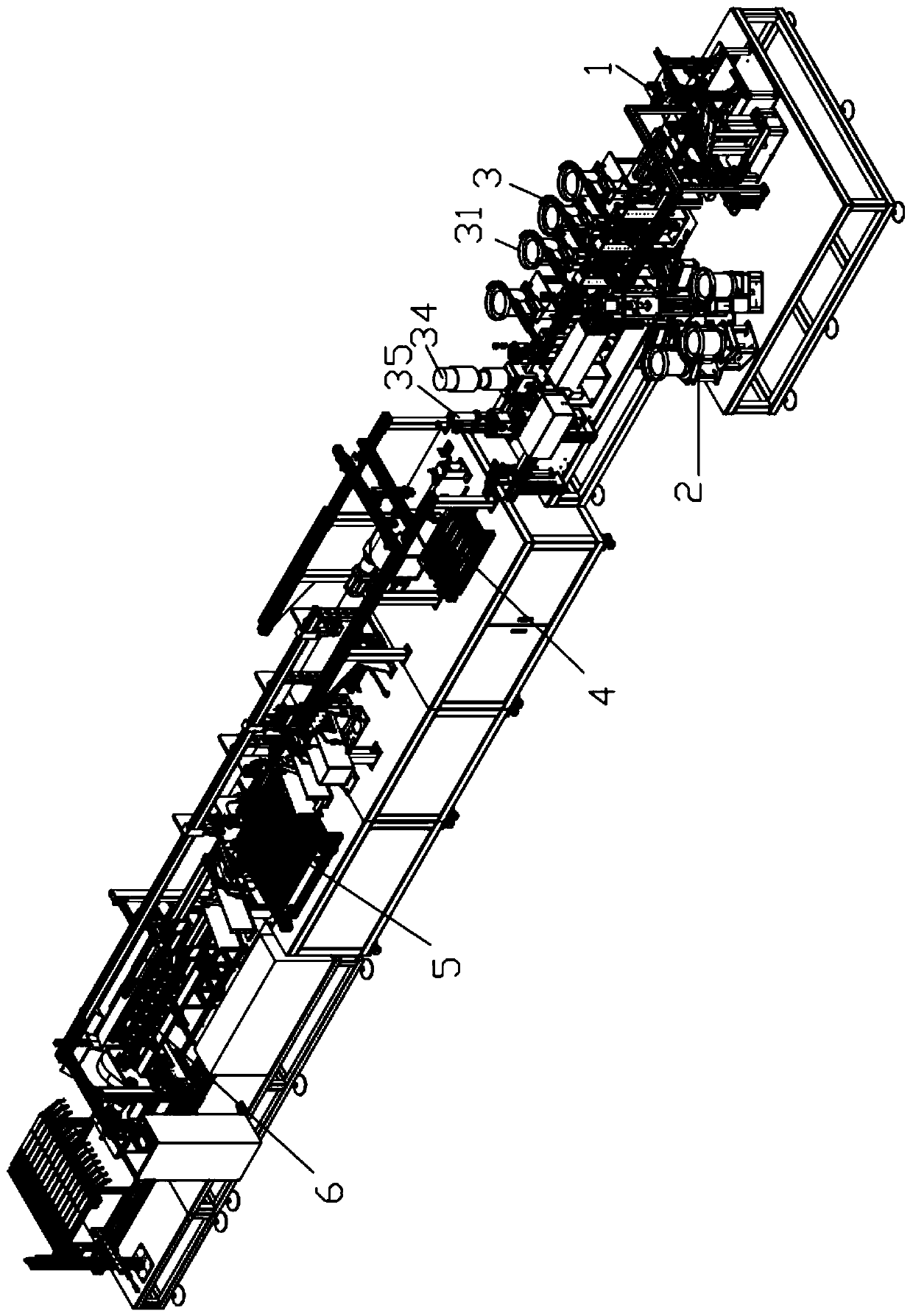

Production line of back door stay assy

A production line and tailgate technology, applied to assembly machines, metal processing equipment, manufacturing tools, etc., can solve problems such as unfavorable industrial production, large assembly errors, and low work efficiency, so as to improve production efficiency, product quality rate, and reasonable layout Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

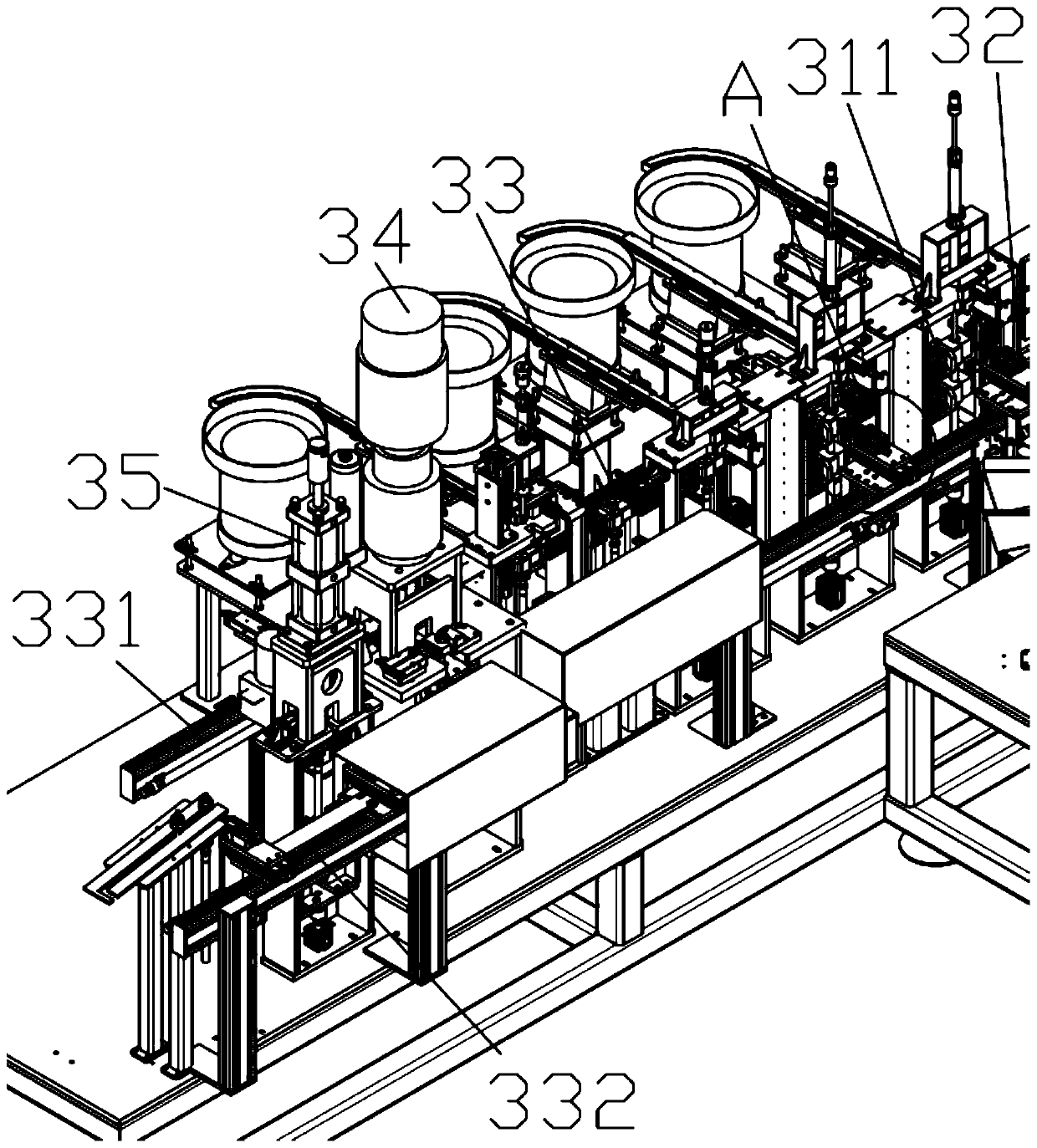

Method used

Image

Examples

Embodiment approach

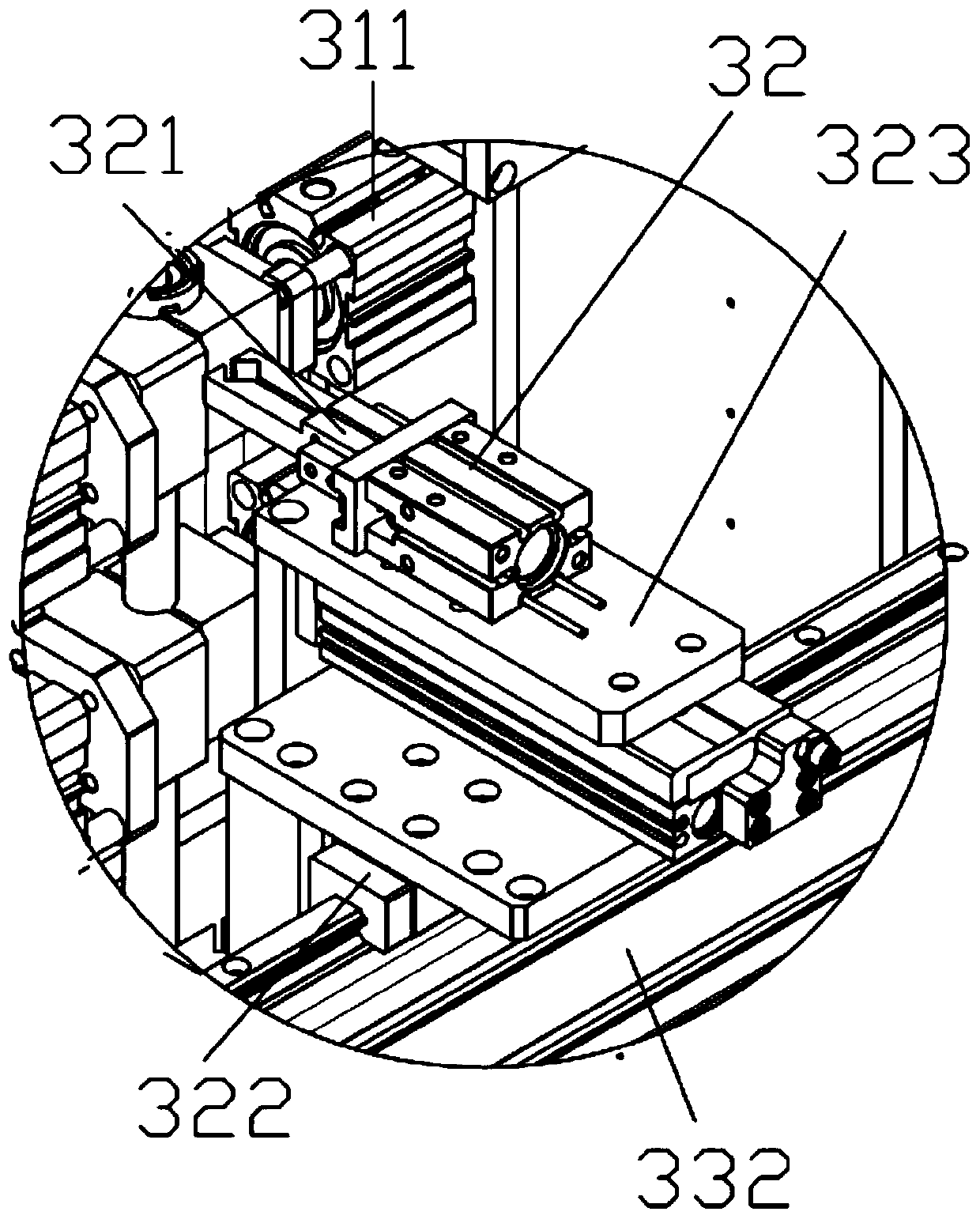

[0043] As an embodiment of the present invention, in this embodiment, the first translation drive assembly includes a translation cylinder 1-24, and the end of the piston rod of the translation cylinder 1-24 is connected with the first sliding seat 1-22, through which the translation cylinder The expansion and contraction of the piston rod of 1-24 controls the first clamping mechanism 1-3 to approach or move away from the first clamping mechanism 1-3, and the first clamping mechanism can be adjusted by adjusting the installation position of the translation cylinder 1-24 or the telescopic degree of the piston rod The distance between the clamping mechanism 1-3 and the first clamping mechanism 1-3 can be adjusted to adjust the length of the threaded rod 71 protruding from the inner conduit 72 after assembly, so as to meet different product specification requirements.

[0044] In this embodiment, the second translation drive assembly includes a translation motor 1-25 and a screw r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com