Mold opening and closing mechanism

A technology of mold opening and closing and driving mechanism, which is applied in the direction of molds, ceramic molding machines, mold separation devices, etc., can solve the problems of asynchronous displacement at both ends, low production efficiency, heavy time cost, etc., and achieve high product quality and increase Production efficiency and the effect of improving the level of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

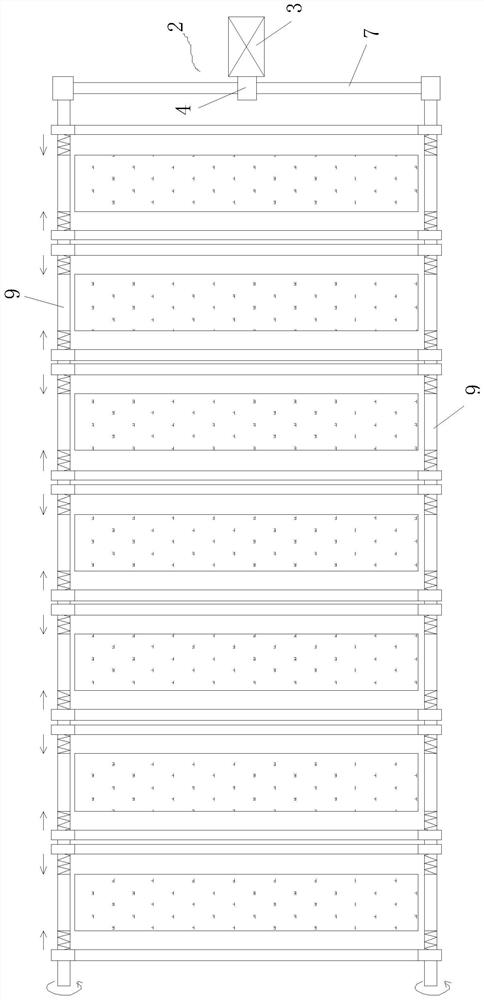

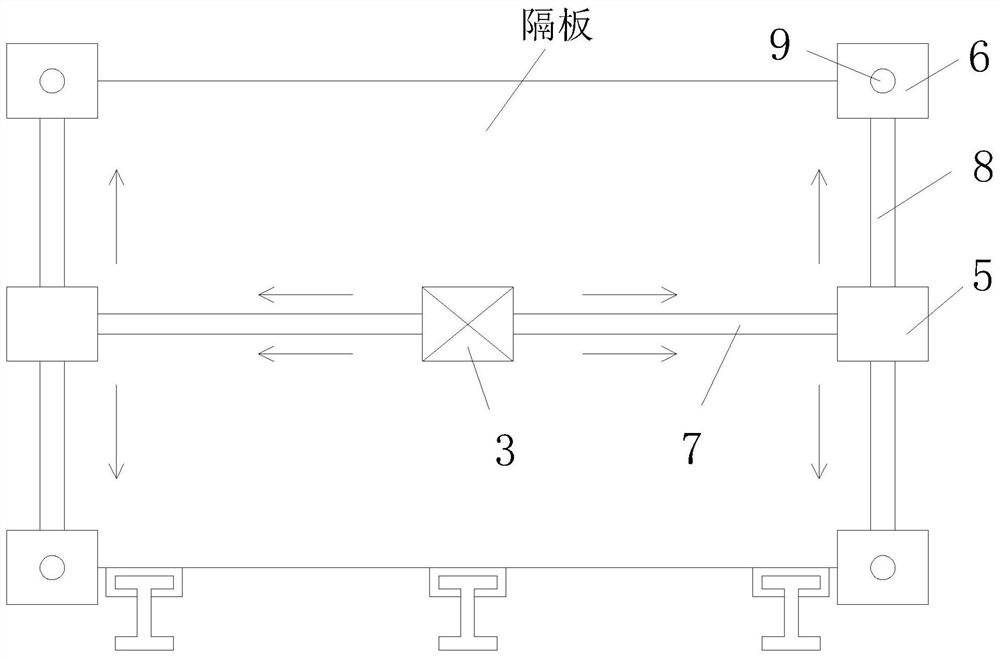

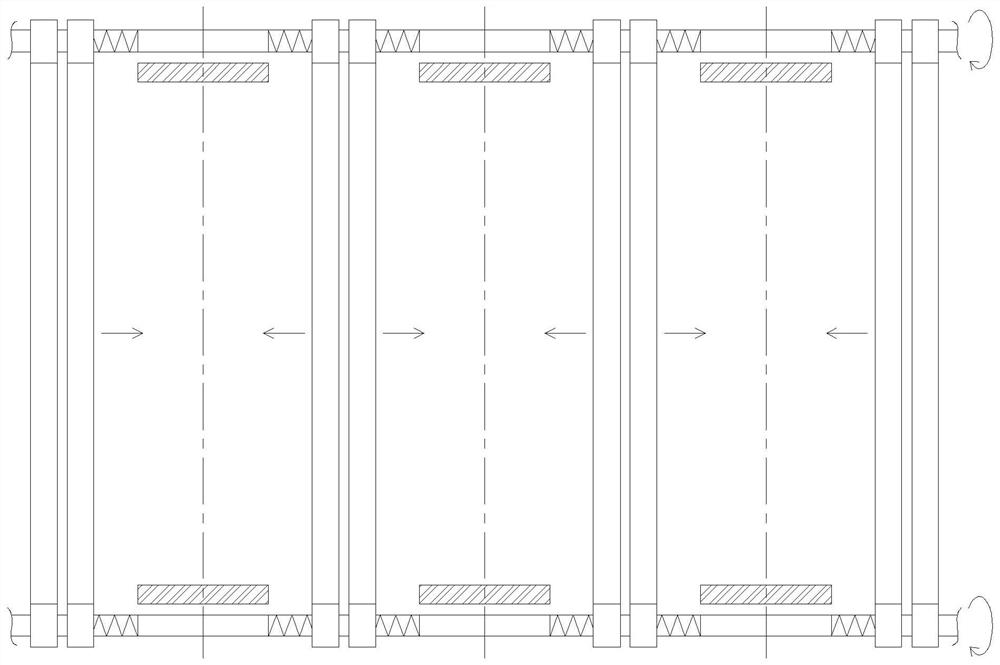

[0034] Such as Figure 1 to Figure 7 As shown, this embodiment discloses a mold opening and closing mechanism, which mainly includes a combined mold 1 and a driving mechanism 2 for driving the combined mold 1 to open or close the mold. The combined mold 1 is composed of a top plate, a bottom plate, a side plate, and two partition plates. Several combined molds 1 are arranged side by side on the guide rail. The driving end of the driving mechanism 2 is respectively connected to the partitions of each group of combined molds 1, and drives the two partitions to move towards or back at the same time, so as to realize the closing or opening of the combined mold 1.

[0035] Furthermore, the drive mechanism 2 provided by the present invention can adopt a rotary drive type or a direct drive type. When the rotary drive type is used, the drive mechanism 2 drives the partition to move toward or back through forward rotation or reverse rotation, mainly It includes a motor 3 , a first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com