Testing device for bridge plug setting test

A technology for test testing and monitoring devices, which is applied to measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of unstable product quality, inability to meet well depth, high bottom hole pressure, etc., and achieve intuitive and intuitive test results. It is easy to promote the application and improve the effect of the excellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in detail below with reference to the accompanying drawings.

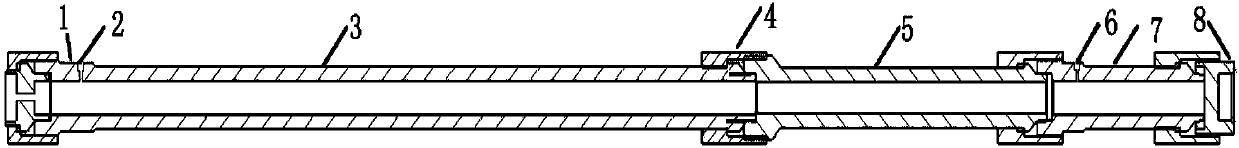

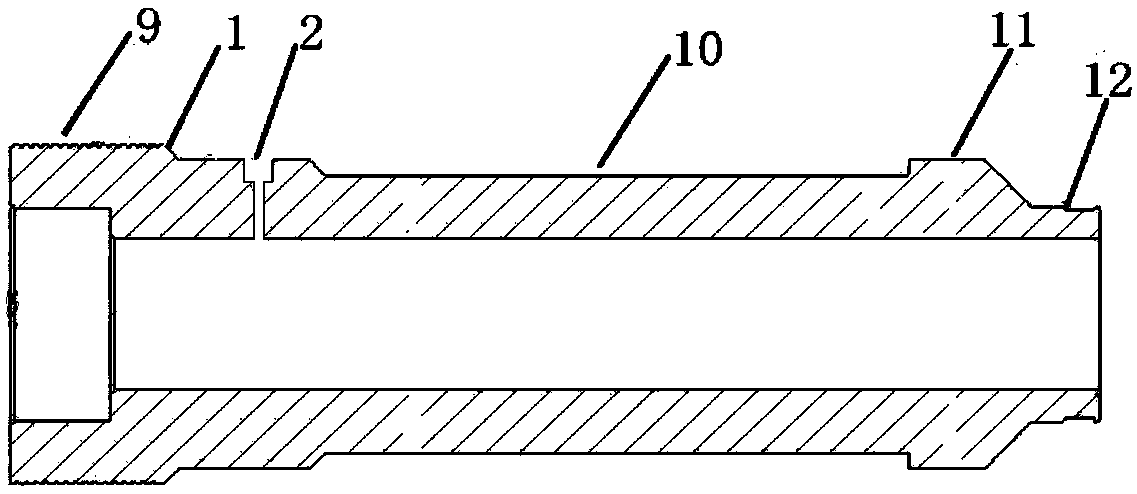

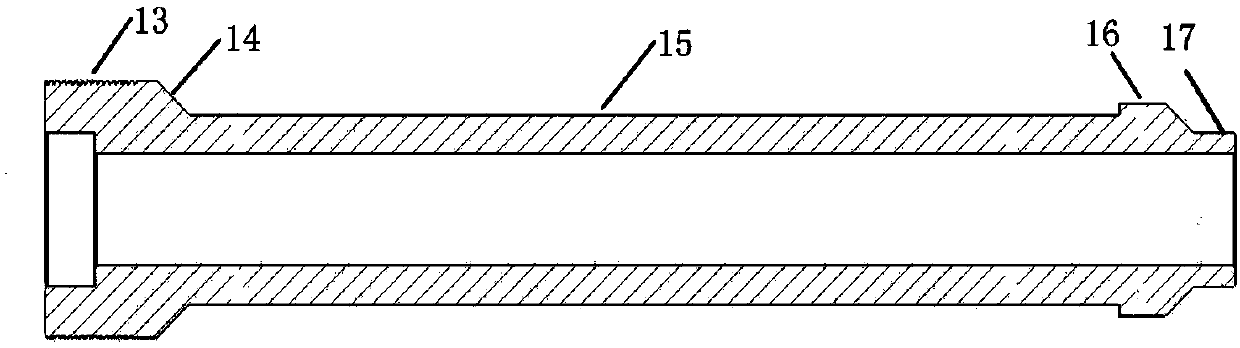

[0018] refer to figure 1 , the mechanical pressure test unit 3 of the present invention has a joint 1 on the upper end, and the side of the mechanical pressure test unit has a plugging port 1, a pressure transmitter interface 1 and three pressure ports 2 on the pressure port, and the pressurization ports are sequentially arranged. Connect the pneumatic pressure pump and air pump; the right end of the mechanical pressure test unit is connected to the bridge plug pressure test unit 5 through the union joint 4, and the bridge plug pressure test unit is connected to the electronic pressure test monitoring device 7 through the union joint. The pressure test monitoring device is connected to the joint 8 through the union joint, and the side of the electronic pressure test monitoring device has a second plugging port, a second pressure transmitter interface and three lower pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com