Conductive fiber with scabbard type structure and preparation method thereof

A conductive fiber and scabbard technology, which is applied in the field of fiber and its preparation, can solve the problems affecting the conductivity of the fiber, and achieve the effect of excellent flexibility, high strength, and easy purchase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

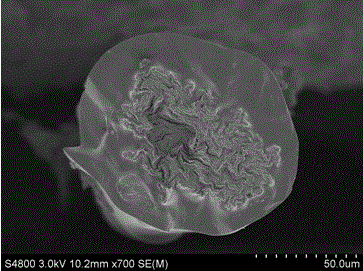

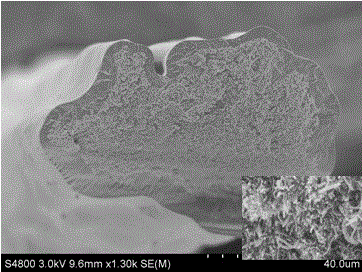

Image

Examples

preparation example Construction

[0026] The preparation method of the conductive fiber of scabbard structure comprises the following steps:

[0027] 1) Dissolving 1 part by weight of carbon nanomaterials in 20 to 200 parts by weight of solvent to prepare solution 1;

[0028] 2) Dissolving 1 part by weight of polymer in 20-200 parts by weight of solvent to form solution 2;

[0029] 3) Pass solution 1 through the inner tube of the coaxial spinning needle at a speed of 5-500 μL / min, and at the same time, extrude solution 2 through the outer tube of the coaxial spinning needle at a speed of 5-500 μL / min to Stay in the coagulation bath for 1min to 2h to form gel fibers with a scabbard structure;

[0030] 4) Chemically reducing 1 part by weight of the gel fiber with 1 to 200 parts by weight of a reducing agent at 60 to 120°C for 1 min to 24 hours;

[0031] 5) The gel fibers reduced in step 4) are washed with a solvent, dried at 25-100° C., and then collected on a roller to obtain conductive fibers with a scabbard...

Embodiment 1

[0037] 1) Dissolve 200 mg of graphene oxide in 40 mL of water to make a 5 mg / mL graphene oxide aqueous solution;

[0038] 2) Dissolve 200 mg of sodium carboxymethyl cellulose in 40 mL of water to make a 5 mg / mL sodium carboxymethyl cellulose solution;

[0039] 3) Pass the graphene oxide aqueous solution through the inner tube of the coaxial spinning needle at a speed of 5 μL / min, and at the same time, pass the sodium carboxymethyl cellulose solution through the outer tube of the coaxial spinning needle at a speed of 5 μL / min Extrude into a 5% calcium chloride coagulation bath for 30 minutes to initially form a gel fiber with a scabbard structure;

[0040] 4) Chemically reduce the gel fiber with 1 mL of hydroiodic acid at 95°C for 1 hour;

[0041] 5) The gel fibers reduced in step 4 are washed with a mixed solution of water and ethanol (volume ratio 1:3), dried at 30°C, and then collected on a roller to obtain a conductive scabbard-shaped structure. fiber.

[0042] After the...

Embodiment 2

[0044] 1) Dissolve 200 mg of graphene oxide in 10 mL of water to make a 20 mg / mL graphene oxide aqueous solution;

[0045] 2) Dissolve 200 mg of polyethylene glycol in 40 mL of water to make a 5 mg / mL polyethylene glycol solution;

[0046]3) Pass the graphene oxide aqueous solution through the inner tube of the coaxial spinning needle at a speed of 5 μL / min, and at the same time, squeeze the polyethylene glycol solution through the outer tube of the coaxial spinning needle at a speed of 10 μL / min Stay in the 5% calcium chloride coagulation bath for 10 minutes, and initially form the gel fiber of the scabbard structure;

[0047] 4) Chemically reduce the gel fiber with 1 mL of hydrazine hydrate at 95°C for 1 hour;

[0048] 5) The gel fibers reduced in step 4 are washed with a mixed solution of water and ethanol (volume ratio 1:3), dried at 90°C, and then collected on a roller to obtain a conductive scabbard-shaped structure. fiber.

[0049] After the above steps, the fiber ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com