Method and reactor for pyrolysis conversion of hydrocarbon gases

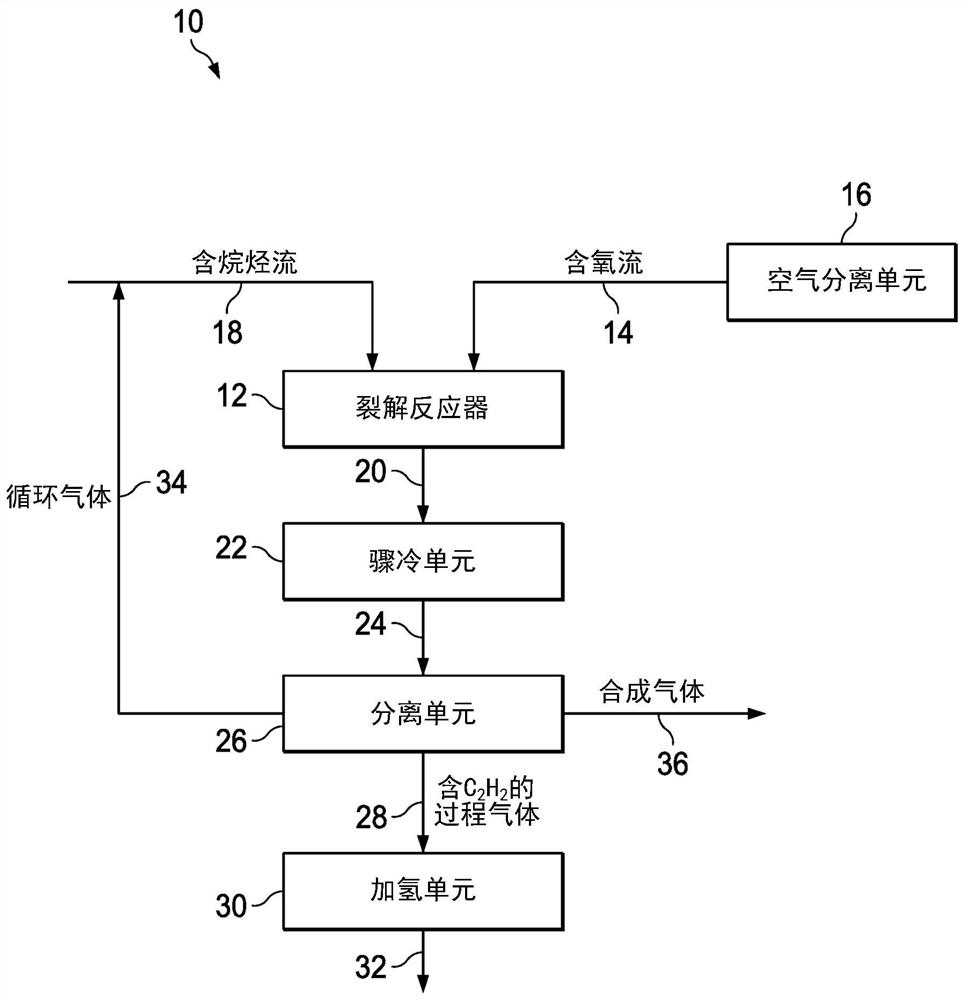

A pyrolysis reactor, the technology of the reactor, is applied in the directions of pyrolysis reaction, gas-gas reaction at high temperature, chemical instruments and methods, etc., and can solve problems such as heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

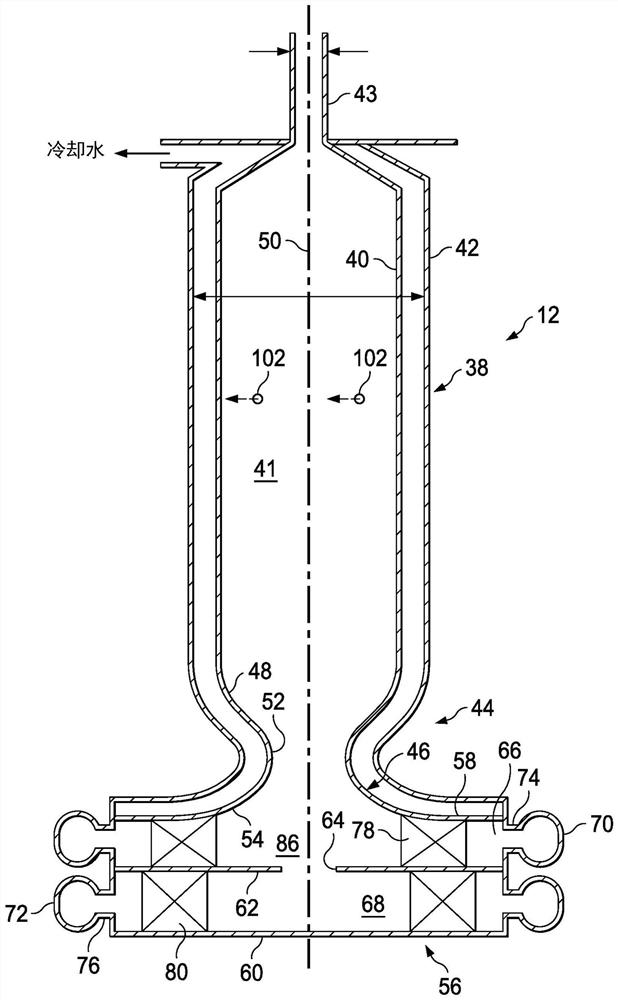

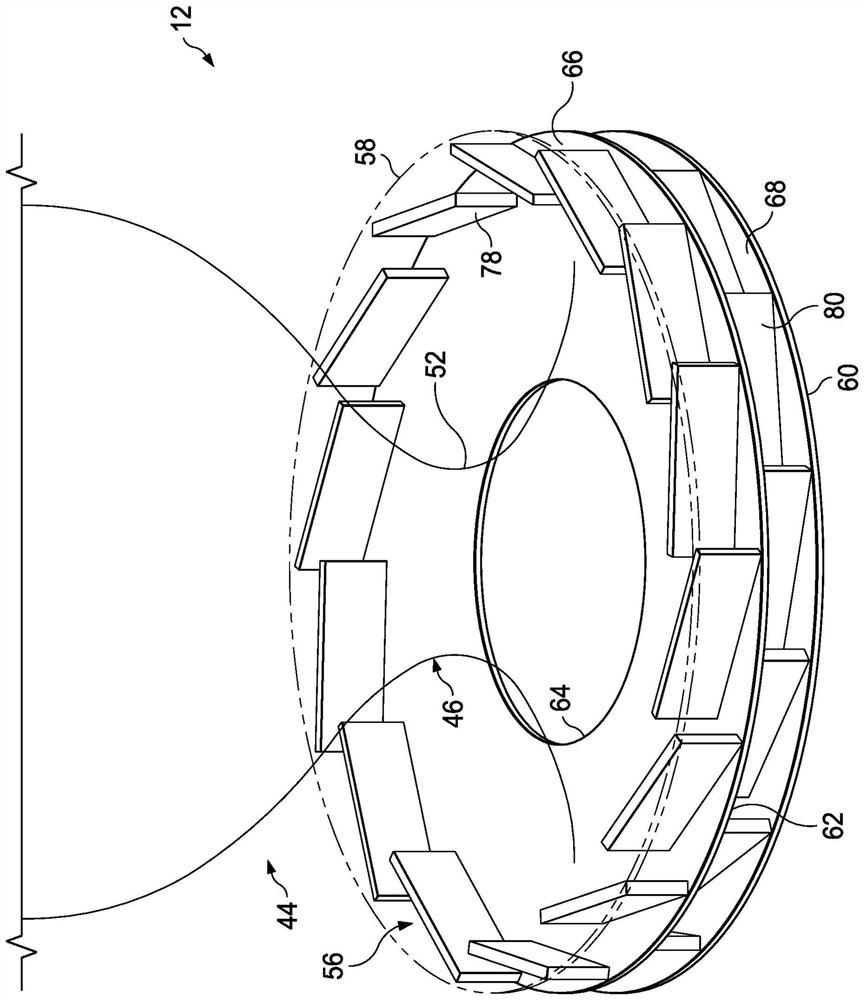

[0091] Image 6 The pyrolysis reactor geometry and axial velocity distribution in a laboratory-scale unit model are shown. The direction of the area arrow indicates the flow direction of the gas phase, and its length indicates the relative magnitude of the velocity. At the inlet of the feed assembly, for O 2 and CH 4 , the axial velocity is zero, the radial velocity is consistent with the azimuth velocity, and the azimuth-radial velocity ratio is 3. This highly swirling flow forms a recirculation zone near the axis of the reactor, as above in Figure 5 As described in , this recirculation zone stabilizes the flame and enhances mixing during combustion. The reflux (close to Image 6 The counterflow area of the axis in the middle) presses the combustion towards the nozzle neck. This can be found at Figure 7 , where the darker areas downstream of the burner duct indicate higher temperatures, while the lighter areas indicate lower temperatures. The backflow of the gas p...

Embodiment 2

[0097] Figure 12 Two inlet streams are shown (CH 4 and O 2 ) combined effect of the azimuth-radial velocity ratio. The co-rotation of the two streams at a high azimuthal-to-radial velocity ratio of 3 achieves peak yields, suggesting that a high azimuthal-to-radial velocity ratio is beneficial for creating a wide recirculation zone and rapid mixing.

Embodiment 3

[0099] Figure 13 The effect of the methane / oxygen molar ratio on pyrolysis performance is shown, the ratio varying from 1.6 to 2.4. Sensitivity analyzes indicated that overall methane conversion decreases with increasing methane / oxygen ratio due to combustion temperature and thermal energy available for pyrolysis. On the other hand, the selectivity increased slightly, from a ratio of 1.6 to a ratio of about 2. As the product of these two indicators, under specific operating conditions, the overall C 2 + Yield peaks at a ratio of about 1.8, reaching about 28.2% at this particular scale. It is worth noting that the optimized methane / oxygen ratio may vary under different reactor sizes, heat losses, and operating pressures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com