Patents

Literature

32 results about "Laser pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In situ modification of group iv nanoparticles using gas phase nanoparticle reactors

A method for creating an organically capped Group IV semiconductor nanoparticle is disclosed. The method includes flowing a Group IV semiconductor precursor gas into a chamber. The method also includes generating a set of Group IV semiconductor precursor radical species from the Group IV semiconductor precursor gas with a laser pyrolysis apparatus, wherein the set of the Group IV semiconductor precursor radical species nucleate to form the Group IV semiconductor nanoparticle; and flowing an organic capping agent precursor gas into the chamber. The method further includes generating a set of organic capping agent radical species from the organic capping agent precursor gas, wherein the set of organic capping agent radical species reacts with a surface of the Group IV semiconductor nanoparticle and forms the organically capped Group IV semiconductor nanoparticle.

Owner:LI XUEGENG +3

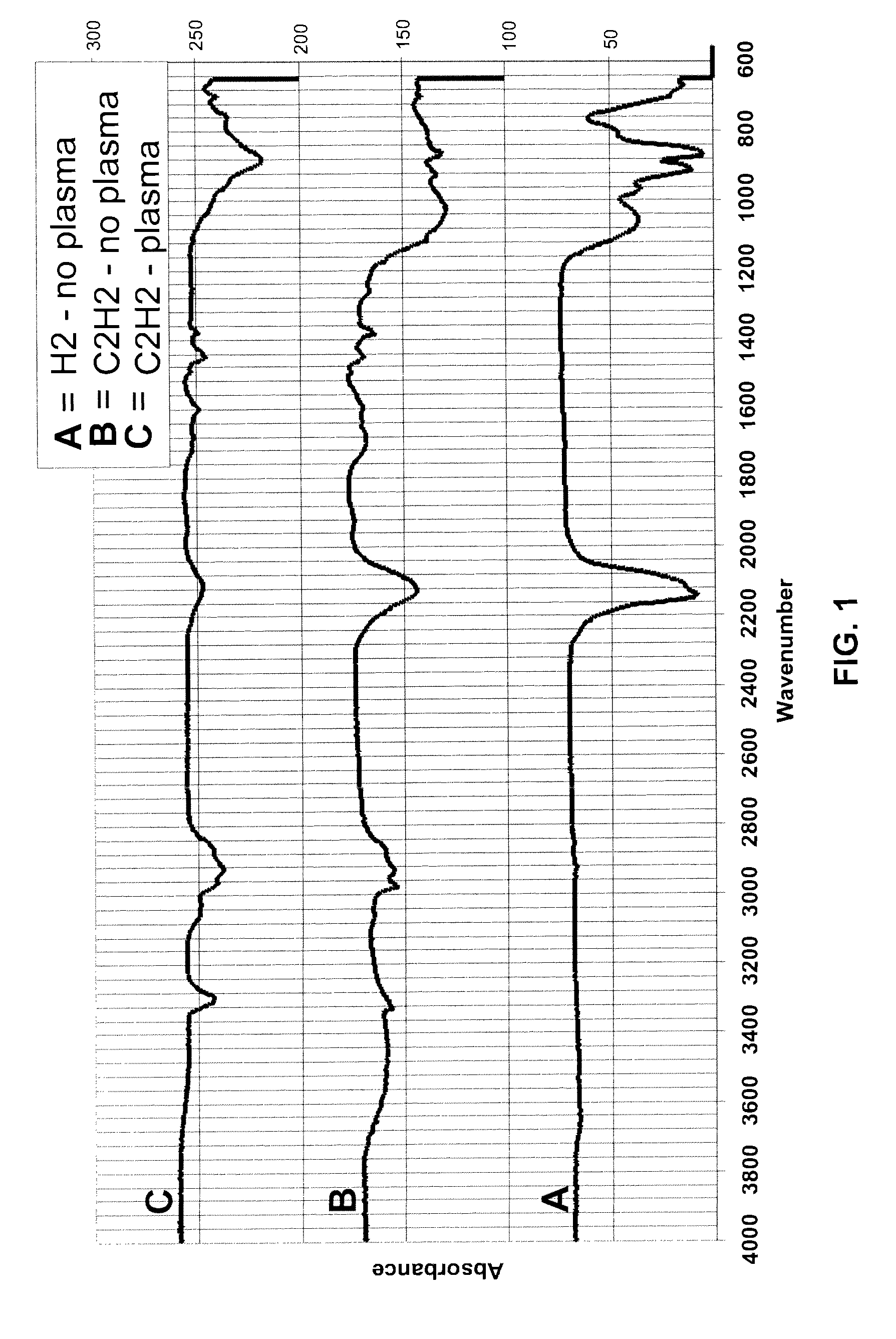

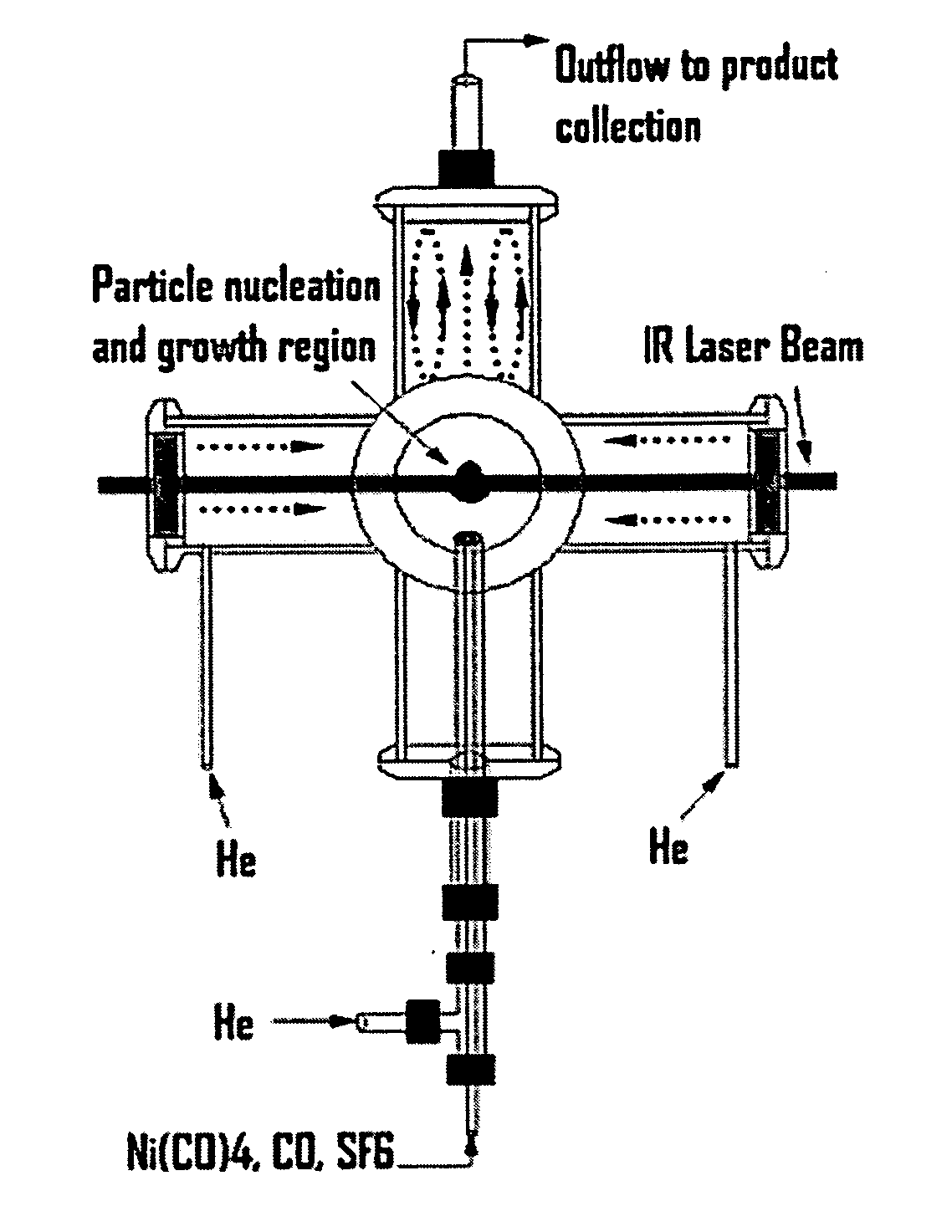

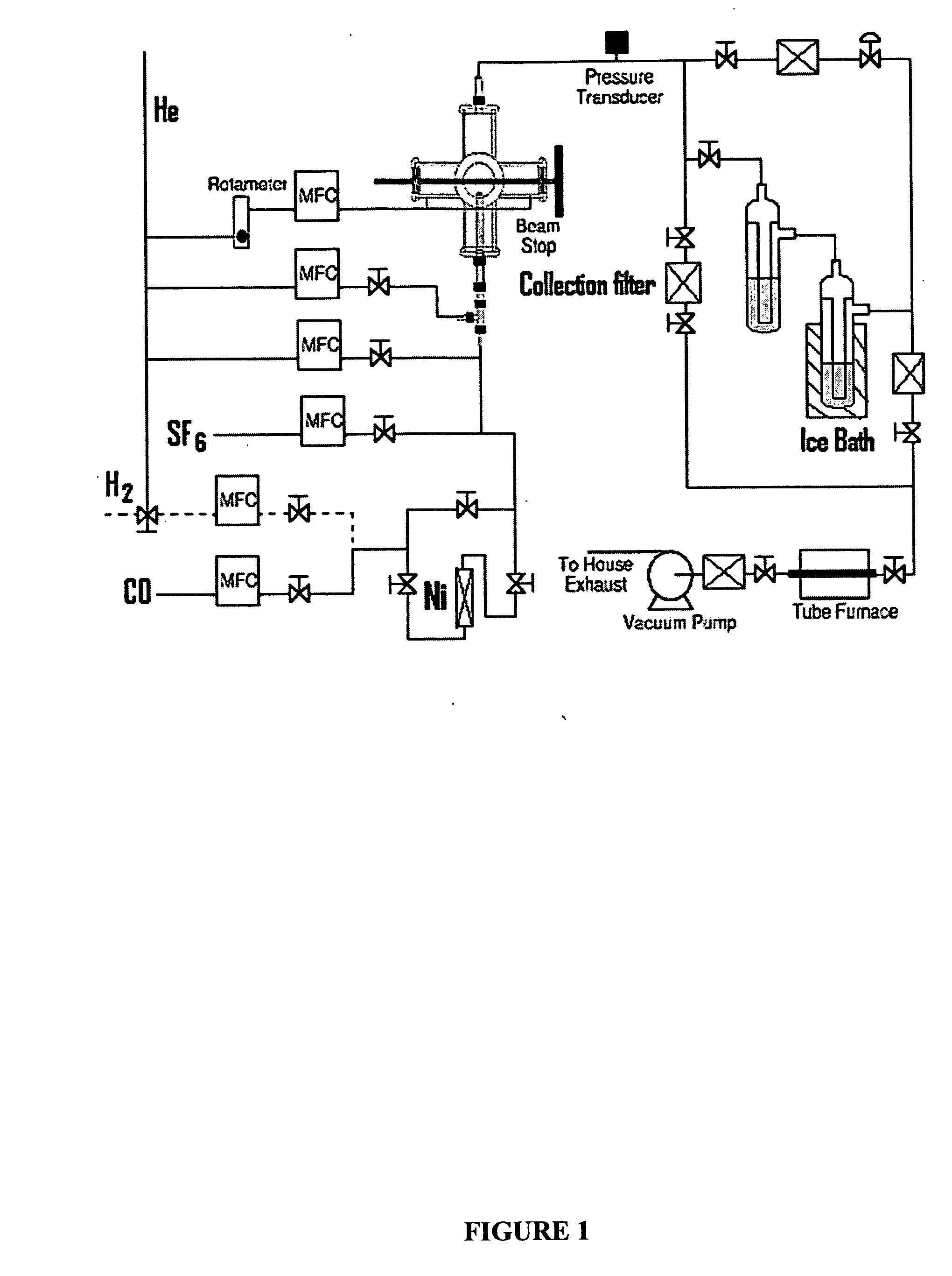

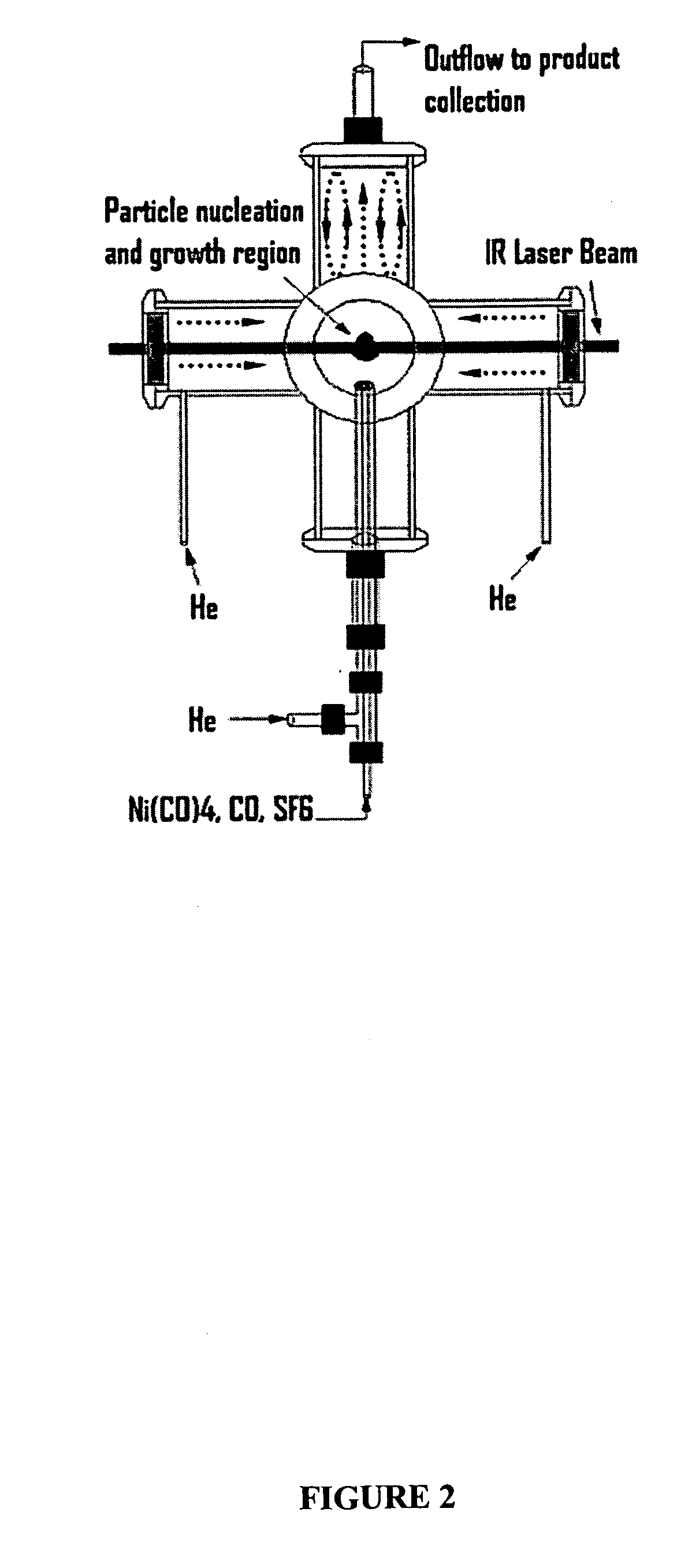

Production of nickel nanoparticles from a nickel precursor via laser pyrolysis

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

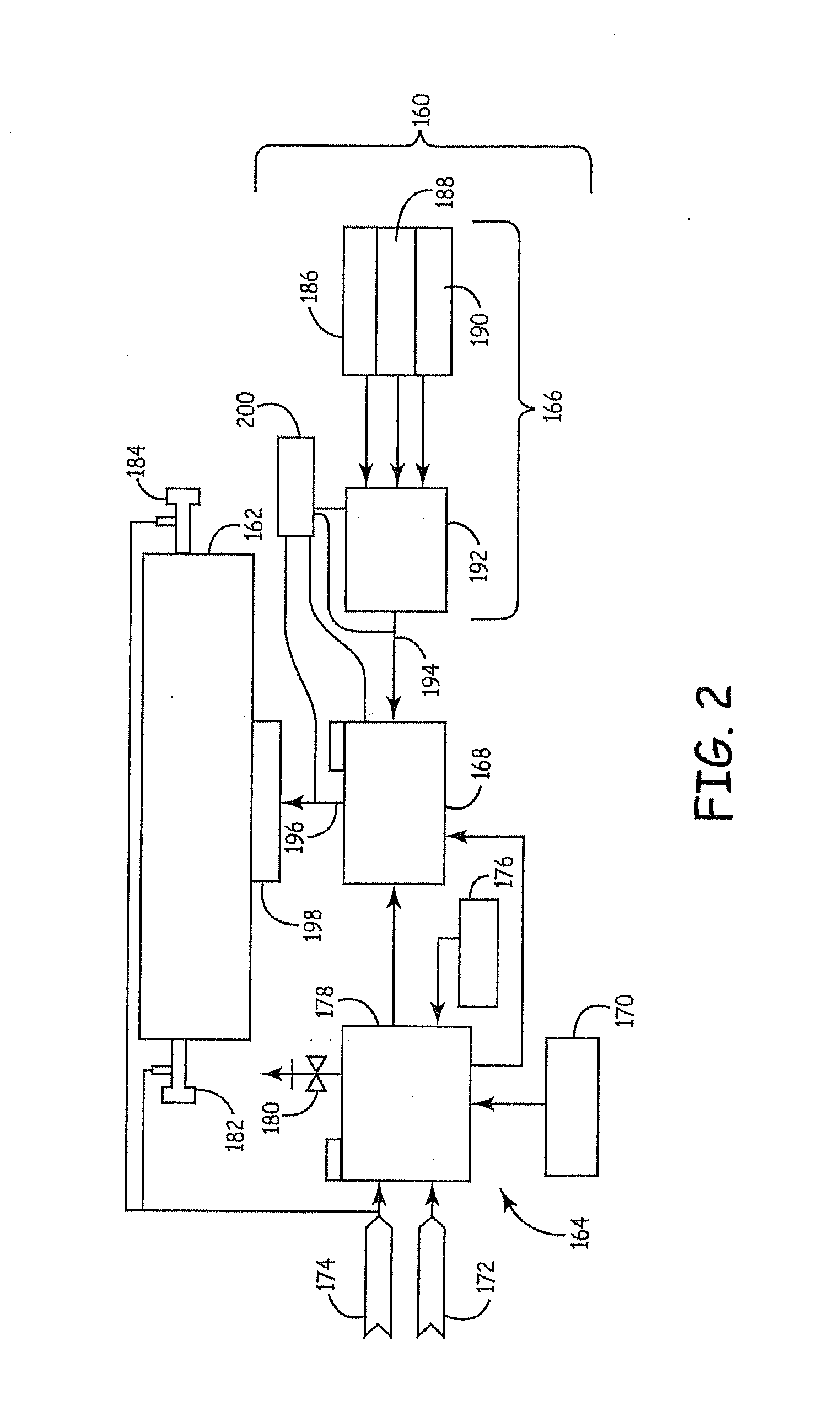

Synthesis of Nanoparticles by Laser Pyrolysis

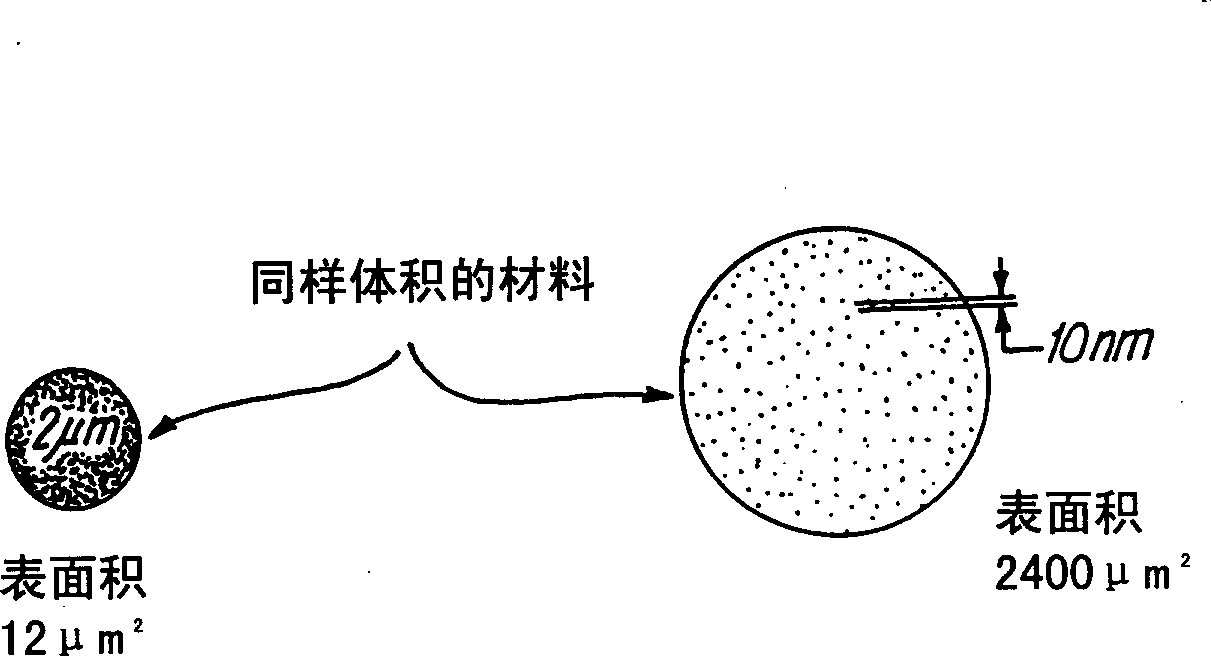

ActiveUS20100092367A1Good effectReduce dispersionMaterial nanotechnologyOxide/hydroxide preparationLiquid stateHydrolysis

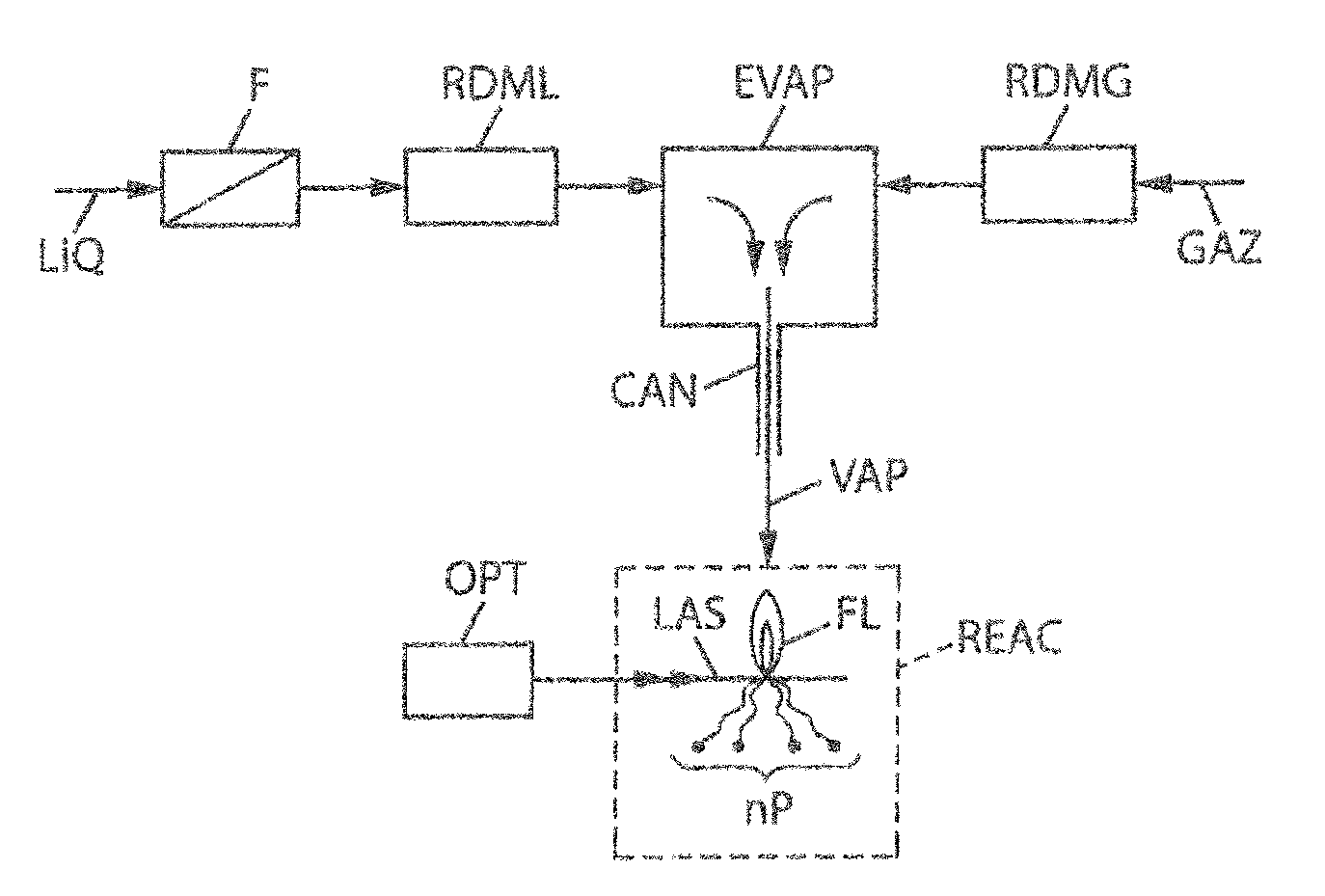

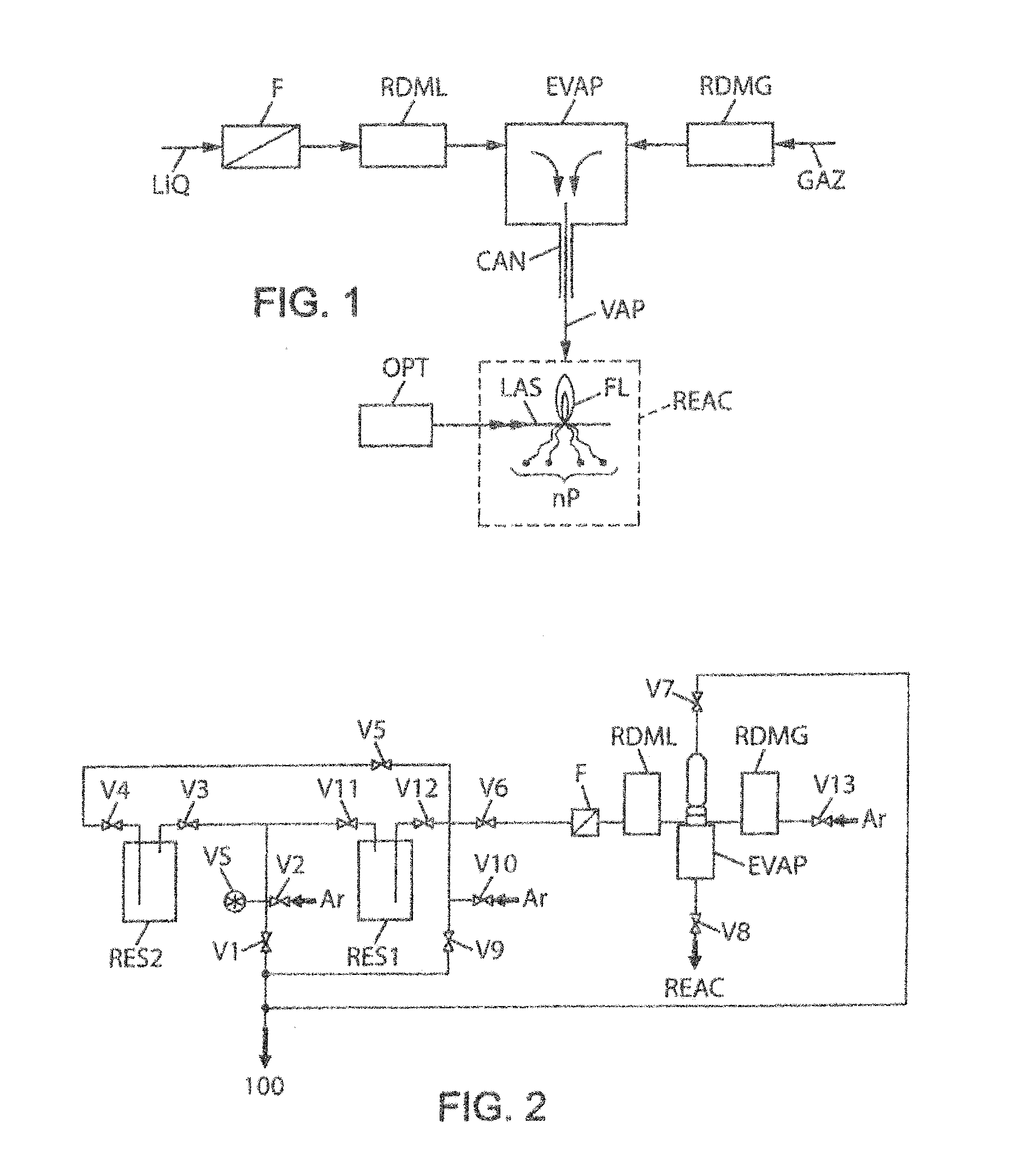

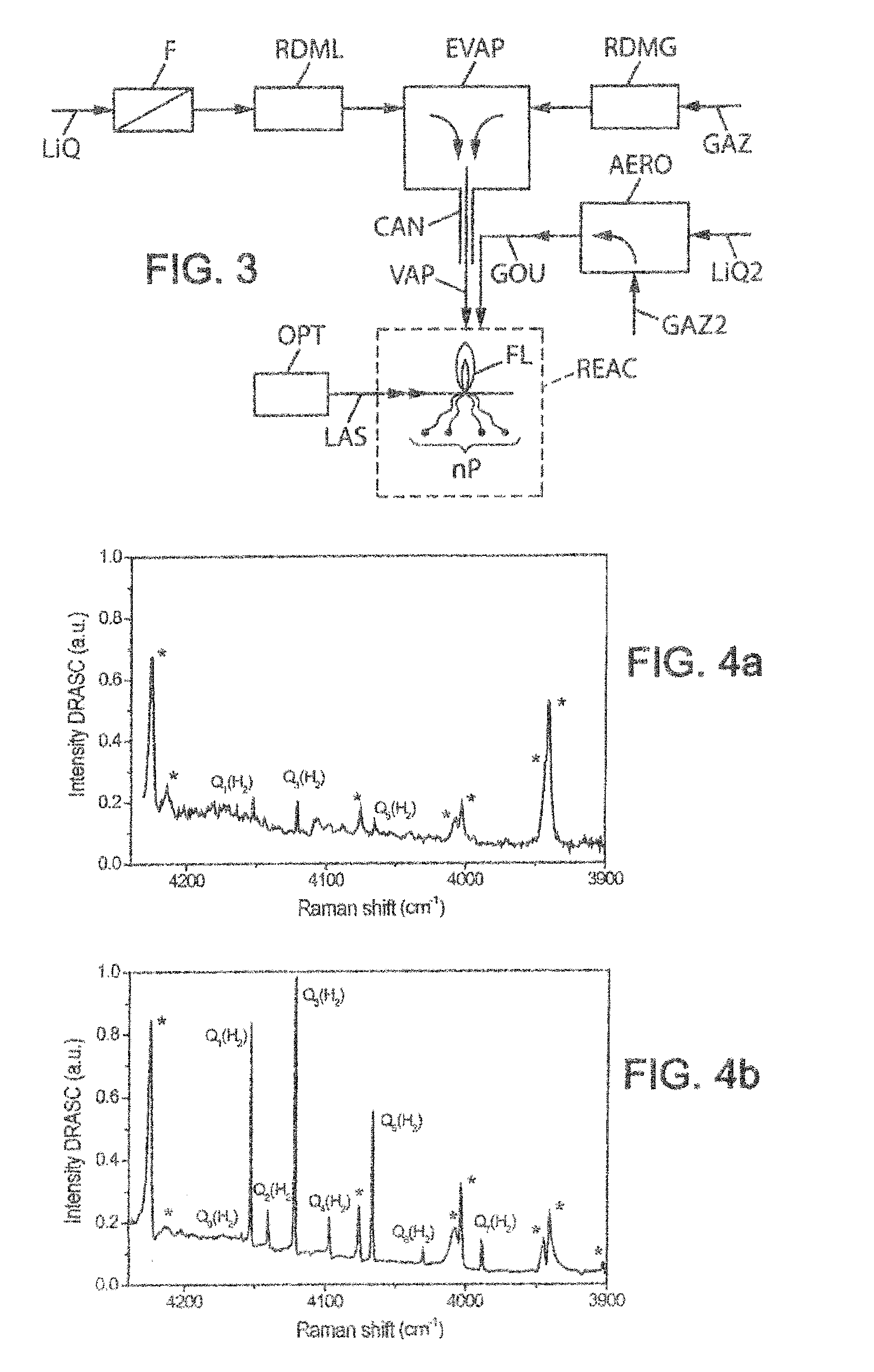

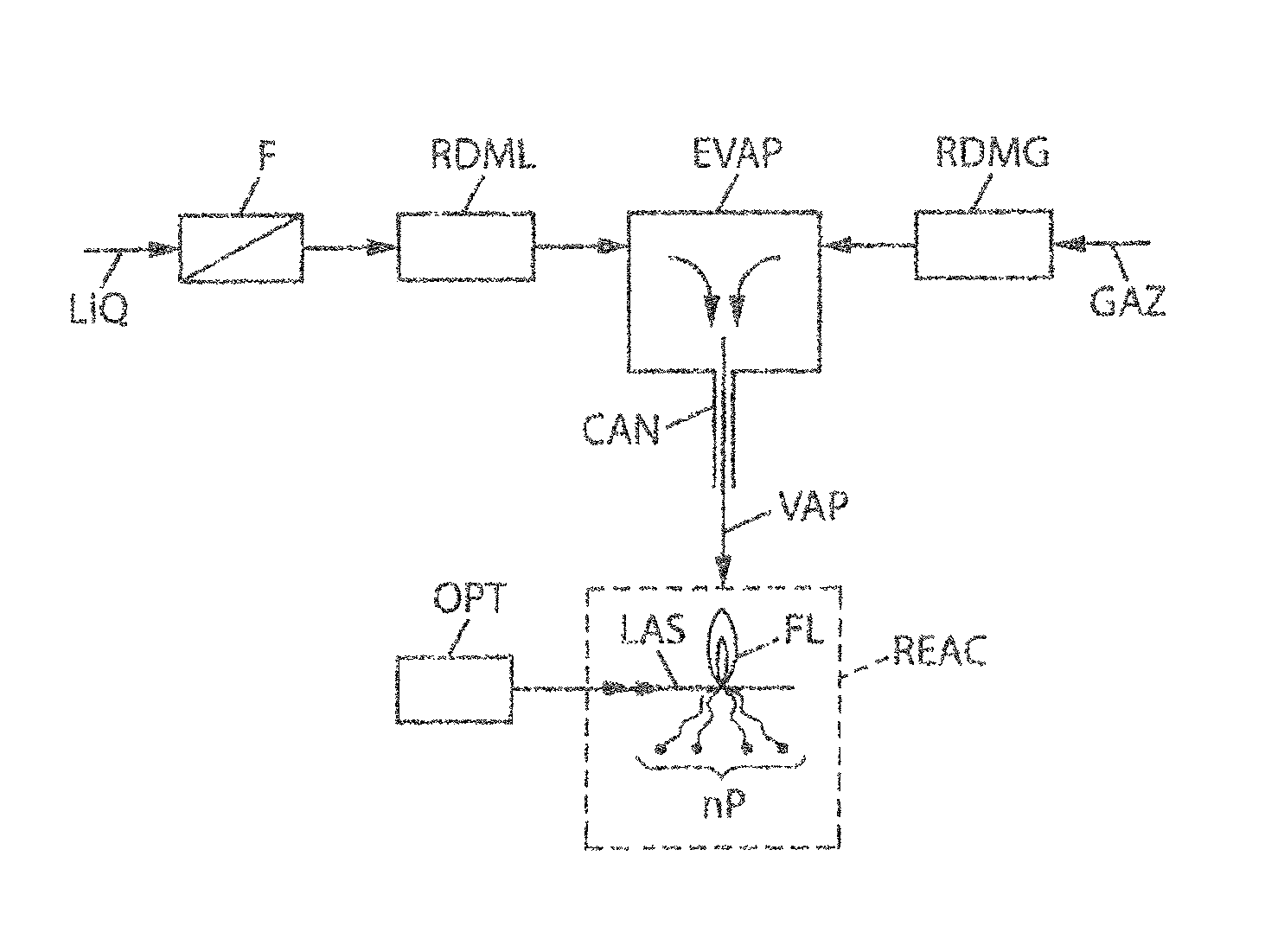

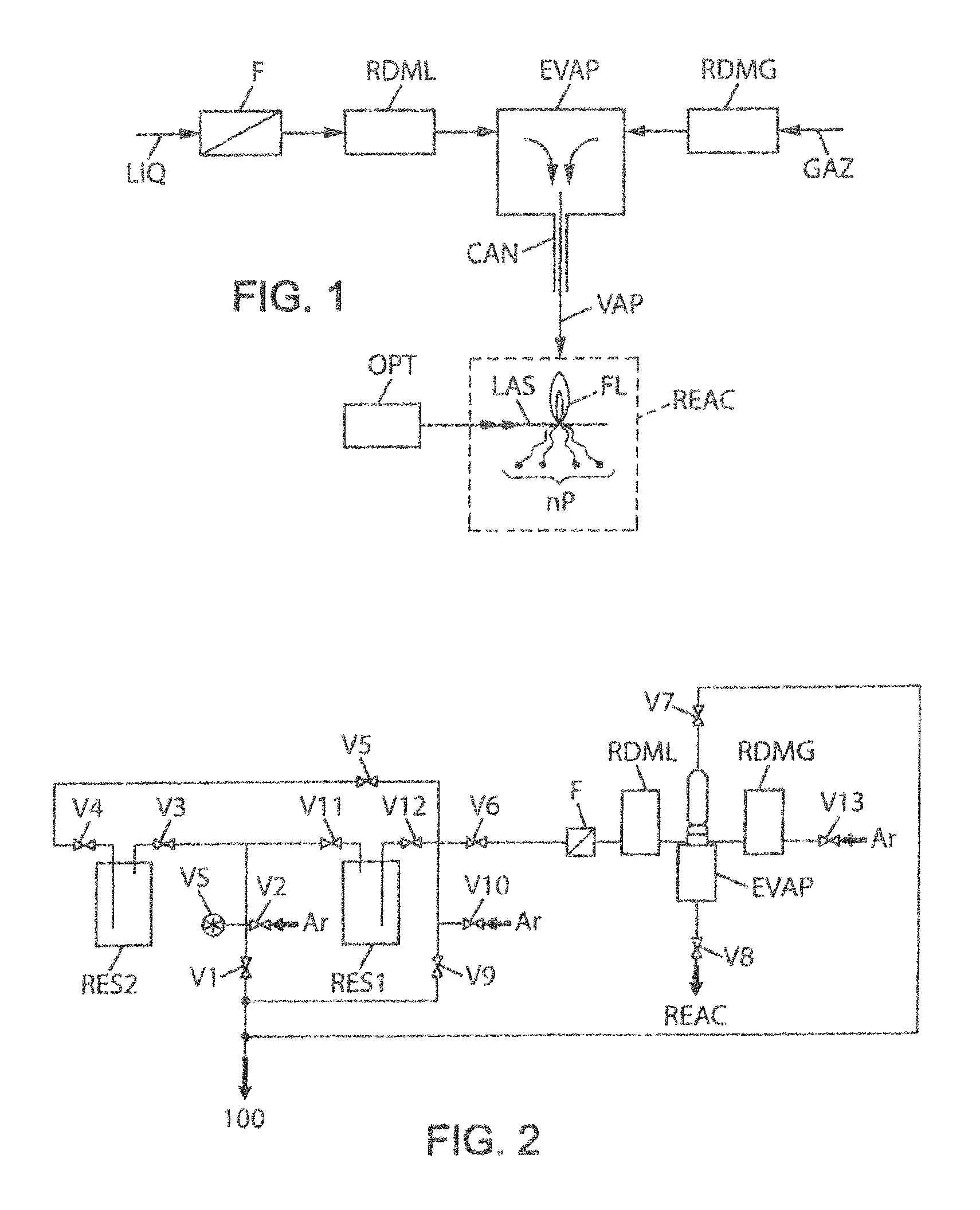

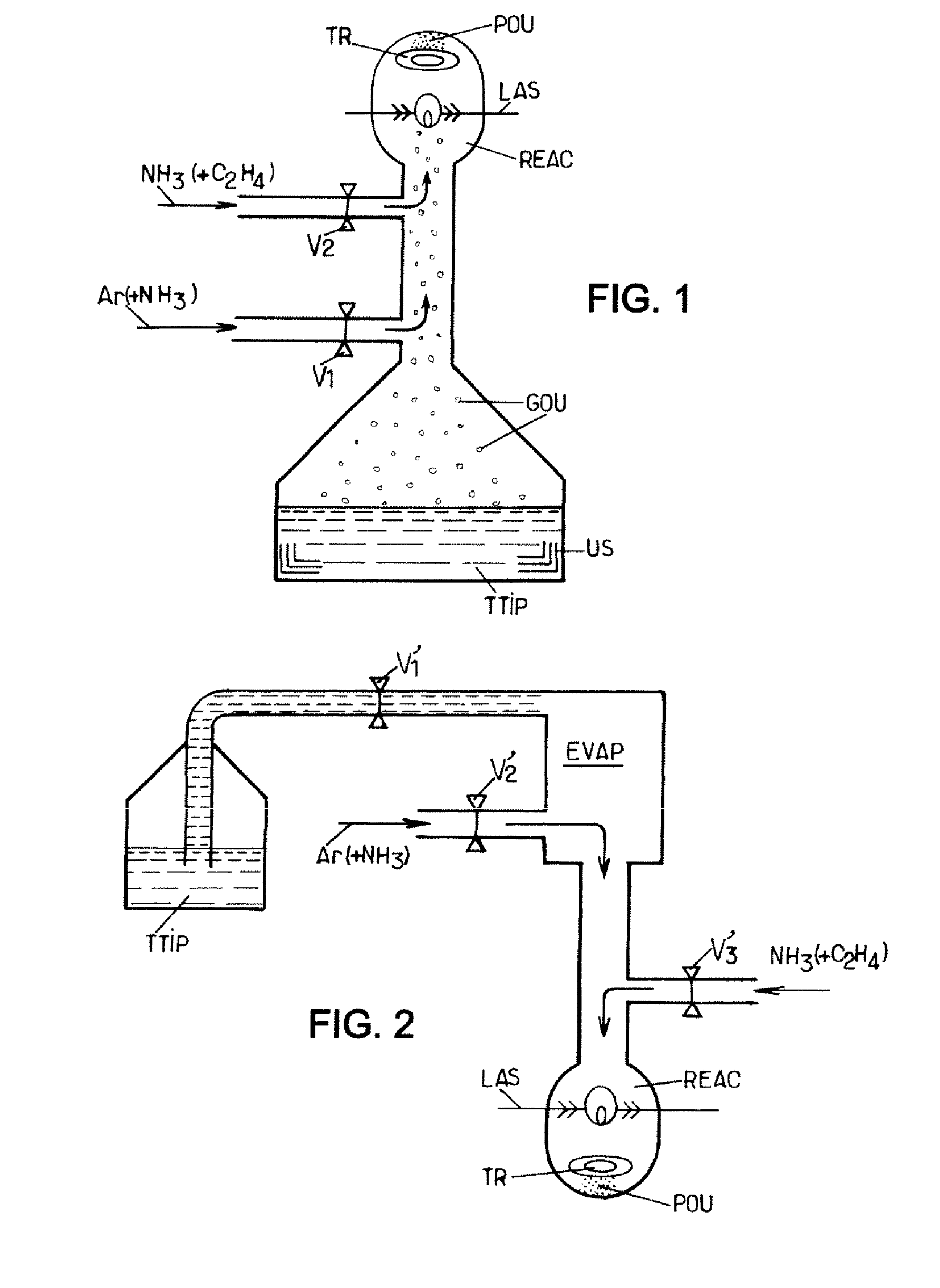

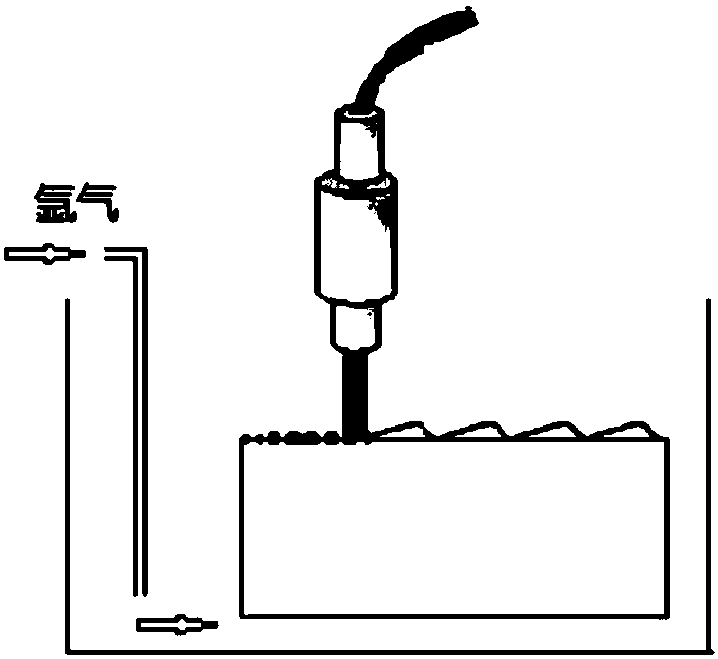

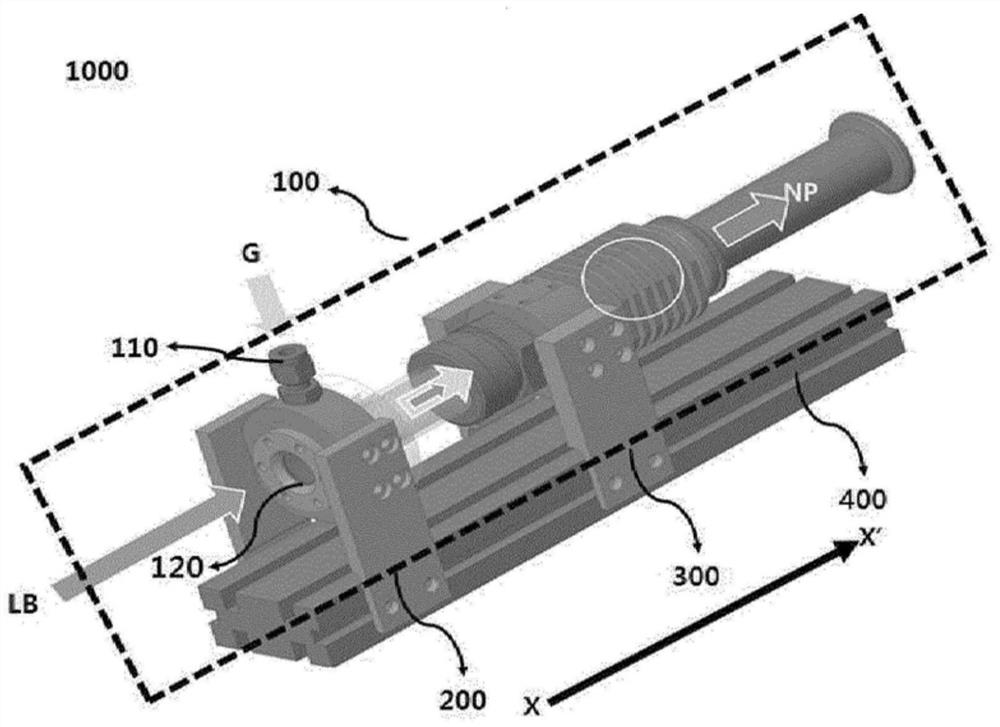

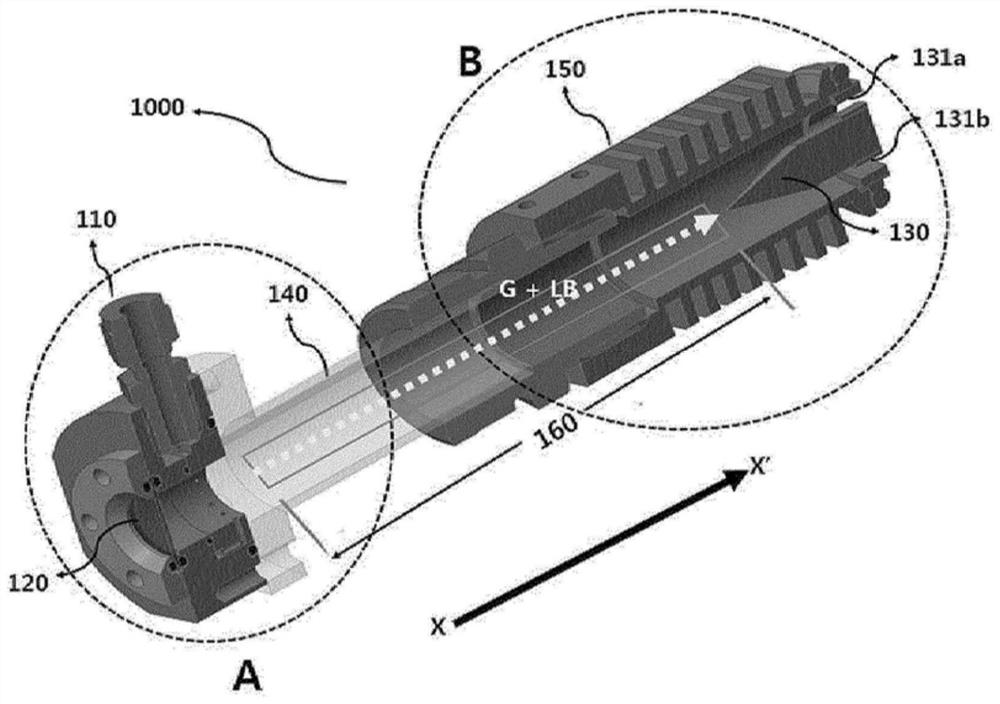

The present invention relates to the synthesis of nanoparticles by laser hydrolysis. For this purpose, a precursor interacts with a laser beam (LAS) in a pyrolysis reactor (REAC) for producing nanoparticles (nP), characterized in that the precursor is firstly in the liquid state and is then converted into the vapour phase and in that the flow rate of the precursor is controlled in the liquid phase.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Synthesis of nanoparticles by laser pyrolysis

ActiveUS8097233B2Good effectReduce dispersionMaterial nanotechnologyOxide/hydroxide preparationLiquid stateVapor phase

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

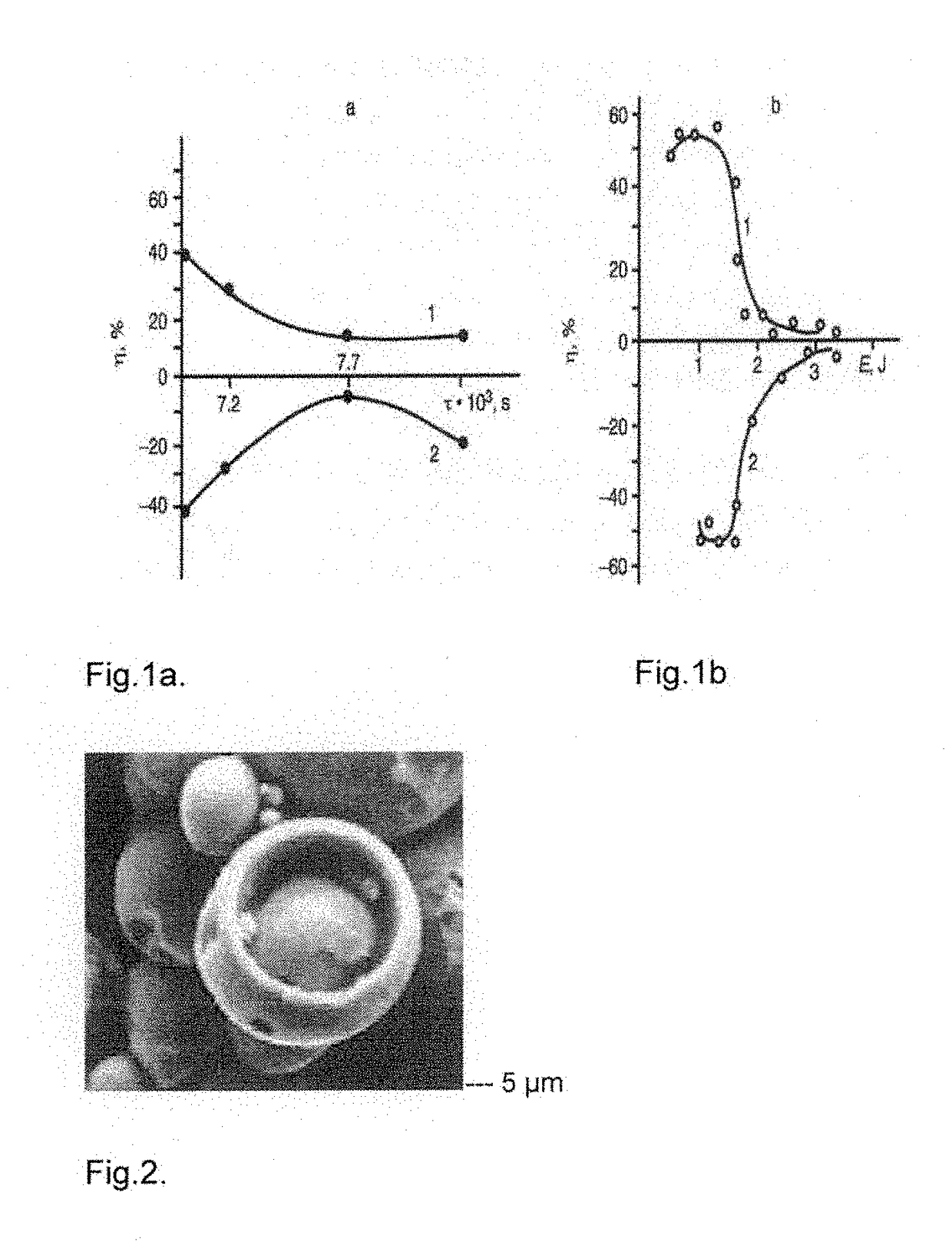

Laser pyrolysis method for producing carbon nano-spheres

InactiveUS7601321B2Superior purity and homogeneity and other propertyLow costMaterial nanotechnologyTransportation and packagingFuel cellsGraphite

The present invention encompasses methods and apparatus for creating metal nanoparticles embedded in a carbonaceous char, the conversion of an carbonaceous char with embedded metallic nanoparticles to graphite-encased nano-sized metal particles surrounded by char, the separation of the graphite encased metal particles from the char matrix, and the related preparation and isolation of carbon nanosphere materials with or without the enclosed metal nanoparticles, and the uses of such carbon nanospheres and graphite enclosed metal nanoparticles as supports and enhancers for fuel cell electrocatalysts and other applications.

Owner:MCKINNON J THOMAS +2

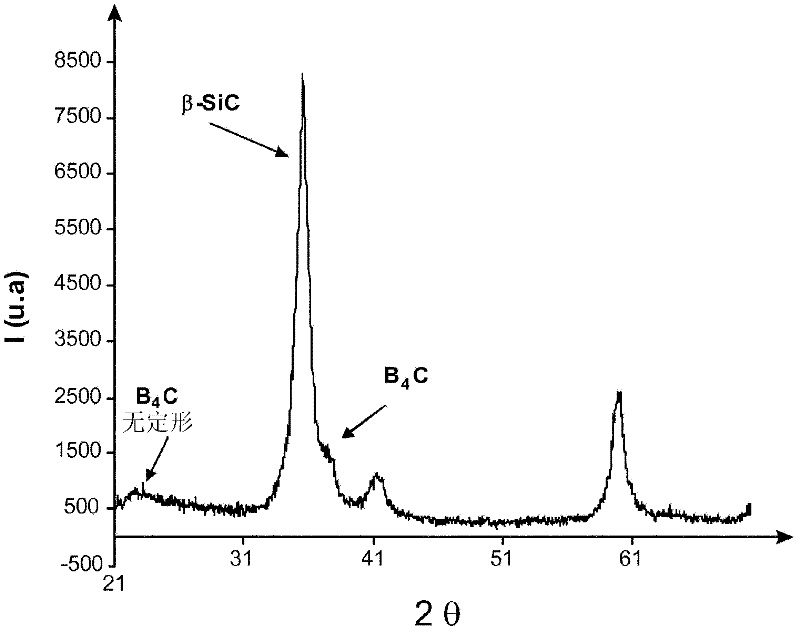

Method for producing a powder including carbon, silicon and boron

The invention relates to a method for producing a powder including carbon, silicon and boron, the silicon being in the form of silicon carbide and the boron being in the form of boron carbide and / or free boron, including the following steps: a step of placing in contact a carbon-based precursor, a silicon-based precursor and a boron-based precursor BX3, where X is a halogen atom, such as to obtain a mix of said three precursors; a step of subjecting the resulting mixture to laser pyrolysis, the boron-based precursor BX3 being heated, prior to the step of placing in contact and / or simultaneously with the step of placing in contact, to a temperature higher than the condensation temperature of said precursor.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Ultraviolet light block and photocatalytic materials

InactiveUS20050232878A1Small sizeCosmetic preparationsToilet preparationsUltraviolet lightsPhotoresist

Nanoscale UV absorbing particles are described that have high UV absorption cross sections while being effectively transparent to visible light. These particles can be used to shield individuals from harmful ultraviolet radiation. These particles can also be used in industrial processing especially to produce solid state electronic devices by creating edges of photoresist material with a high aspect ratio. The UV absorbing particles can also be used as photocatalysts that become strong oxidizing agents upon exposure to LV light. Laser pyrolysis provides an efficient method for the production of suitable particles.

Owner:NANOGRAM

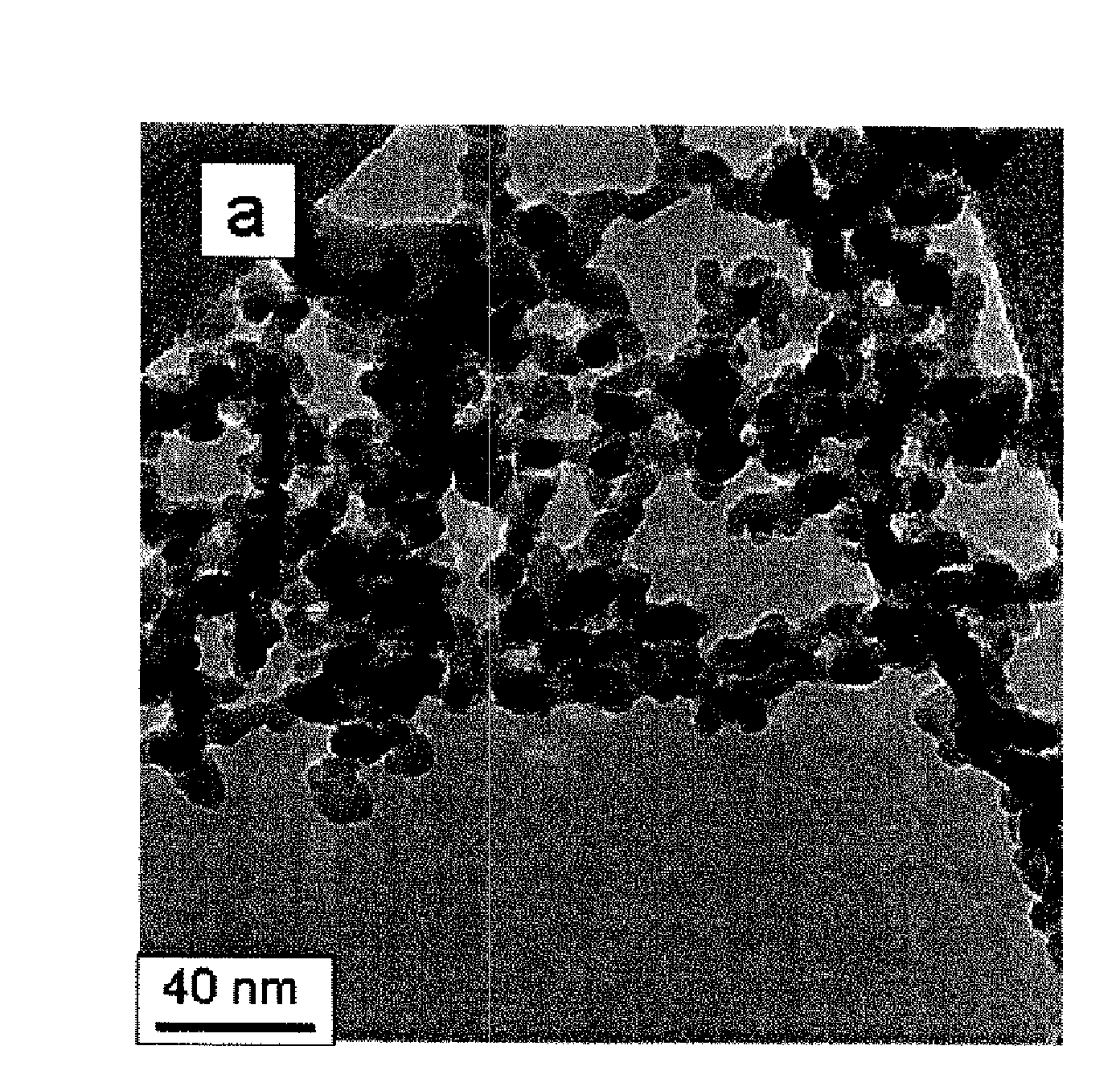

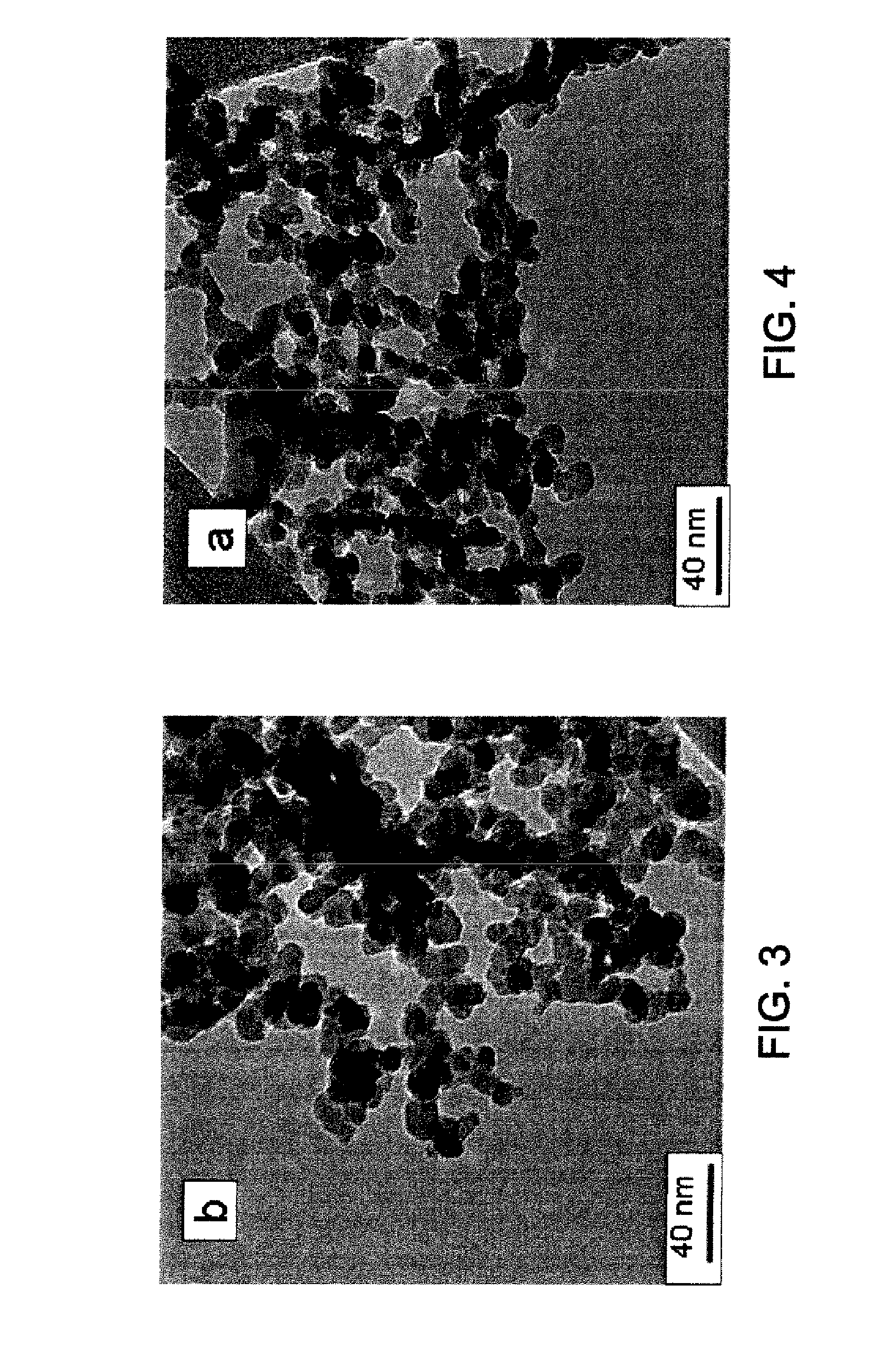

Method for the synthesis of ticon, tion and tio nanoparticles by laser pyrolysis

The invention relates to the synthesis of a material including nanoparticles containing oxygen, titanium and nitrogen. According to the invention the method comprises the combustion by a temperature rise of at least 500° C. of a precursor containing at least titanium, oxygen and nitrogen. Advantageously, the combustion can be a laser pyrolysis and ammonia can be used both as a reagent supplying the nitrogen element for sensitising the pyrolysis reaction and as a fluid for carrying another reagent supplying the titanium element.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Process for selective deep hydrodesulfurization of a hydrocarbon feedstock using an unsupported nanocatalyst made by laser pyrolysis

InactiveUS20170369792A1Catalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNano catalystHydrodesulfurization

A process for producing an unsupported molybdenum sulfide nanocatalyst comprising atomizing a molybdenum oxide solution to form a molybdenum oxide aerosol, pyrolyzing the molybdenum oxide aerosol with a laser beam to form the unsupported molybdenum-based nanocatalyst, and pre-sulfiding at least a portion of the unsupported molybdenum-based nanocatalyst to form an unsupported molybdenum sulfide nanocatalyst, wherein the unsupported molybdenum-based nanocatalyst, the unsupported molybdenum sulfide catalyst or both are in the form of nanoparticles with a diameter of 1-10 nm and in a distorted rutile crystalline structure. A method of selective deep hydrodesulfurization whereby a hydrocarbon feedstock having at least one sulfur-containing component and at least one hydrocarbon is contacted with the unsupported molybdenum sulfide nanocatalyst.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

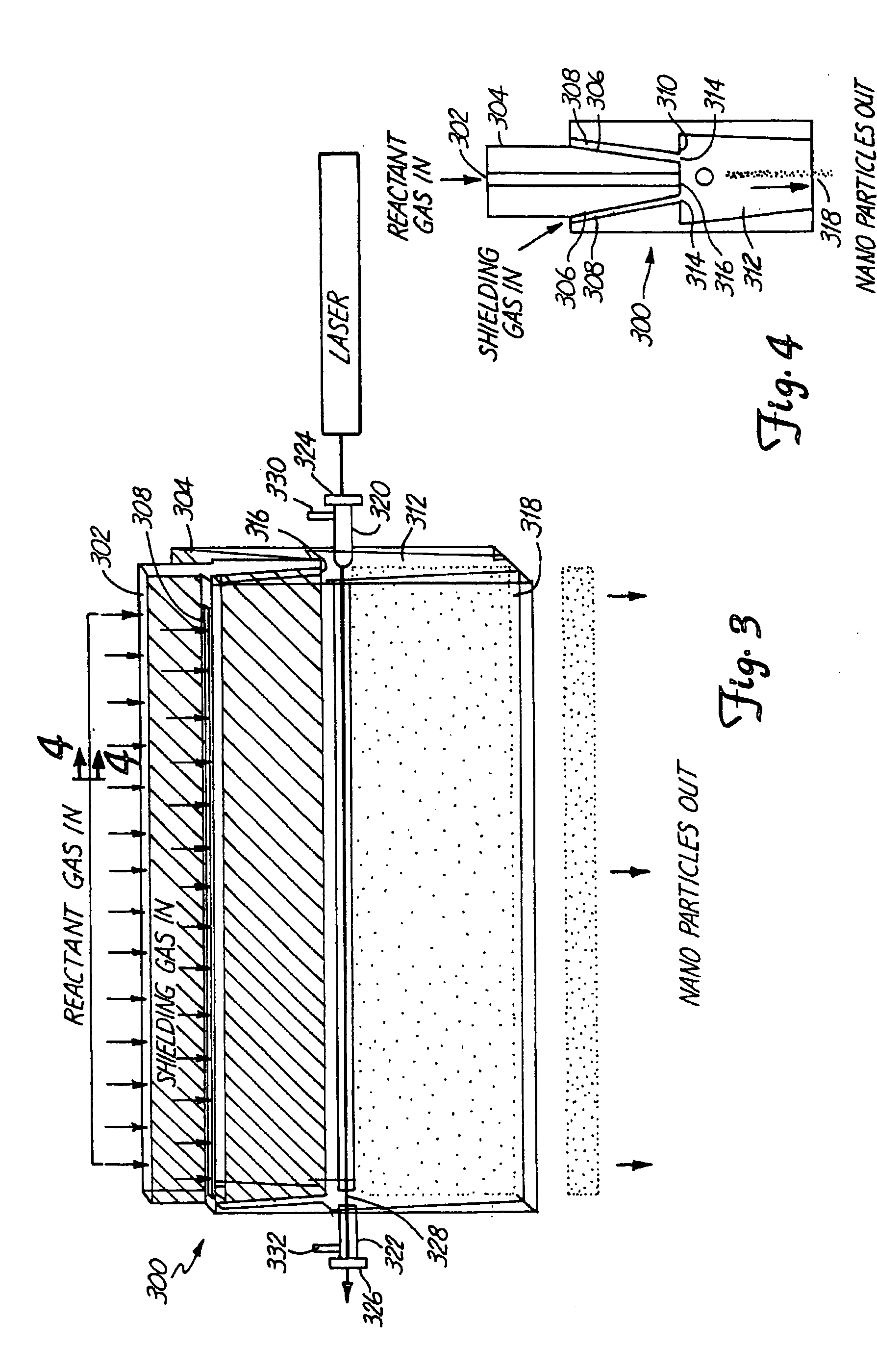

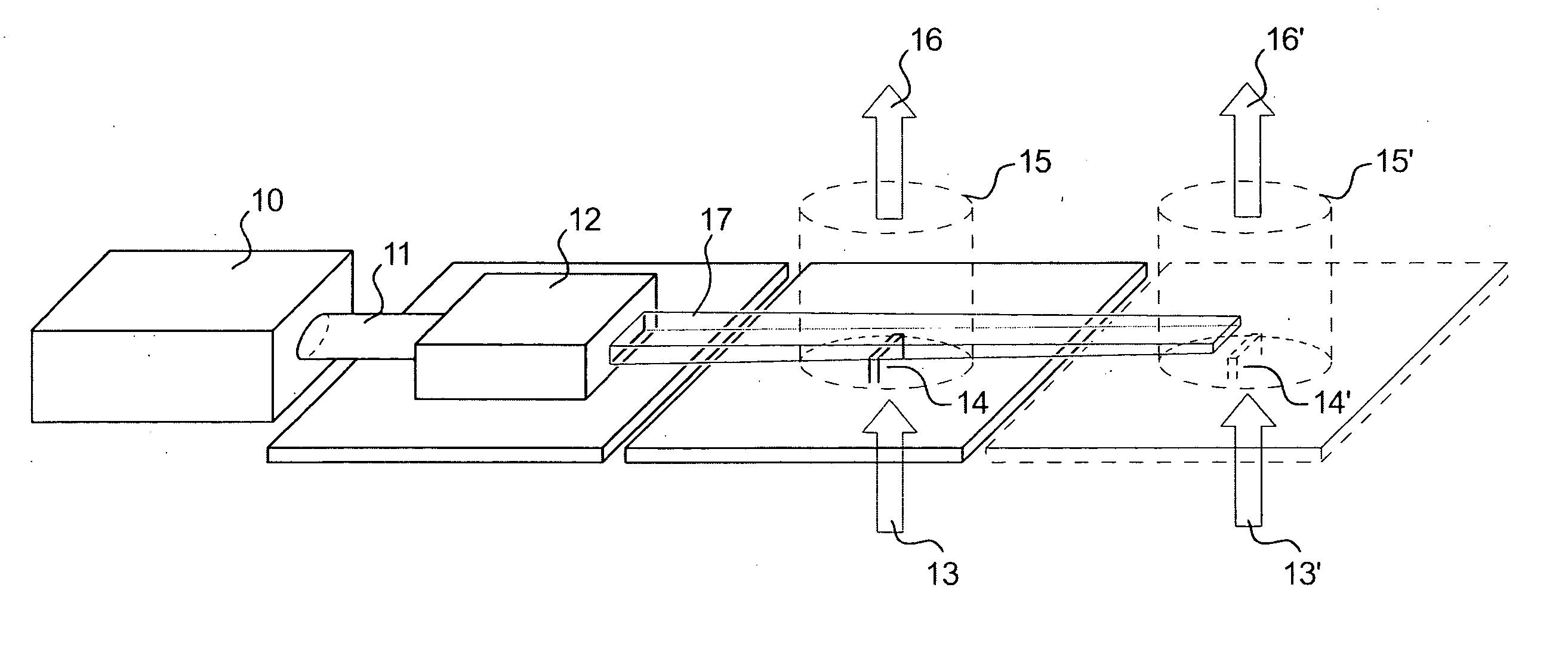

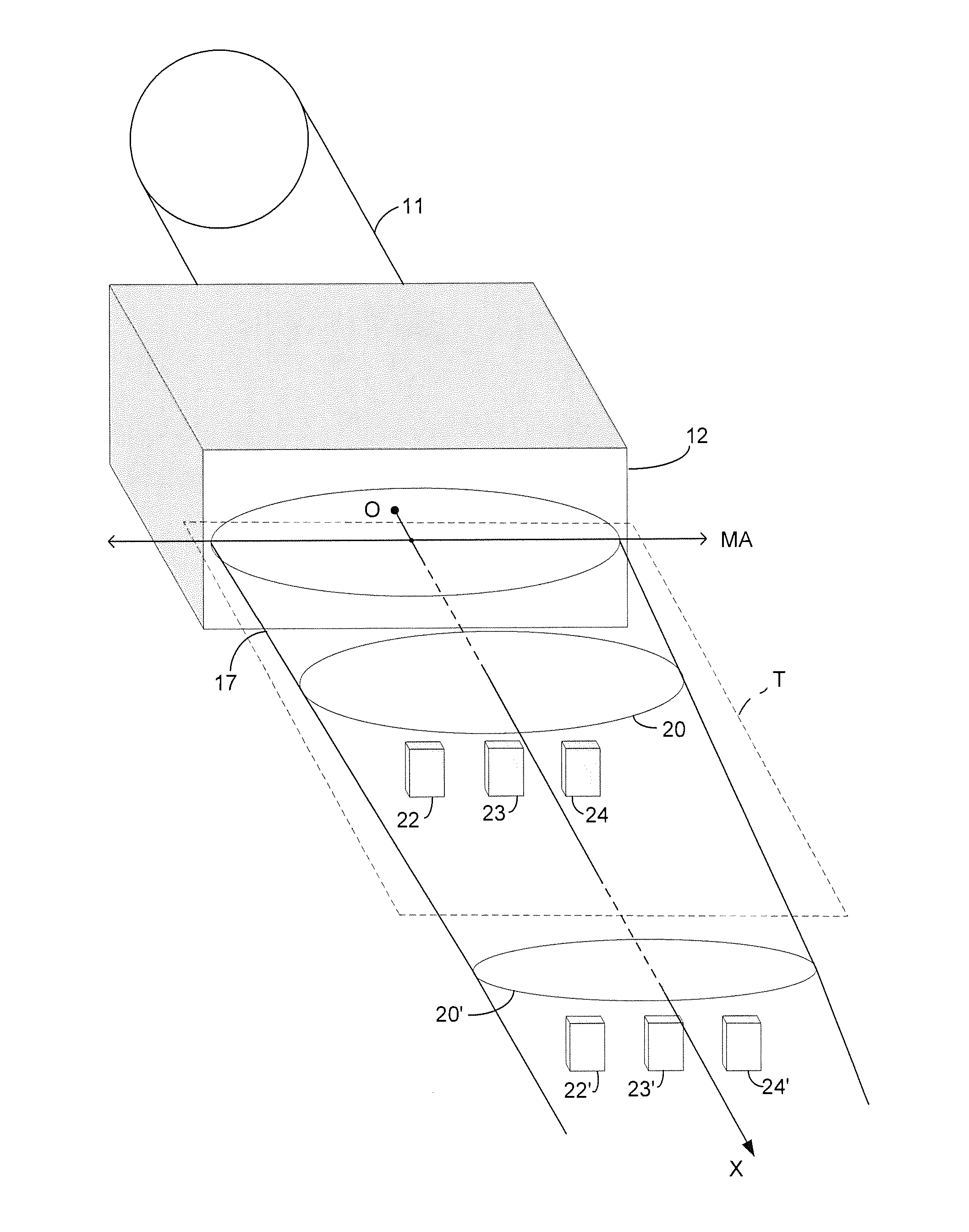

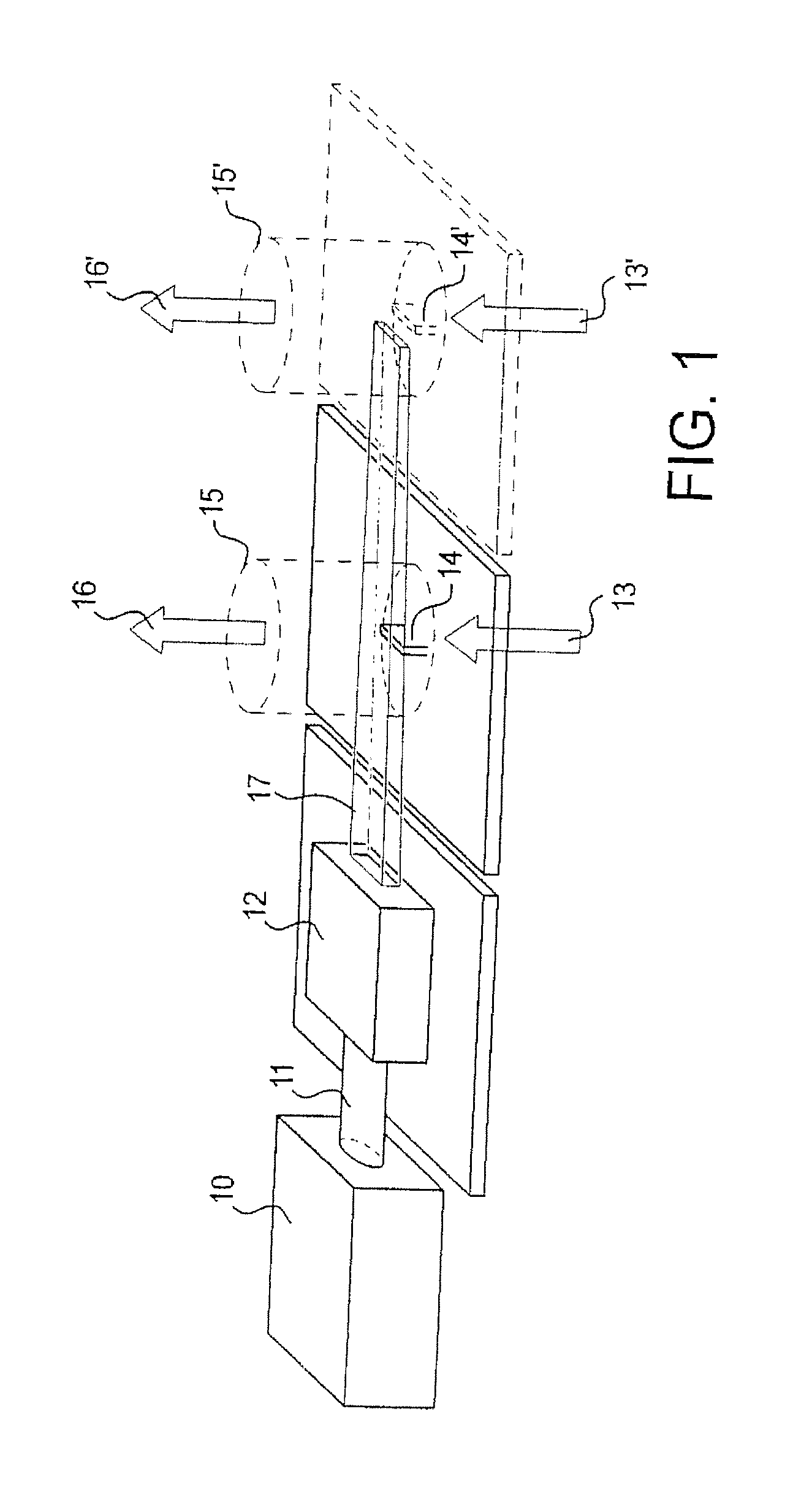

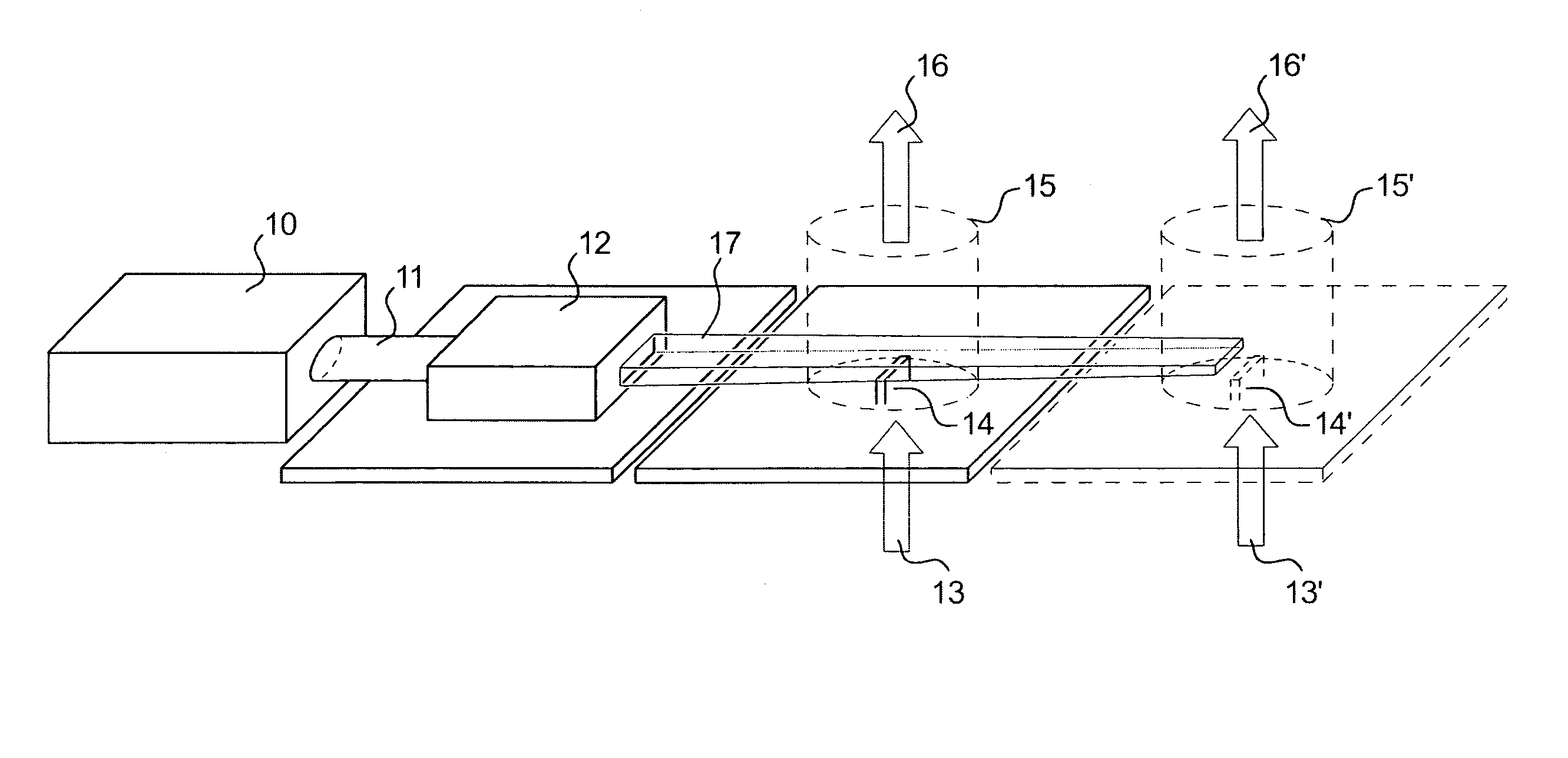

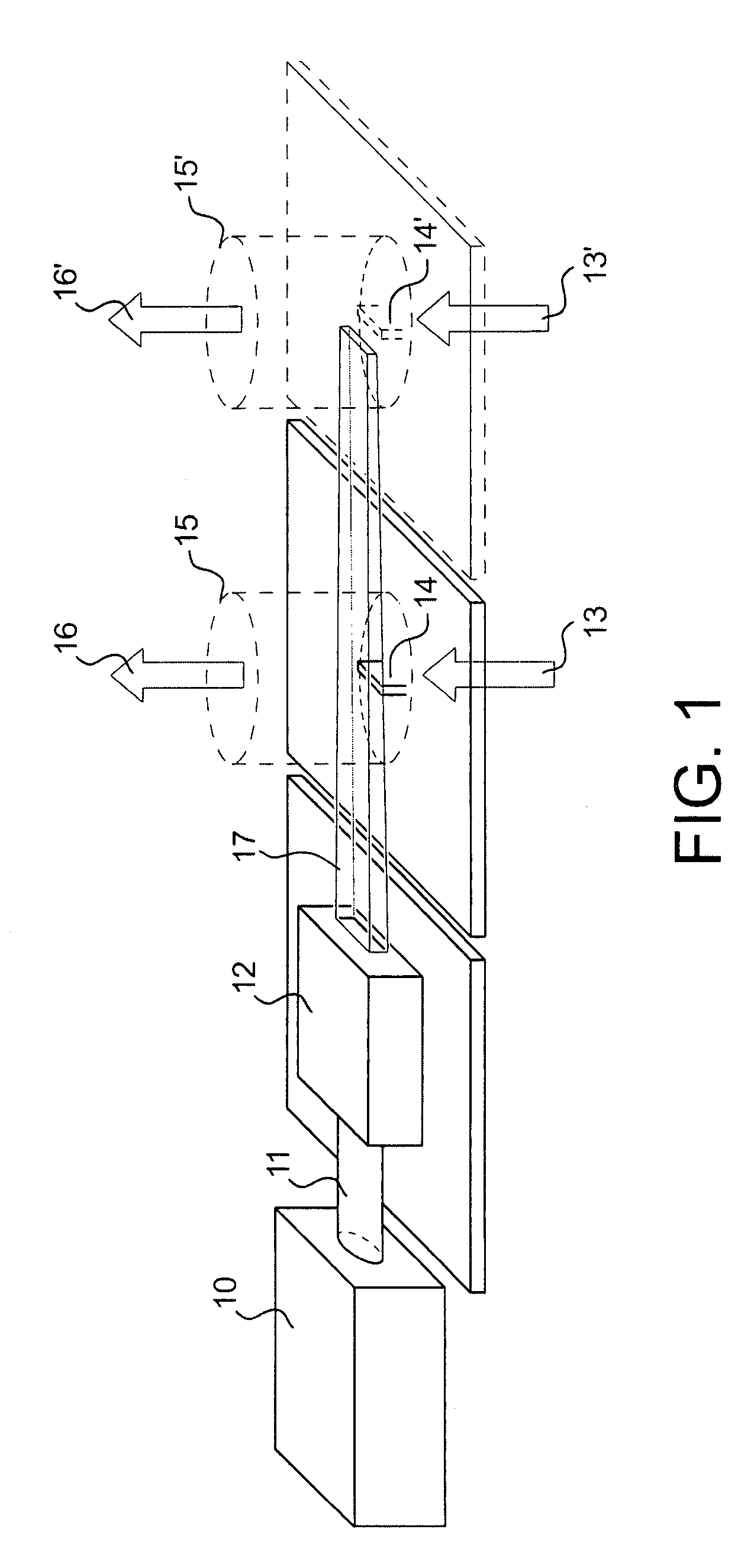

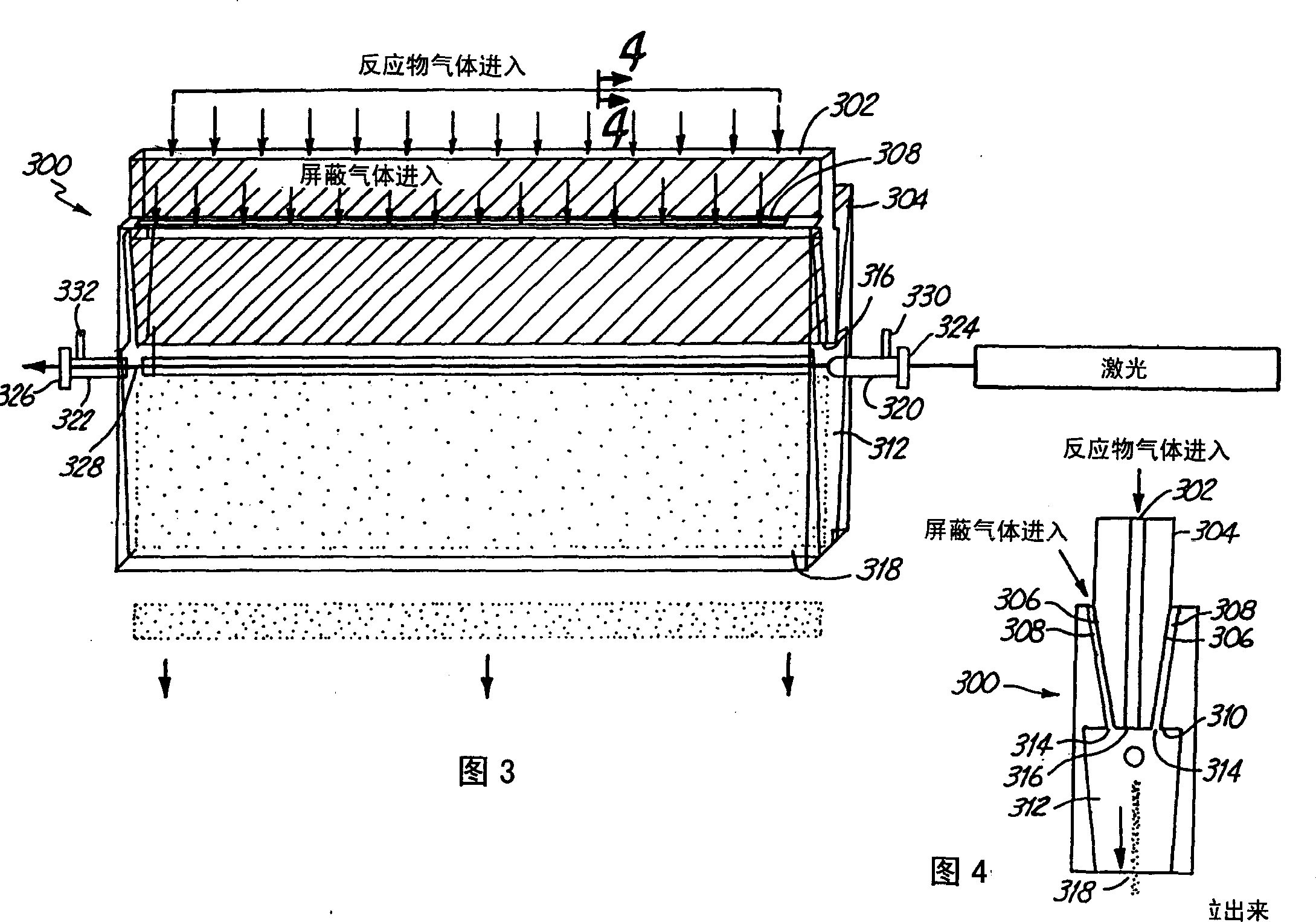

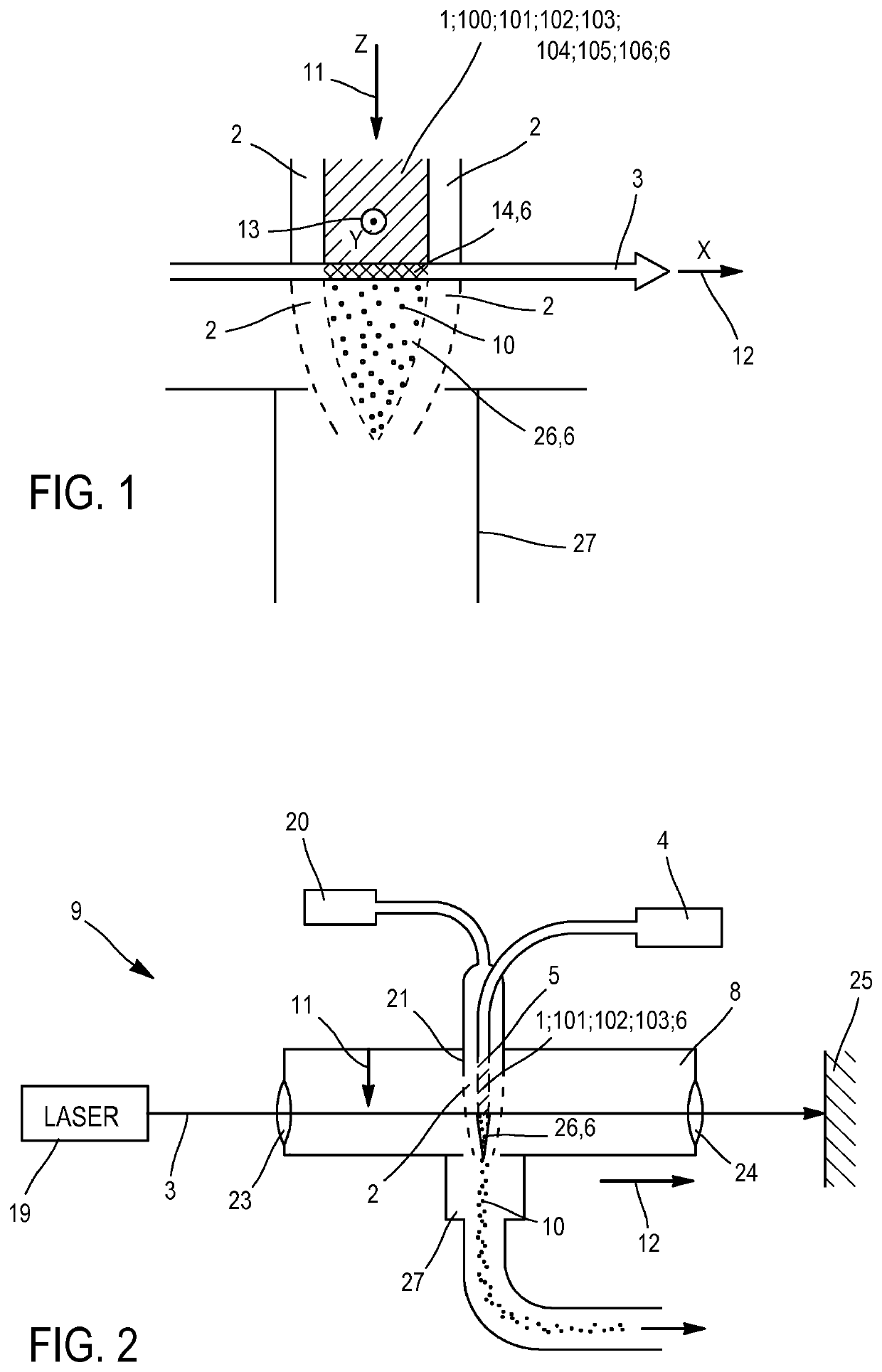

System and Process for Production of Nanometric or Sub-Micrometric Powders in Continuous Flus Under the Action of a Pyrolysis Laser

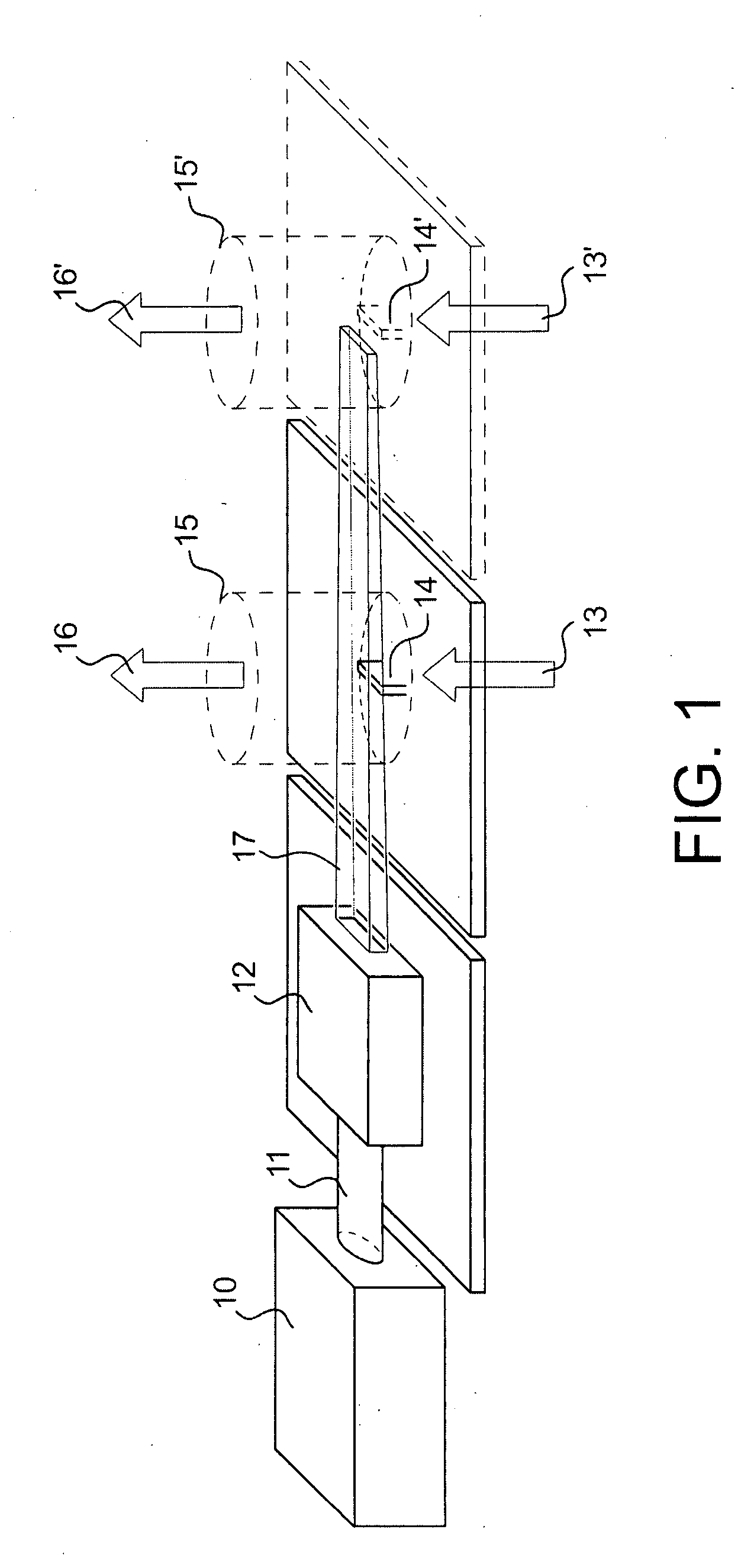

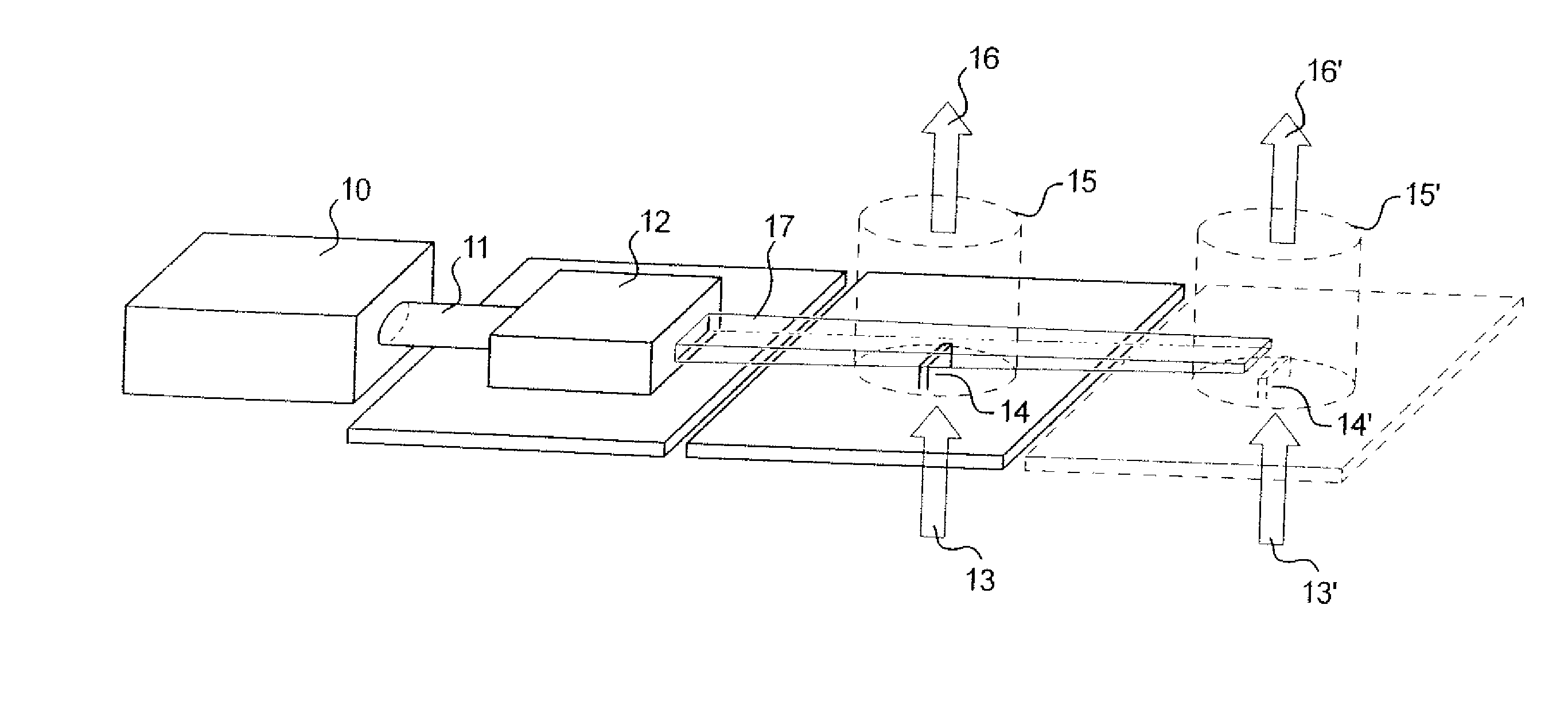

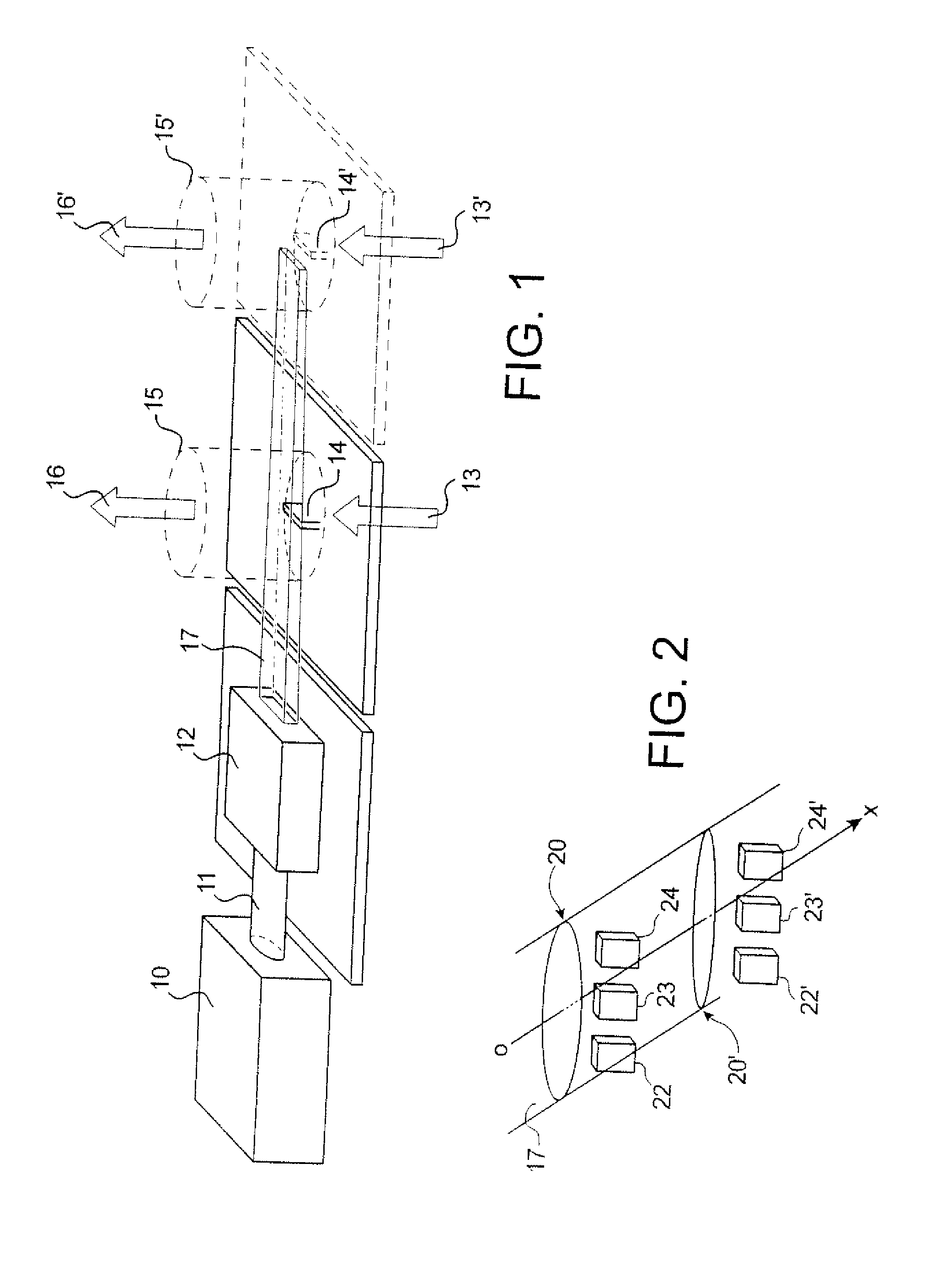

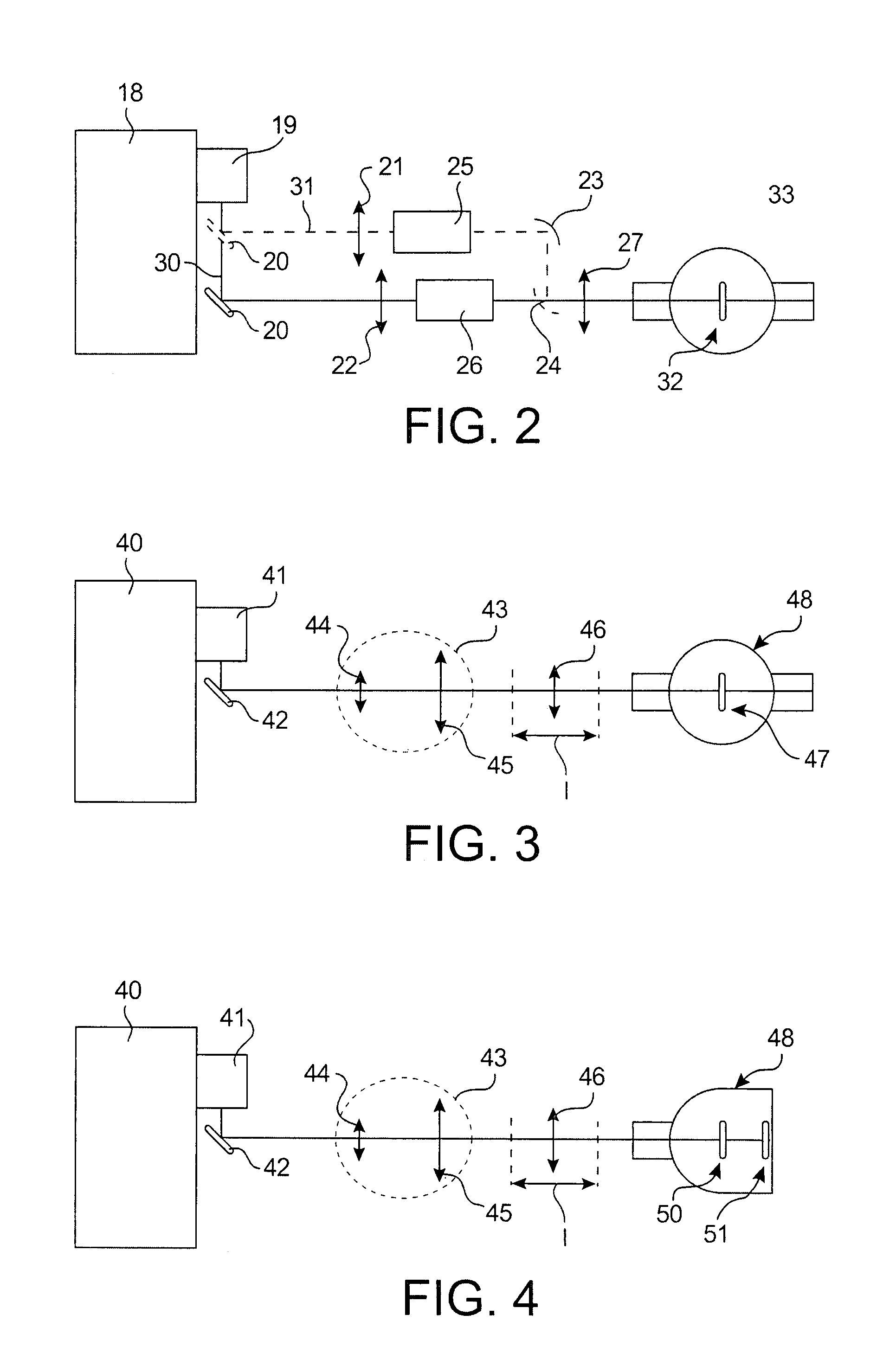

ActiveUS20070295702A1High temperature gas-gas reactionChemical/physical/physico-chemical processesLight beamLaser pyrolysis

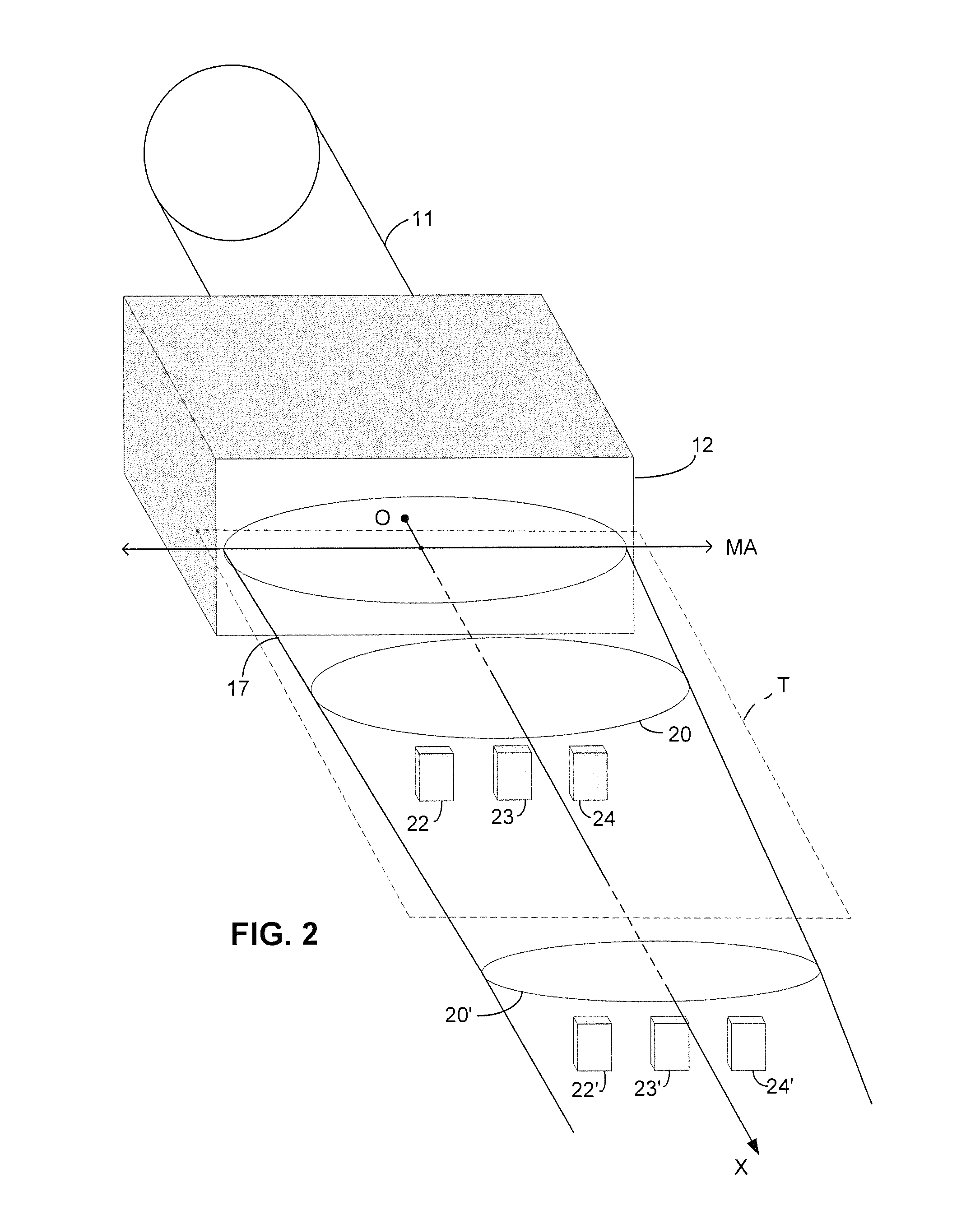

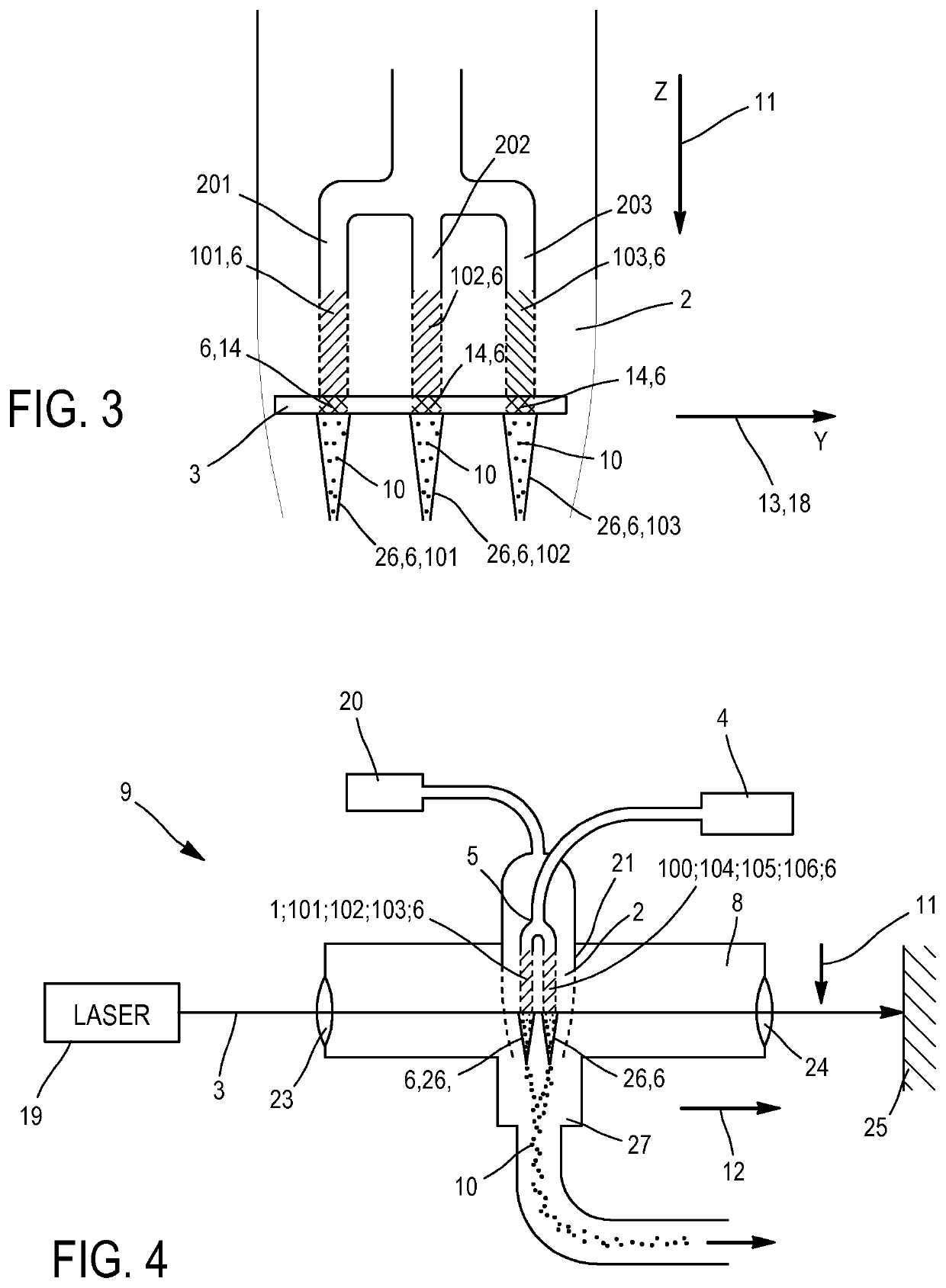

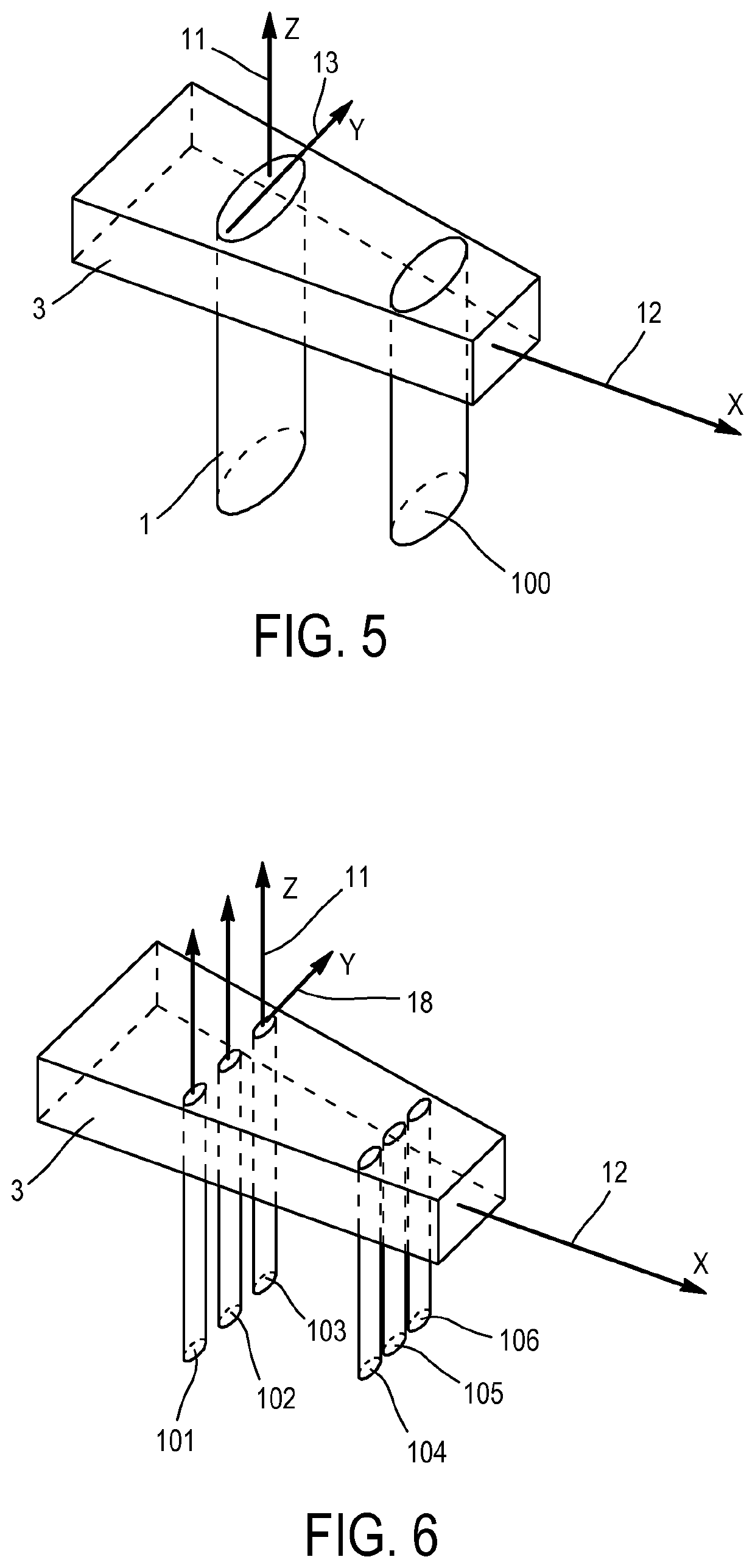

The invention relates to a system for production of nanometric or sub-micrometric powders in continuous flux under the action of laser pyrolysis in at least one interaction zone between a beam (11) emitted by a laser (10) and a flux of reagents (13) emitted by an injector (14), in which the laser is followed by optical means (12) for distributing the energy of the beam emitted by the latter according to an axis perpendicular to the axis of each flux of reagents, in an elongated cross-section having adjustable dimensions at the level of this at least one interaction zone. It also relates to a process for production of such powders.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

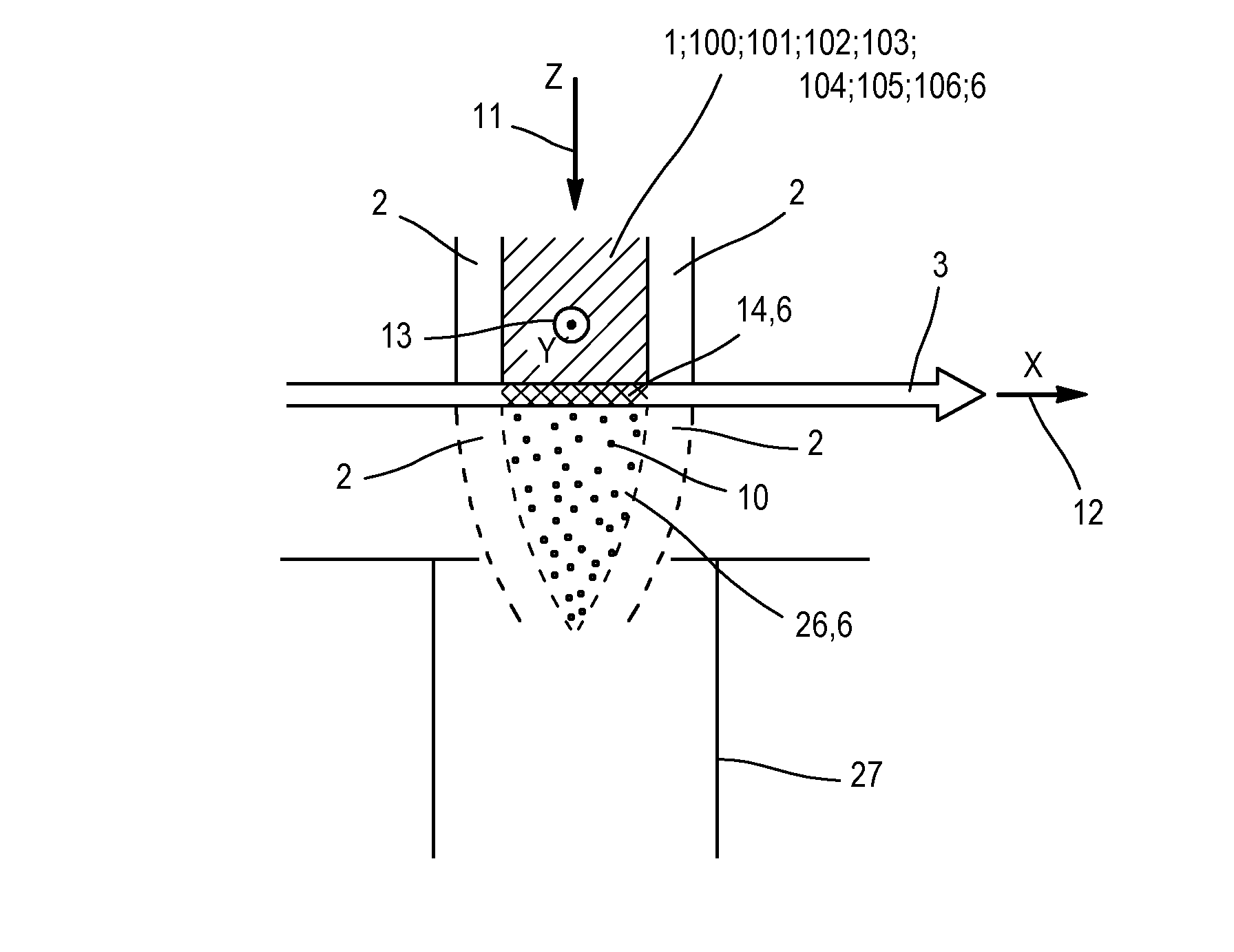

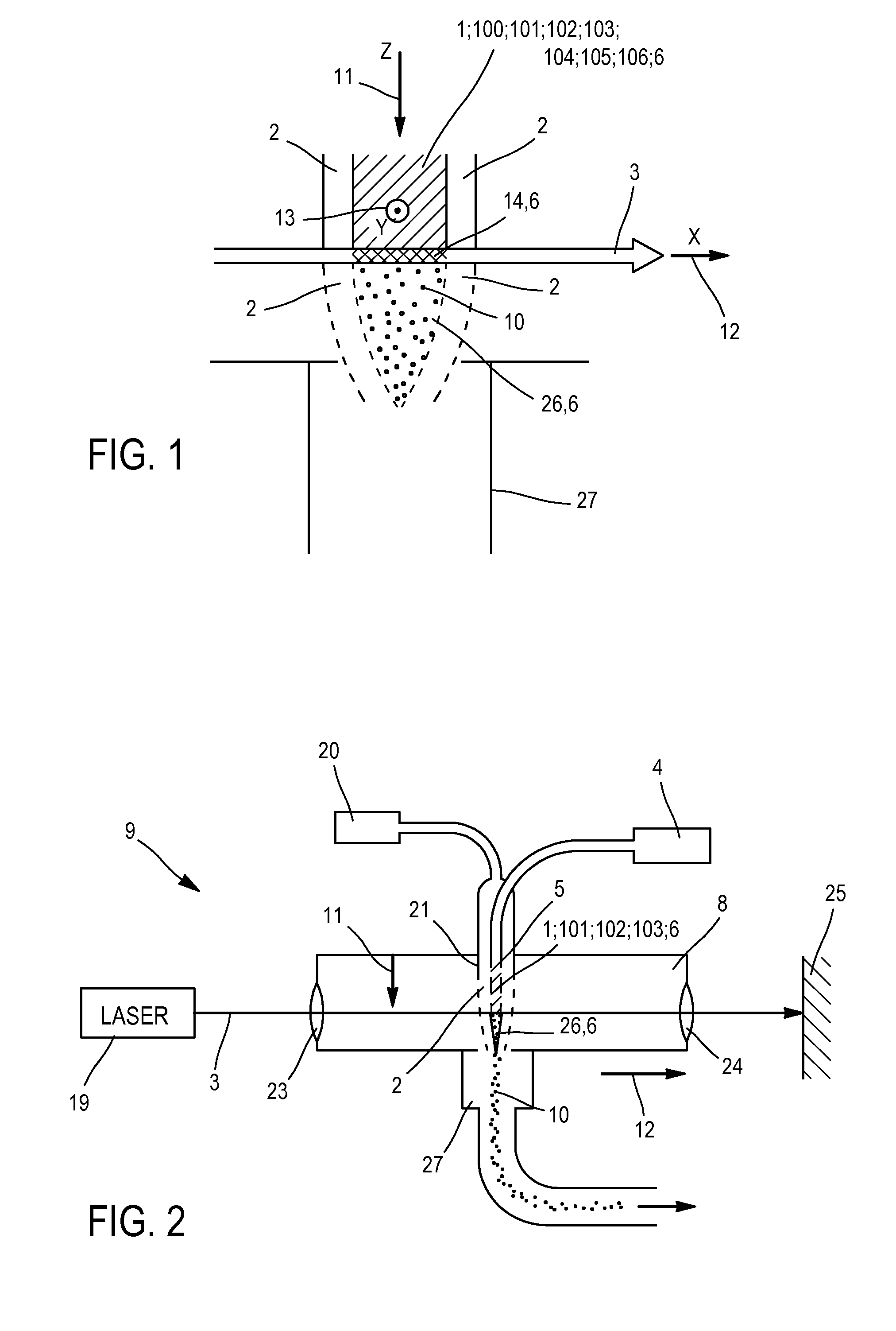

System And Method For Continuous Flow Production of Nanometric Or Sub-Micrometric Powders By The Action of Laser Pyrolysis

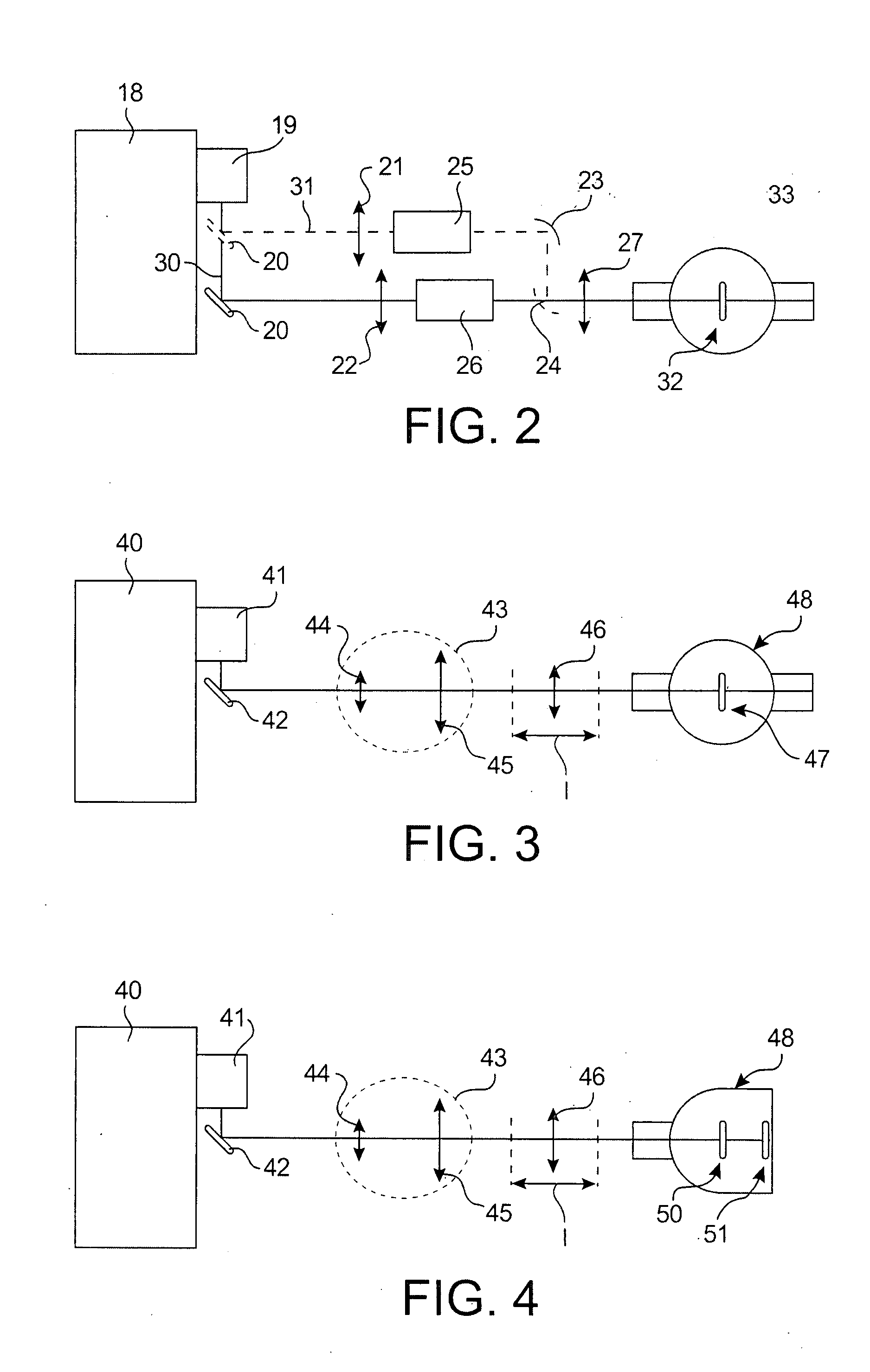

ActiveUS20090014921A1Enhance hourly production rateImprove chemical yieldAuxillary shaping apparatusChemical/physical/physico-chemical processesLight beamContinuous flow

The invention relates to a system for continuous flow production of nanometric or sub-micrometric powders under the action of laser pyrolysis by interaction between a beam emitted by a laser and a flow of reagents emitted by at least one injector, wherein the laser is followed by an optical device allowing the energy of the beam to be distributed along an axis perpendicular to the axis of the flow of reagents, in an elongated cross-section with adjustable dimensions at least at one interaction area between this beam and the flow of reagents emitted by at least two injectors located perpendicularly to the axis of the beam. It also concerns a method for producing such powders.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Abrasive particles for surface polishing

InactiveUS7258706B2Controlling polishing processHigh purityMaterial nanotechnologyPigmenting treatmentCarbideMetallic sulfide

Polishing compositions are described that are appropriate for fine polishing to very low tolerances. The polishing compositions include particles with small diameters with very narrow distributions in size and effectively no particles with diameters several times larger than the average diameter. Furthermore, the particles generally have very high uniformity with respect to having a single crystalline phase. Preferred particles have an average diameter less than about 200 nm. Laser pyrolysis processes are described for the production of the appropriate particles including metal oxides, metal carbides, metal sulfides, SiO2 and SiC.

Owner:NANOGRAM

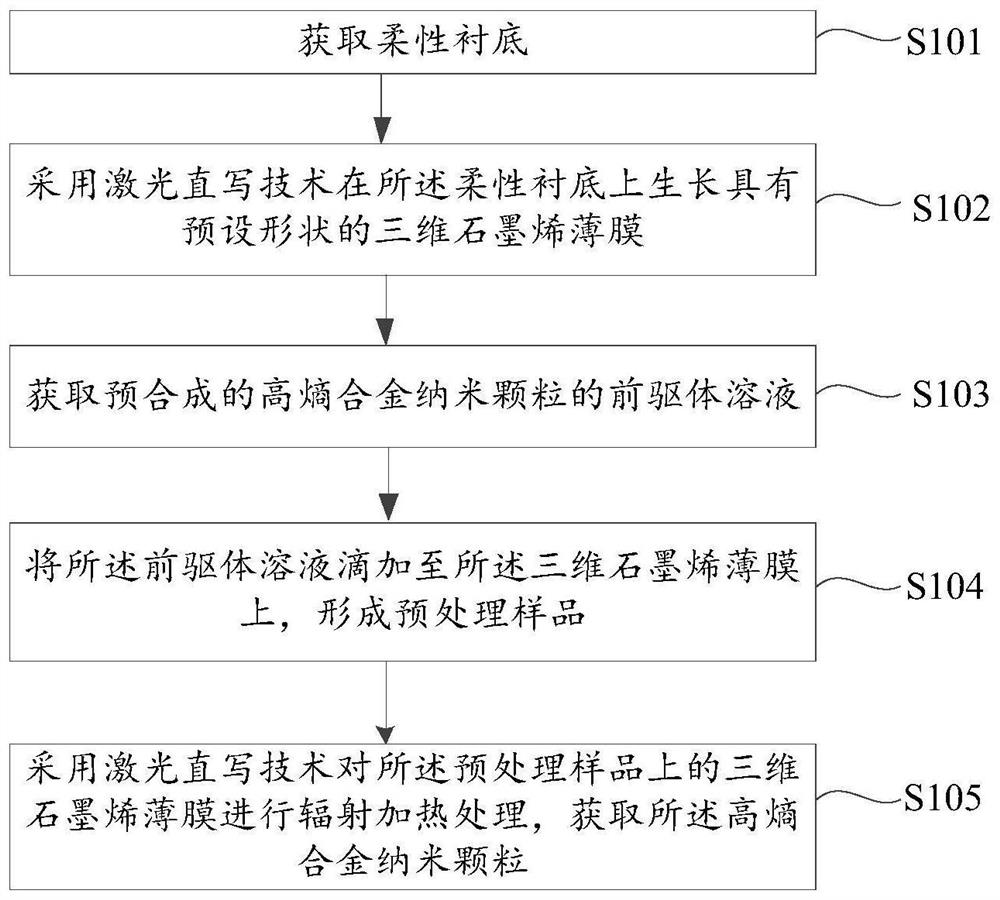

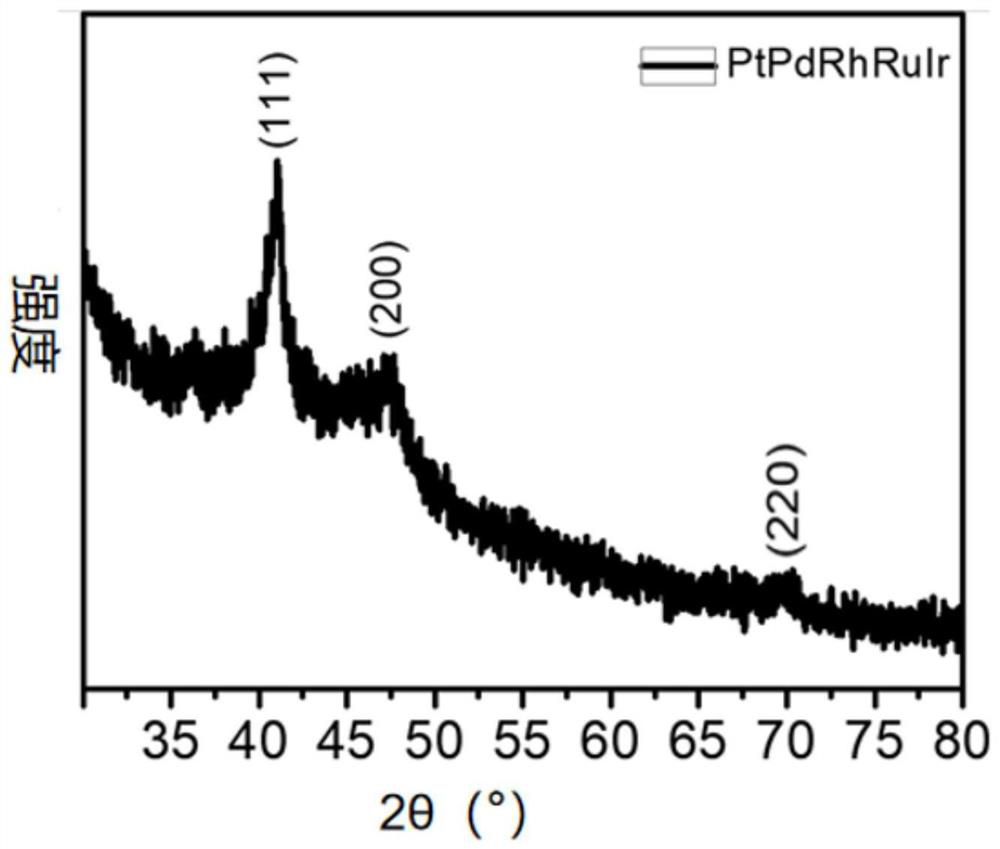

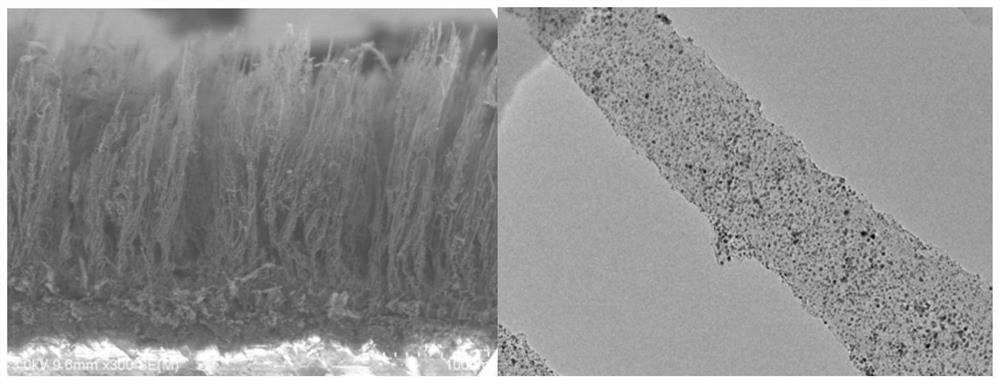

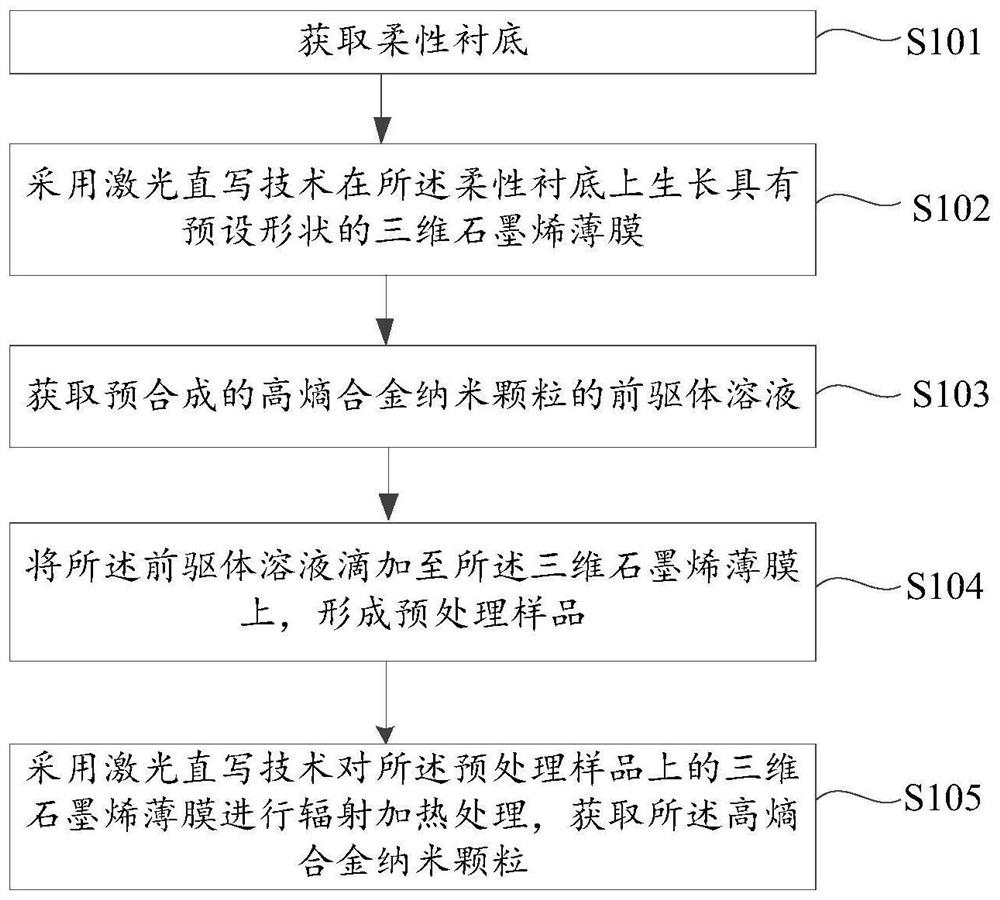

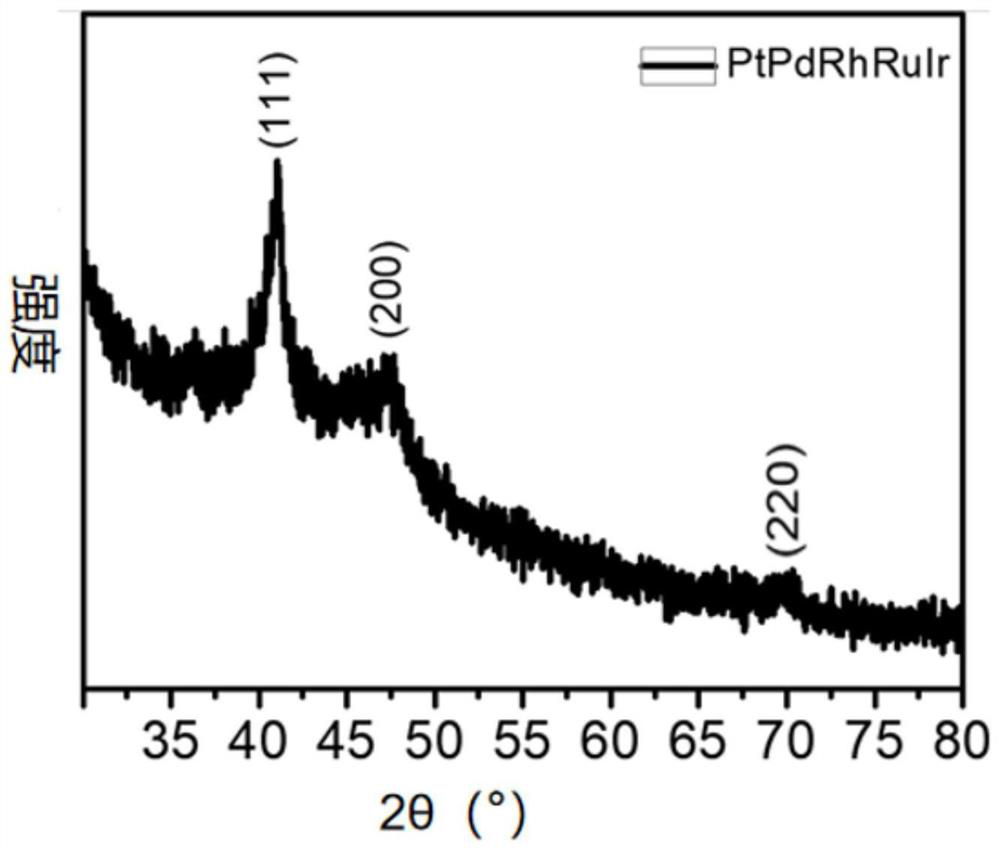

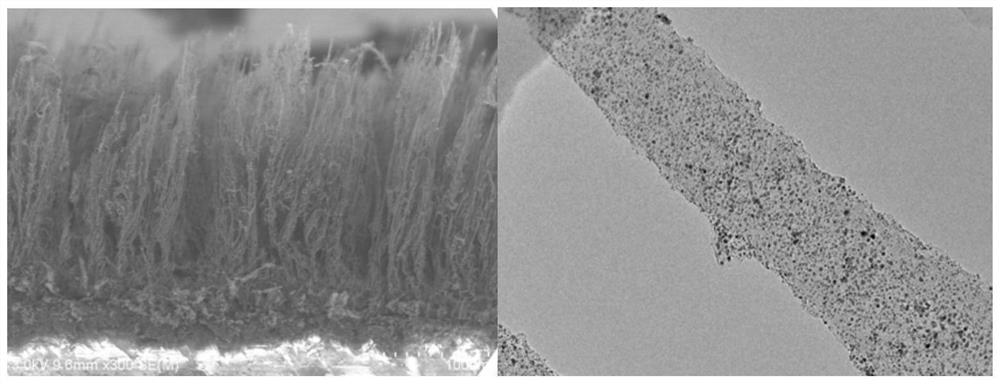

Method for growing high-entropy alloy nanoparticles on flexible substrate

ActiveCN112935274AAvoid high temperature heat damageAchieve growthMaterial nanotechnologyTransportation and packagingHigh entropy alloysThin membrane

The invention provides a method for growing high-entropy alloy nanoparticles on a flexible substrate. The method comprises the steps that the flexible substrate is obtained; a three-dimensional graphene film with a preset shape is grown on the flexible substrate by adopting a laser direct writing technology; a precursor solution of the high-entropy alloy nanoparticles is obtained; the precursor solution is dropwise added onto the three-dimensional graphene film to form a pretreated sample; and radiation heating treatment is performed on the three-dimensional graphene film on the pretreated sample by adopting the laser direct writing technology to obtain the high-entropy alloy nanoparticles. Based on the technical scheme, the uniformity of the size of the high-entropy alloy nanoparticles and the total loading capacity of the alloy can be effectively improved; high-temperature thermal damage to the flexible substrate is effectively avoided; and meanwhile, a pulse laser pyrolysis growth mechanism is also conducive to obtaining the high-entropy alloy nanoparticles with a single phase.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

System and method for continuous flow production of nanometric or sub-micrometric powders by the action of laser pyrolysis

ActiveUS9005511B2Improve productivityLoss of power densityAuxillary shaping apparatusEnergy based chemical/physical/physico-chemical processesLight beamContinuous flow

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

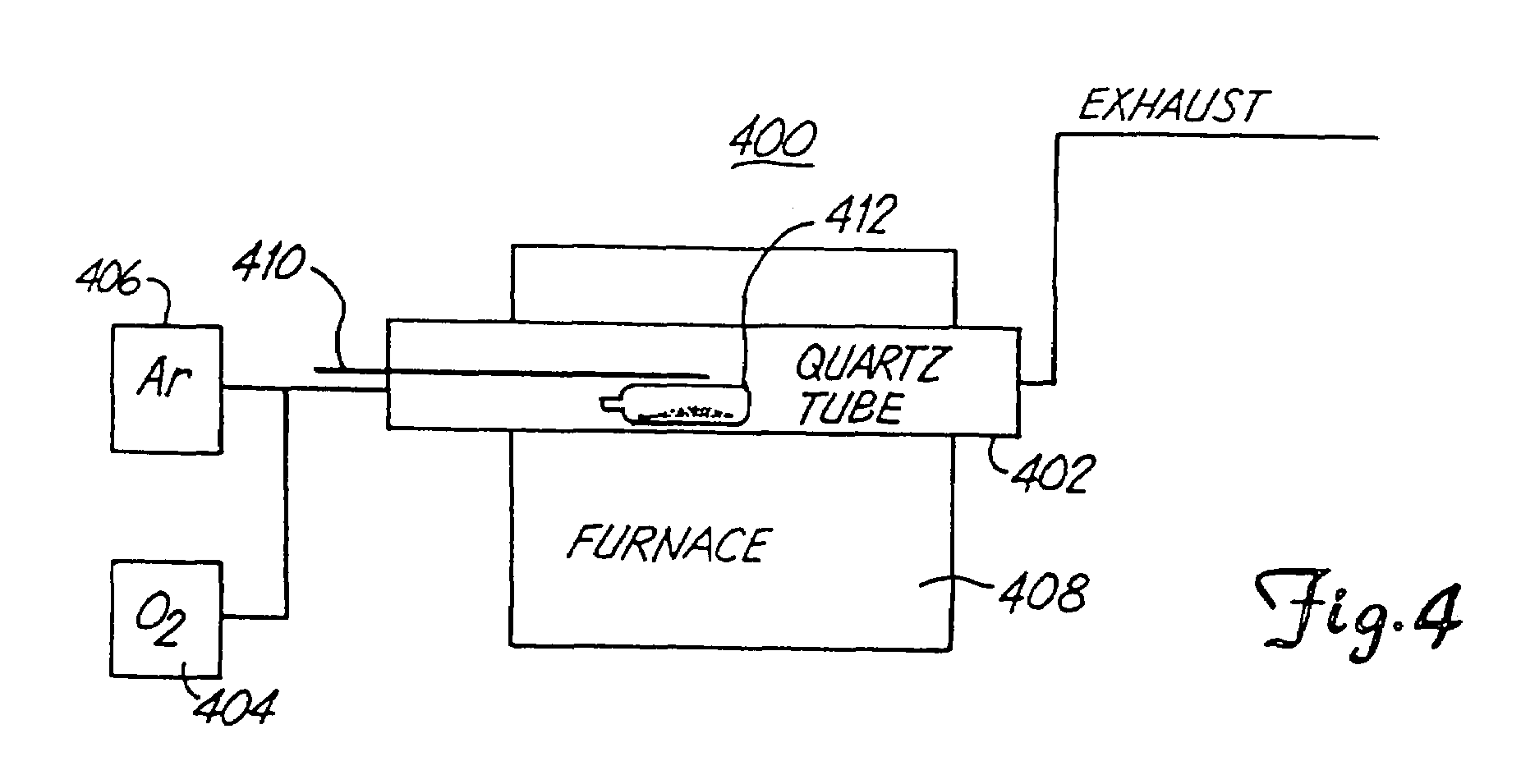

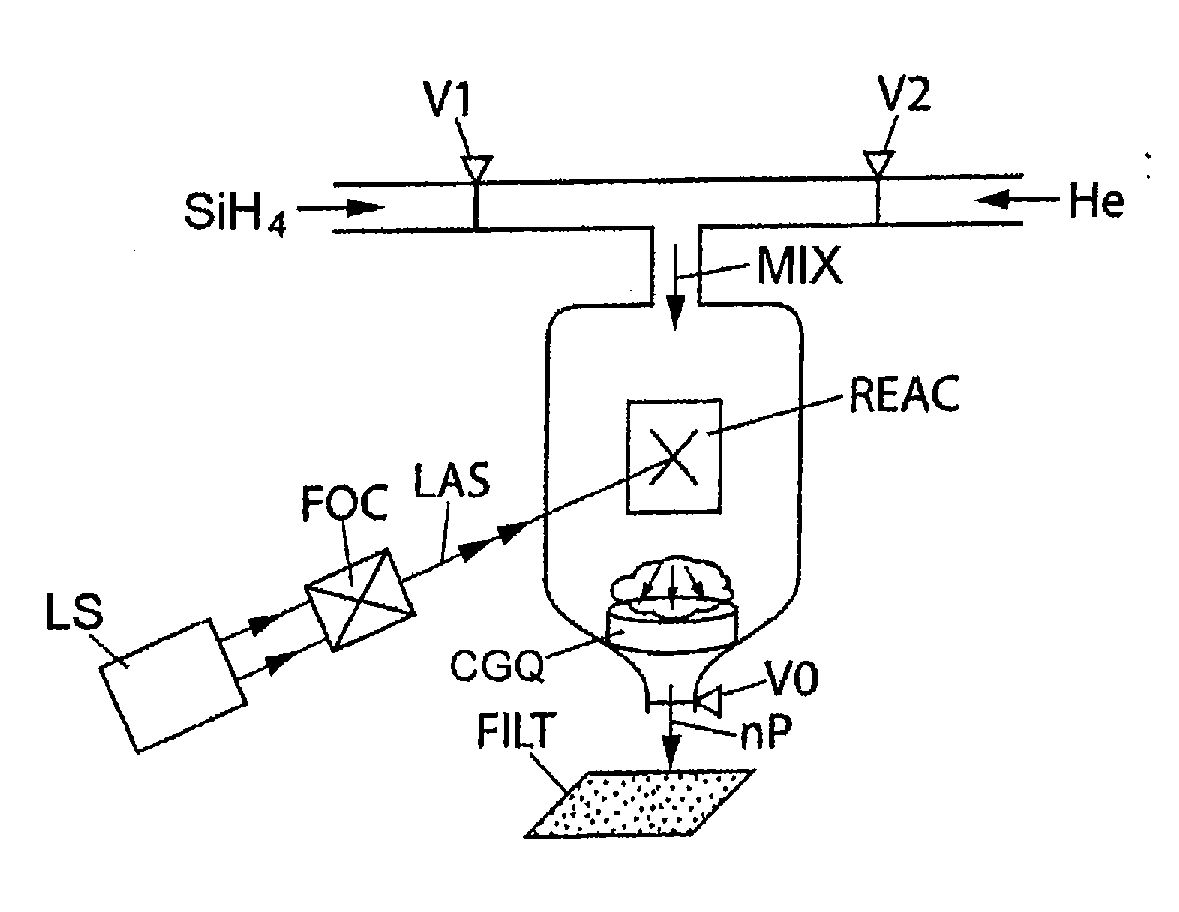

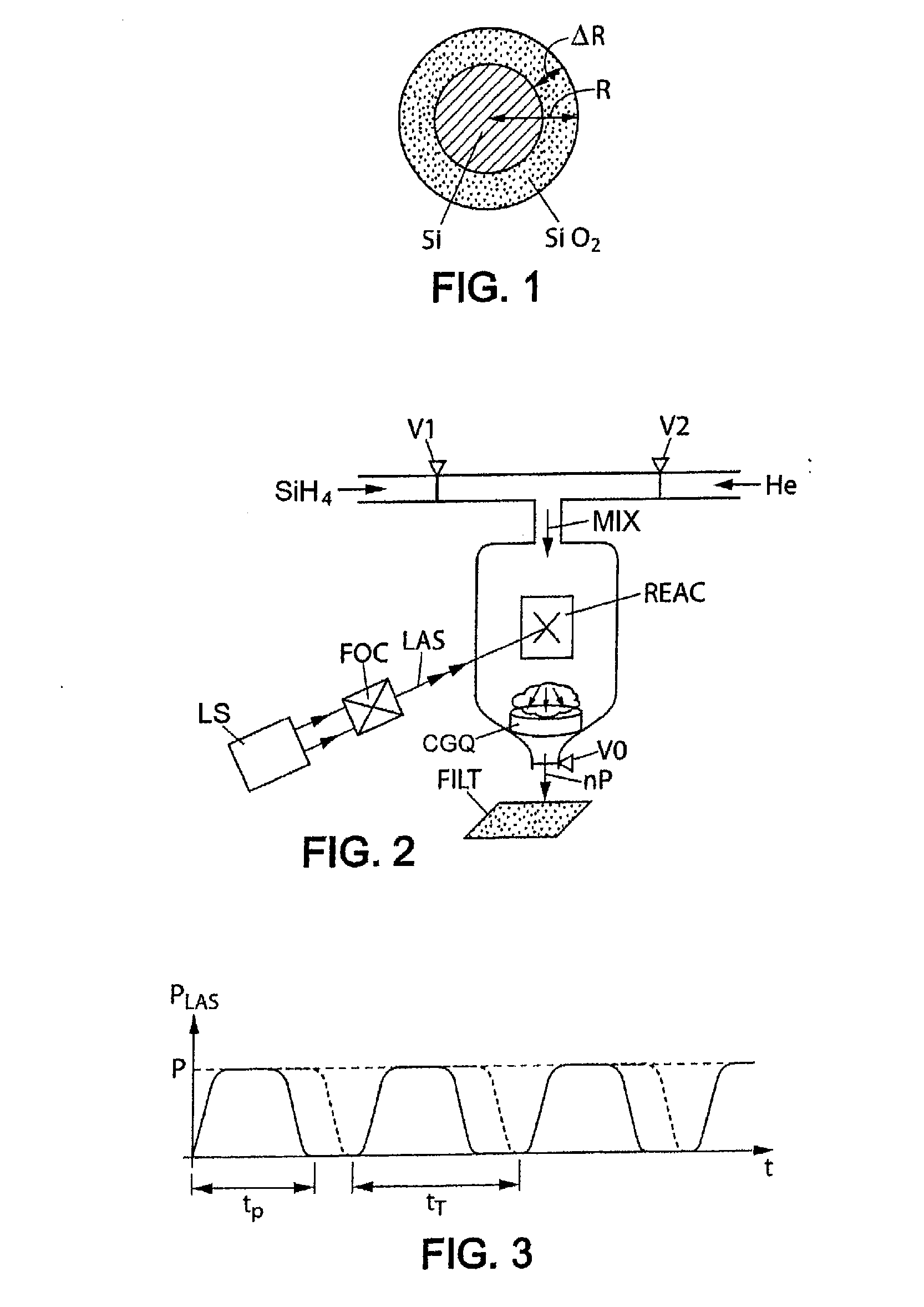

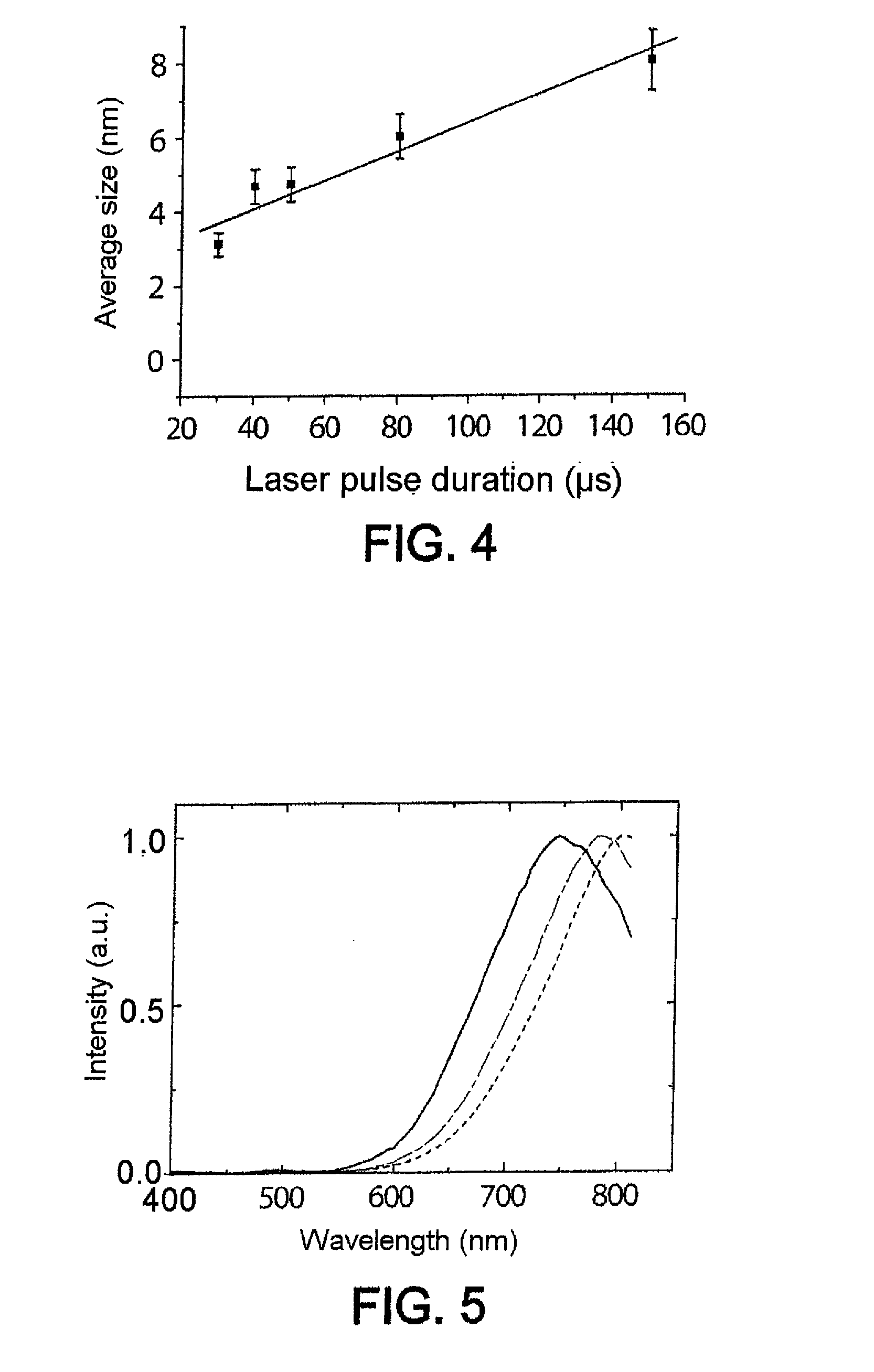

Synthesis of silicon nanocrystals by laser pyrolysis

ActiveUS8337673B2Improve productivityIncrease ratingsMaterial nanotechnologyEnergy based chemical/physical/physico-chemical processesSilicon nanocrystalsCrystal structure

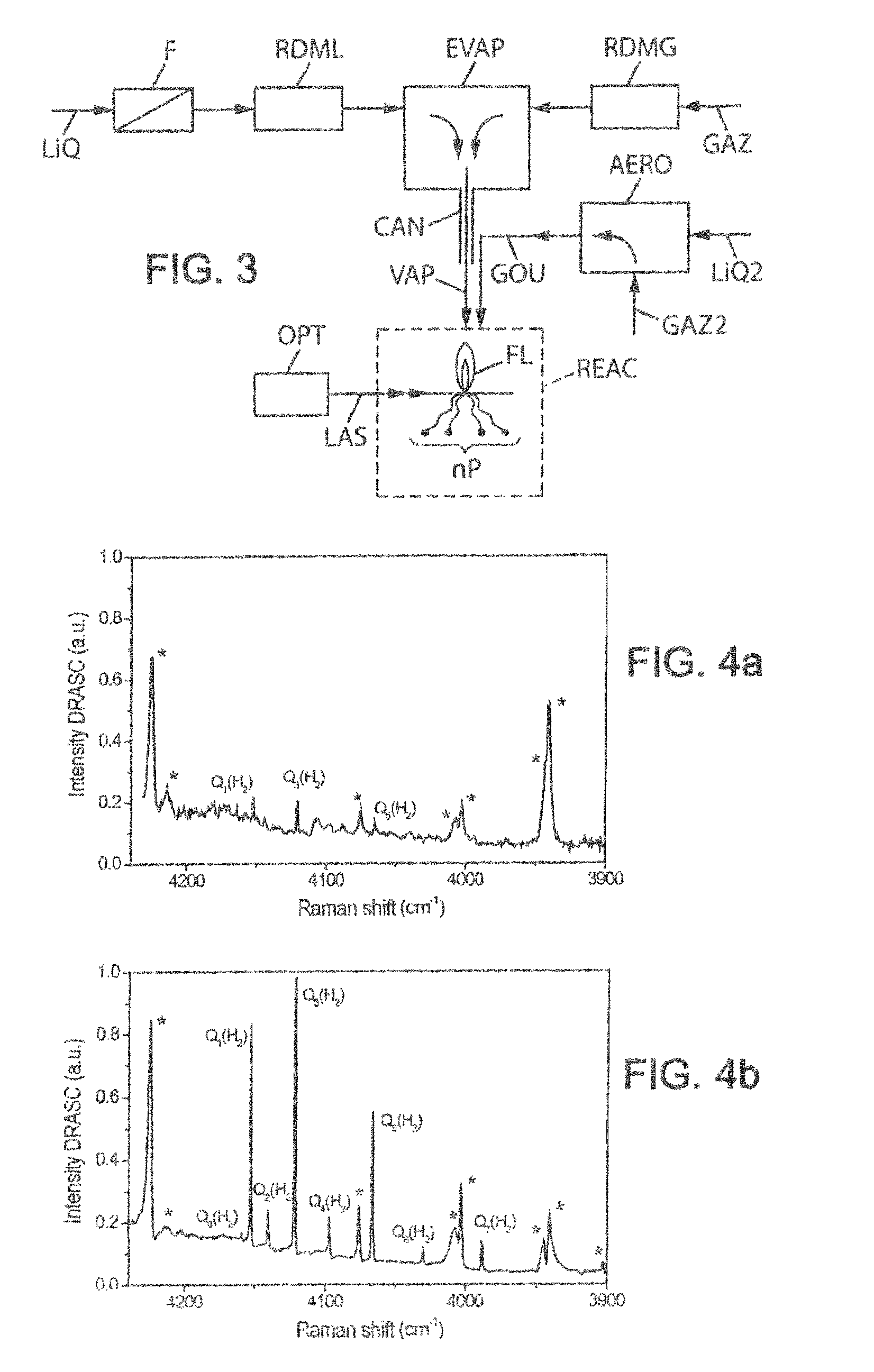

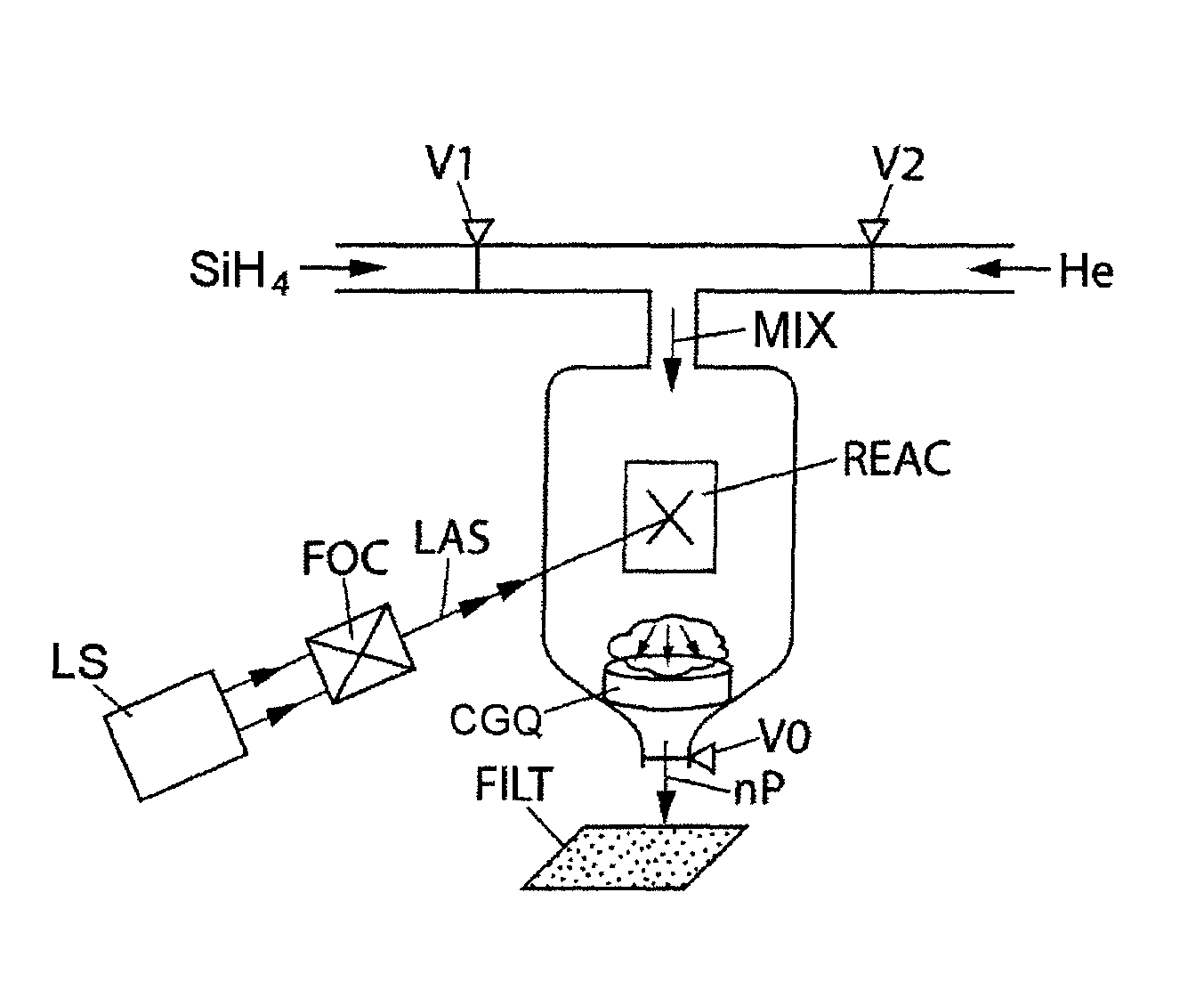

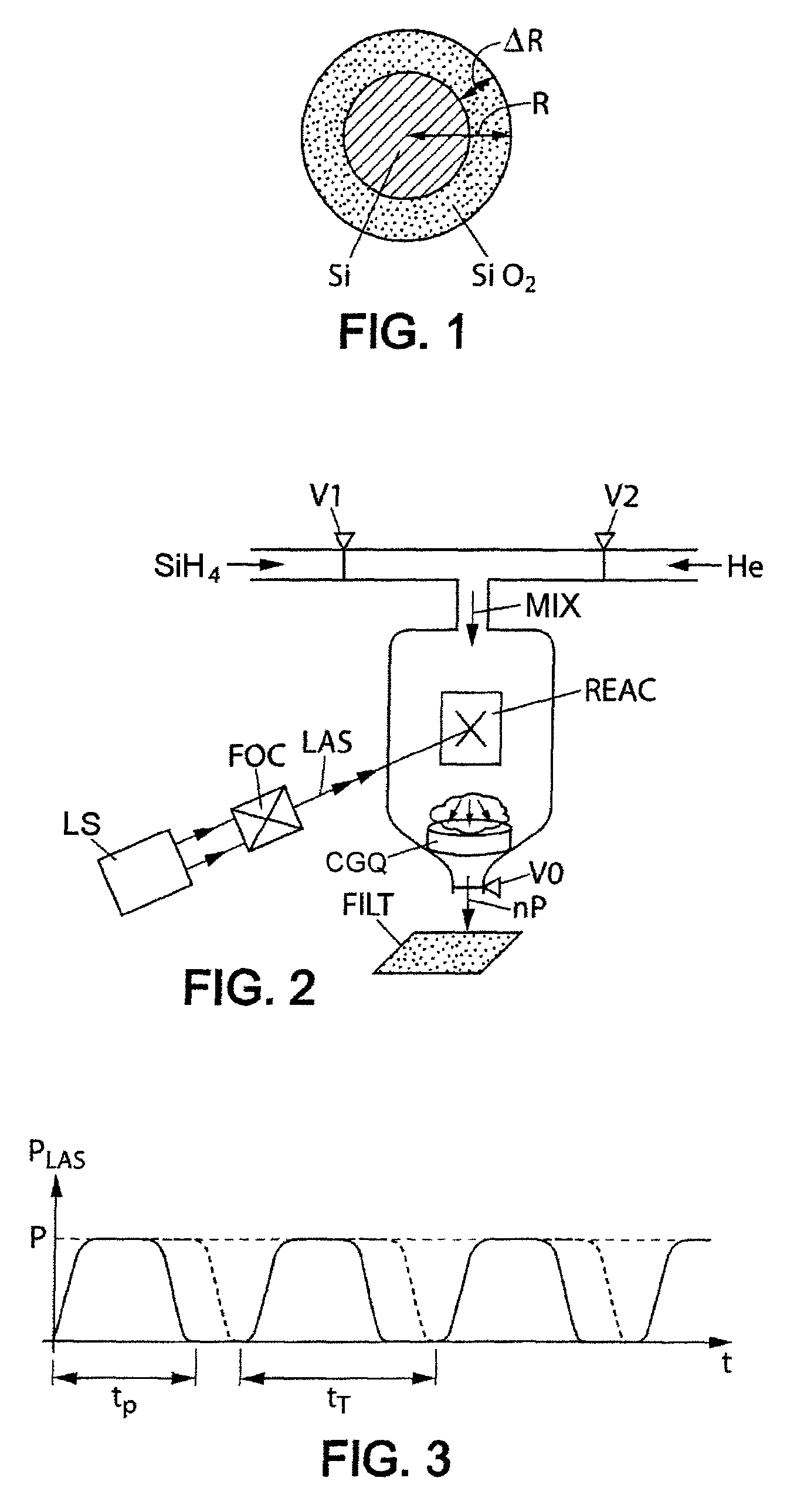

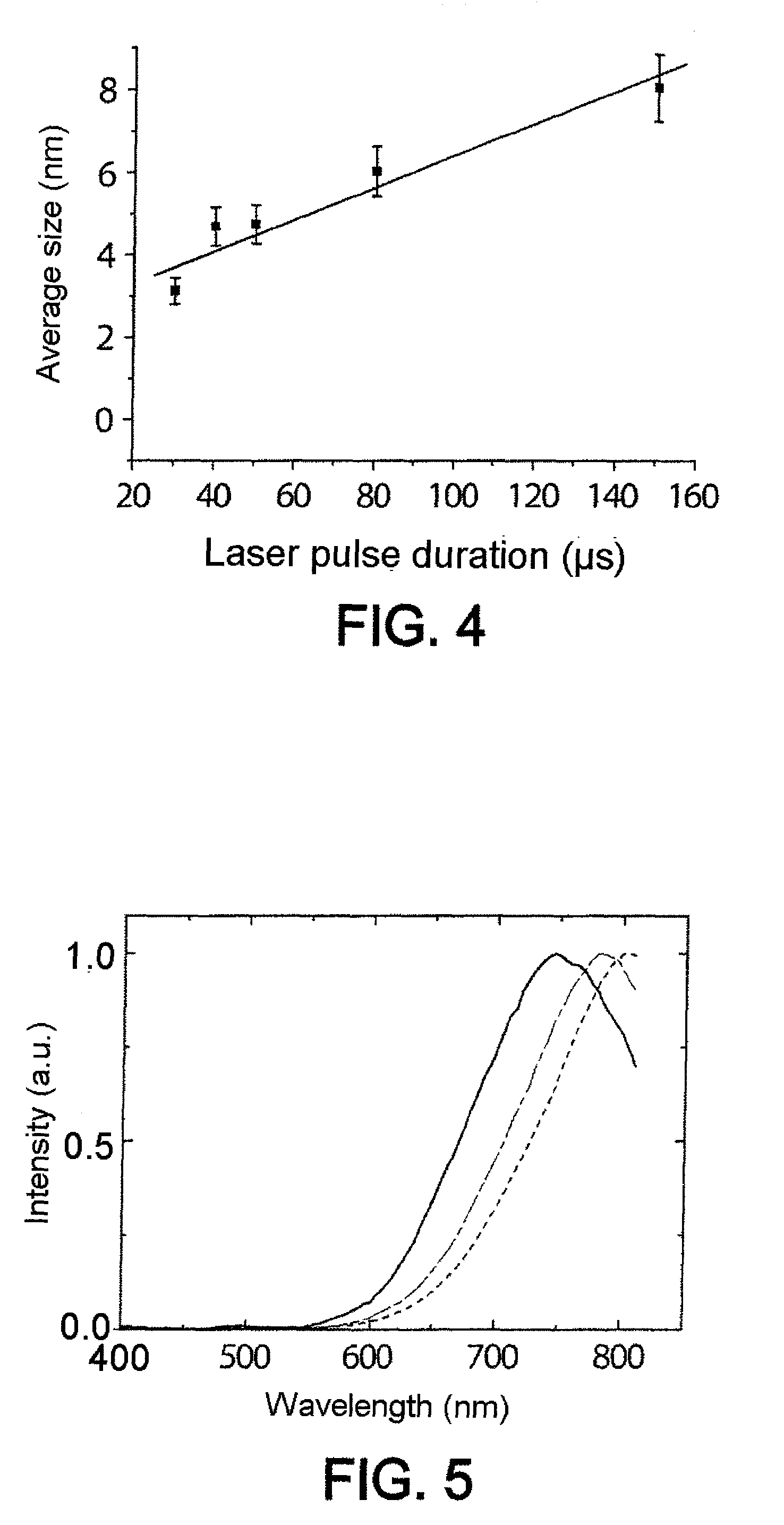

The invention relates to the synthesis of silicon-containing nanoparticles by laser pyrolysis. For this purpose: a precursor (SiH4) containing the element silicon is conveyed, by a transport fluid (He), into a pyrolysis reactor (REAC); laser radiation (LAS) is applied, in the reactor, to a mixture that the transport fluid and the precursor form; and silicon-containing nanoparticles (nP) are recovered at the exit of the reactor. In particular, the power of the laser radiation is controlled. Furthermore, the effective pulse duration is controlled within a laser firing period. Typically, for a power greater than 500 watts and a pulse duration greater than 40% of a laser firing period, nanoparticles having a crystalline structure with a size of less than or of the order of one nanometer are obtained at a rate greater than or of the order of 80 milligrams per hour. Under optimum conditions, a record rate of greater than 740 milligrams per hour was able to be obtained.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

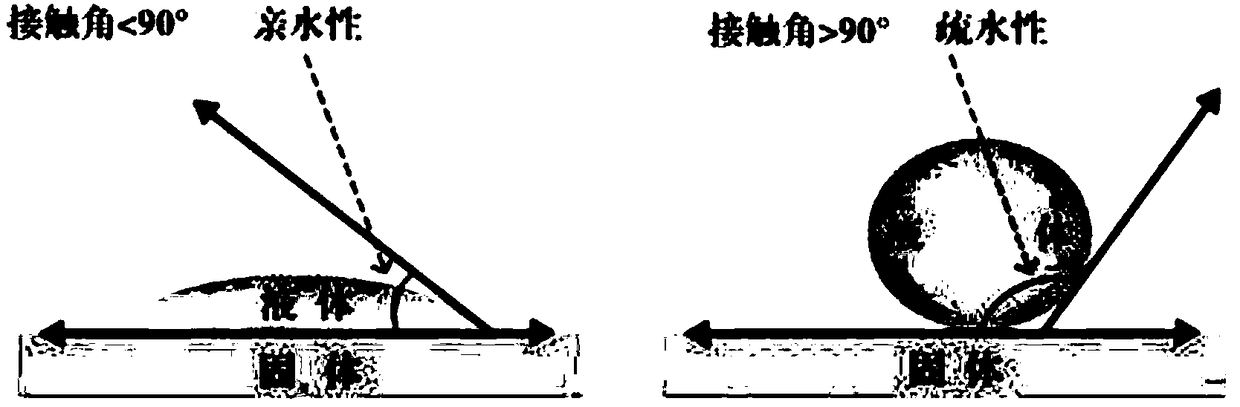

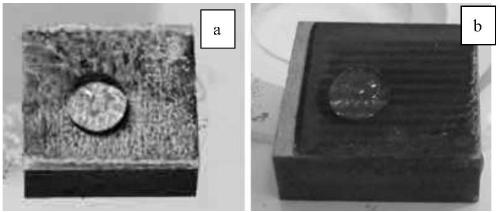

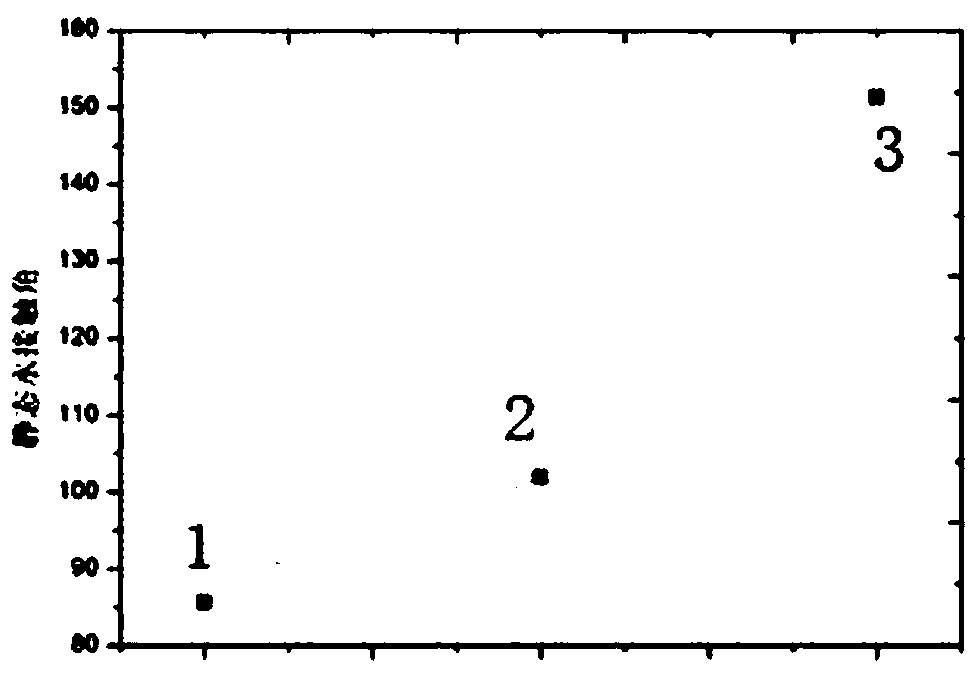

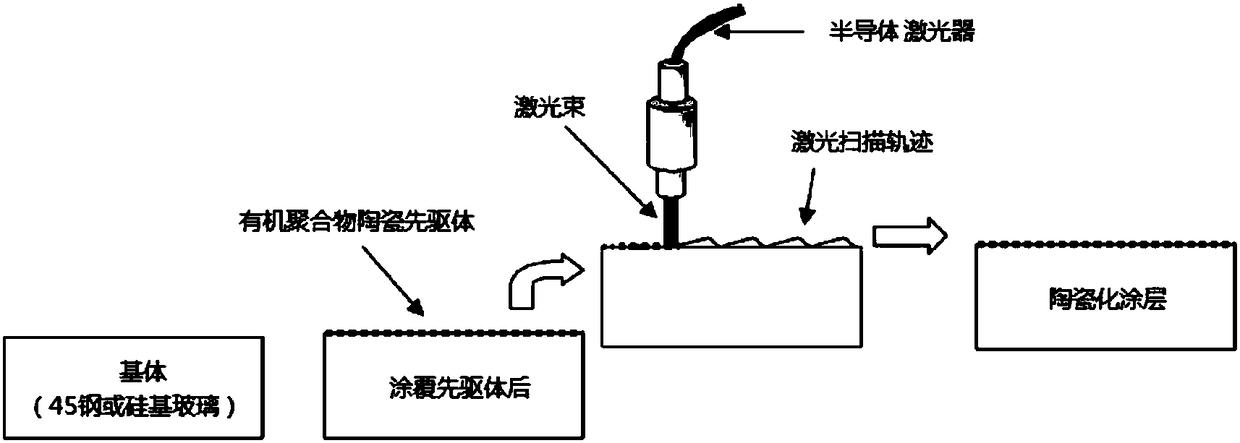

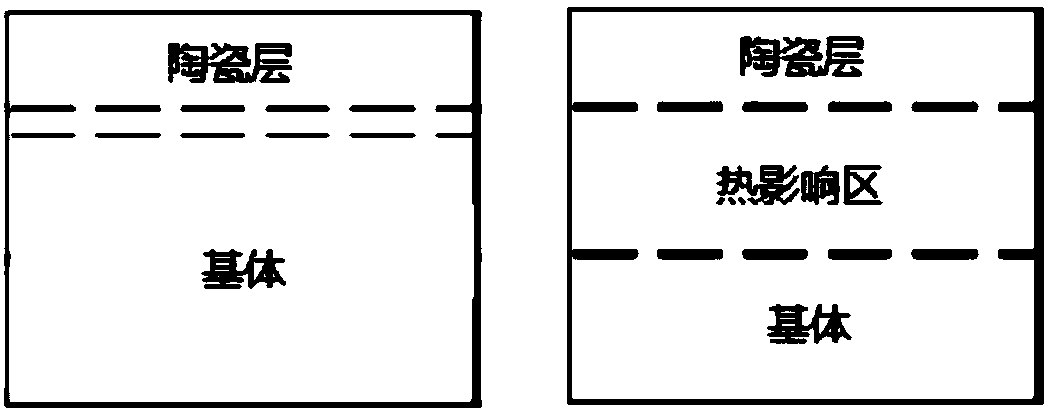

Superhydrophobic ceramic coating and preparation method thereof

ActiveCN109402615ASuperhydrophobicity hasImprove service performanceSolid/suspension decomposition chemical coatingHeat-affected zoneCeramic coating

The invention provides a superhydrophobic ceramic coating and a preparation method thereof. The superhydrophobic ceramic coating is prepared through the steps that a substrate is pretreated, and the substrate is coated or sprayed with a mixture of a polysilazane organic polymer ceramic precursor and filler, wherein the filler is ferrocene or tetrabutyl titanate; under the protection of inert gas,a coating layer is subjected to laser scanning, ceramic conversion is achieved, and the ceramic coating is obtained. According to the method, compared with a traditional high temperature sintering method, sintering is not needed, and energy consumption is reduced; laser energy is concentrated, the heat affected zone is small, the substrate phase composition is not affected, the problem that when the ceramic coating is prepared through the single polysilazane organic polymer ceramic precursor, due to the fact that laser pyrolysis micromolecules overflow, the coating surface has cracks and air holes can be effectively solved, and the obtained ceramic coating has the high hardness and corrosion resistance and the excellent super-hydrophobicity.

Owner:ARMOR ACADEMY OF CHINESE PEOPLES LIBERATION ARMY

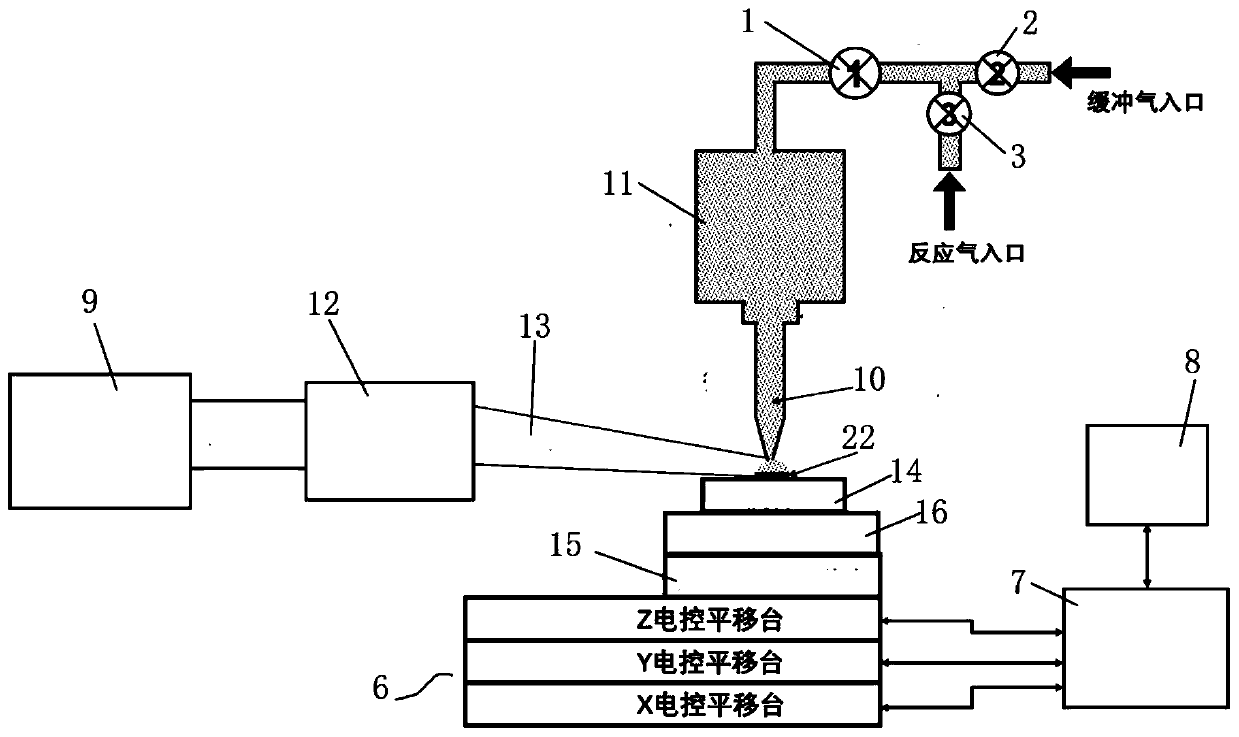

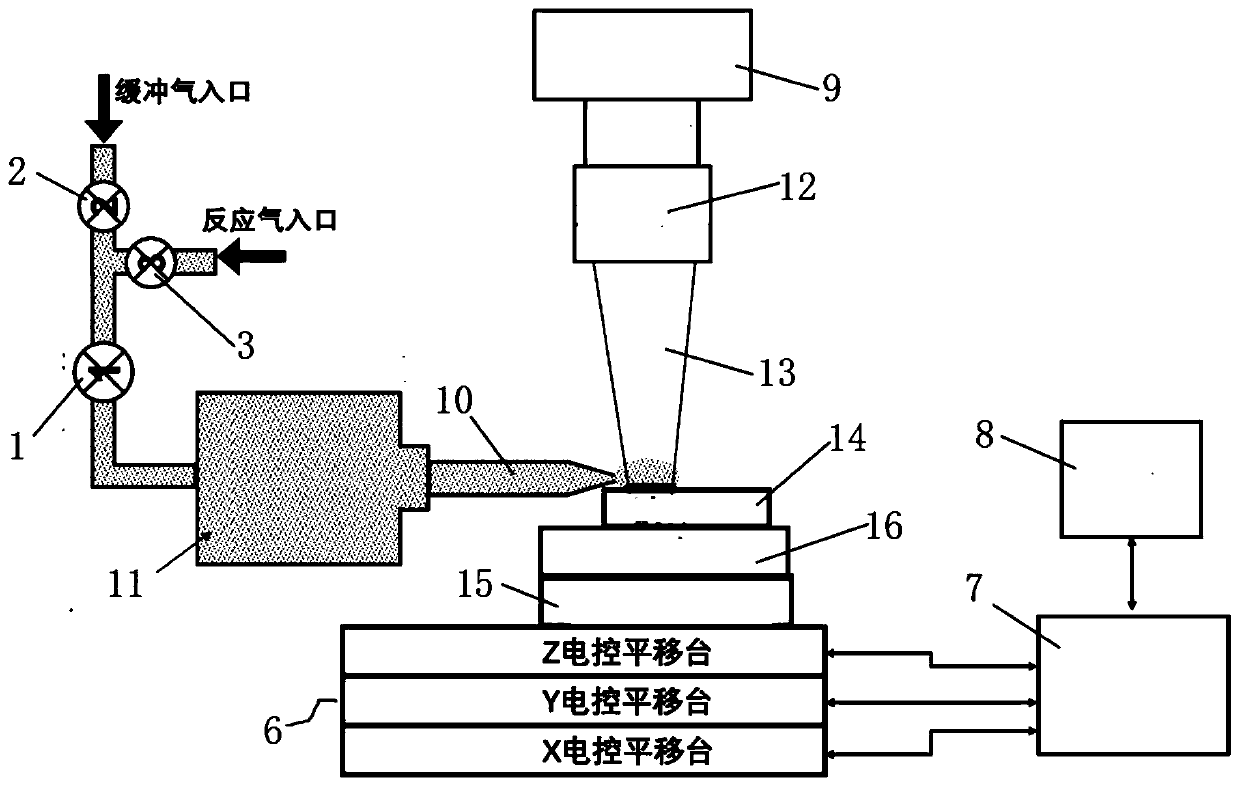

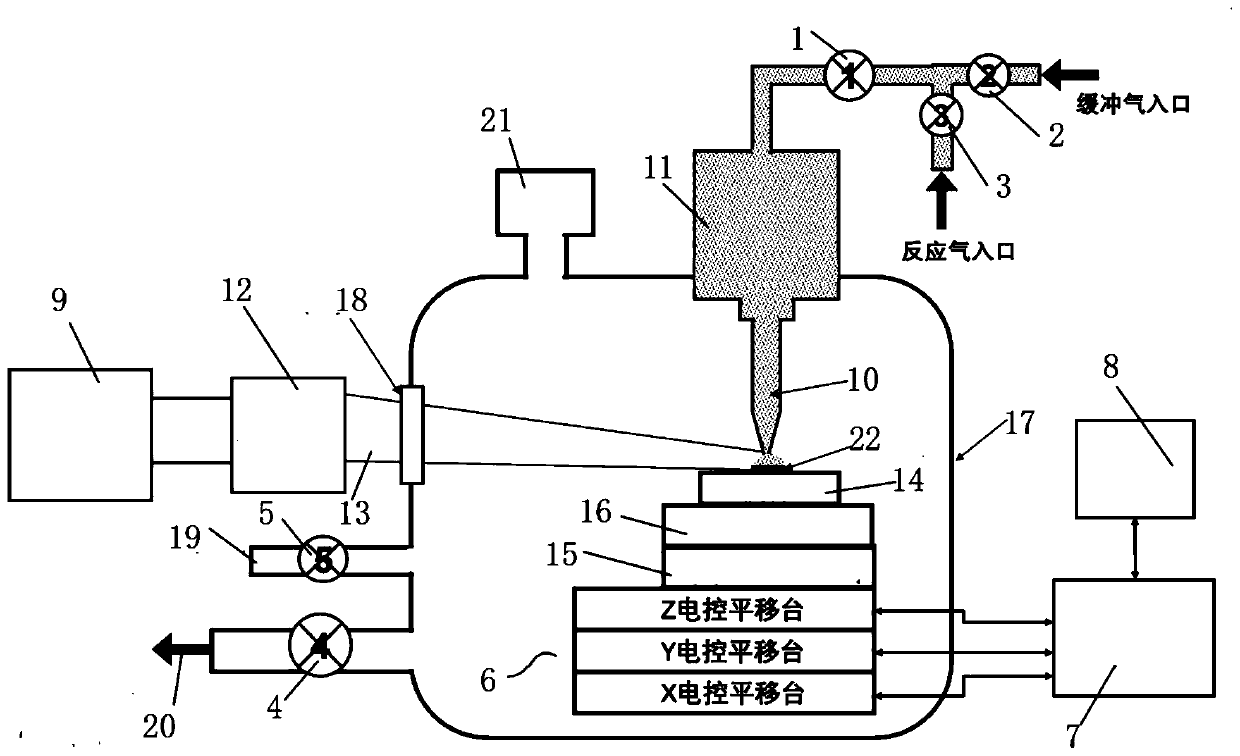

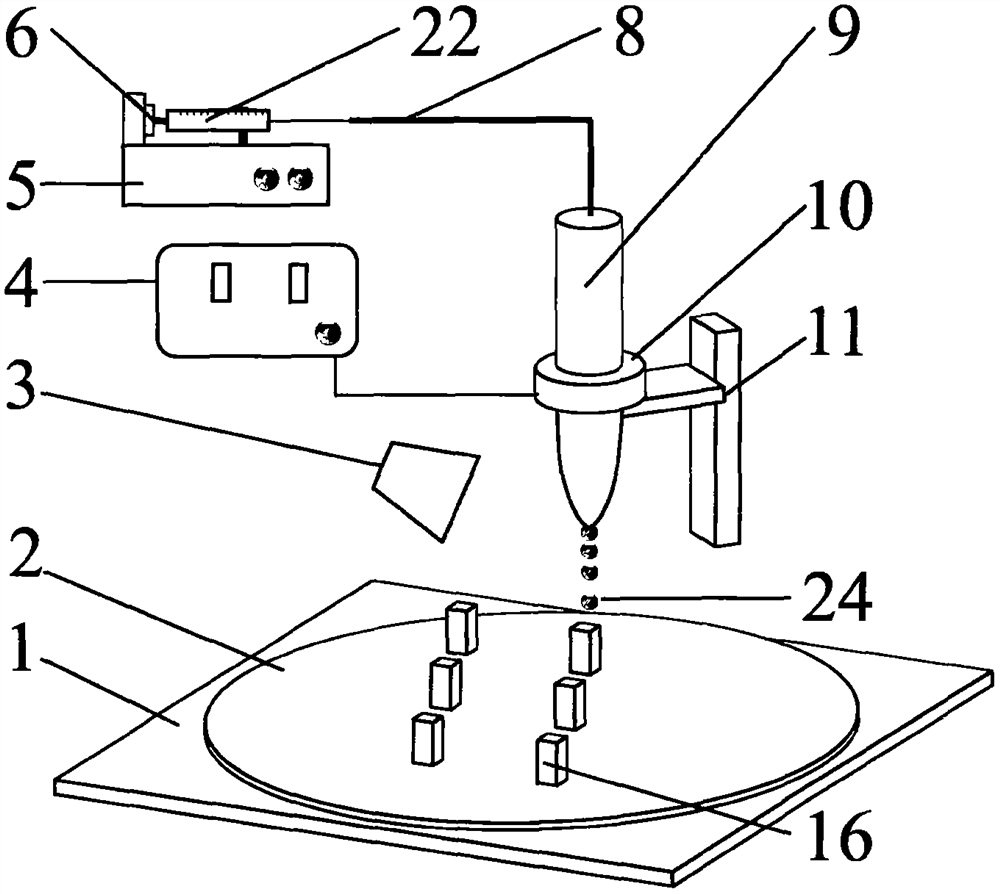

Micro-nano three-dimensional printing method and device based on laser chemical vapor deposition

ActiveCN110512193ADiffusion is weakImprove printing accuracyAdditive manufacturing apparatusChemical vapor deposition coatingMicron scaleMicro nano

The invention provides a micro-nano three-dimensional printing method based on laser chemical vapor deposition; and the laser chemical deposition is combined with a localized gas injection technologybased on a micropipe to realize micro-nano 3D printing of wide material systems and to improve the printing precision. Laser beams emitted by a laser are collected to microareas to be processed on thesurfaces of samples after passing through an optical element set; reaction gas and buffer gas are mixed and injected in a gas cavity; the gas cavity communicates with the micropipe by an adapter; themixed gas of the reaction gas and the buffer gas is injected to the microareas to be processed on the surfaces of the samples by the tip end of the micropipe, and is radiated by the collected laser beams; under the laser pyrolysis effect and / or the photolysis effect, the reaction gas is dissociated, and the decomposed products are deposited on the surfaces of the products to form plating layers;the inner diameter of the tip end of the micropipe is nanometer or micron-scale; and according to preset patterns, an electric control translation platform is adjusted to move in a coordinated mode torealize three-dimensional relative movement of the micropipe and the surfaces of the samples so as to generate three-dimensional micro-nano patterns.

Owner:橙河微系统科技(上海)有限公司

Production of nanometric or sub-micrometric powders in continuous flux

ActiveUS8822878B2High temperature gas-gas reactionChemical/physical/physico-chemical processesLaser pyrolysisMolecular physics

A system and process for production of nanometric or sub-micrometric powders in continuous flux under the action of laser pyrolysis in at least one interaction zone between a beam emitted by a laser and a flux of reagents emitted by an injector, in which the laser is followed by optical means for distributing the energy of the beam emitted by the latter according to an axis perpendicular to the axis of each flux of reagents, in an elongated cross-section having adjustable dimensions at the level of this at least one interaction zone.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

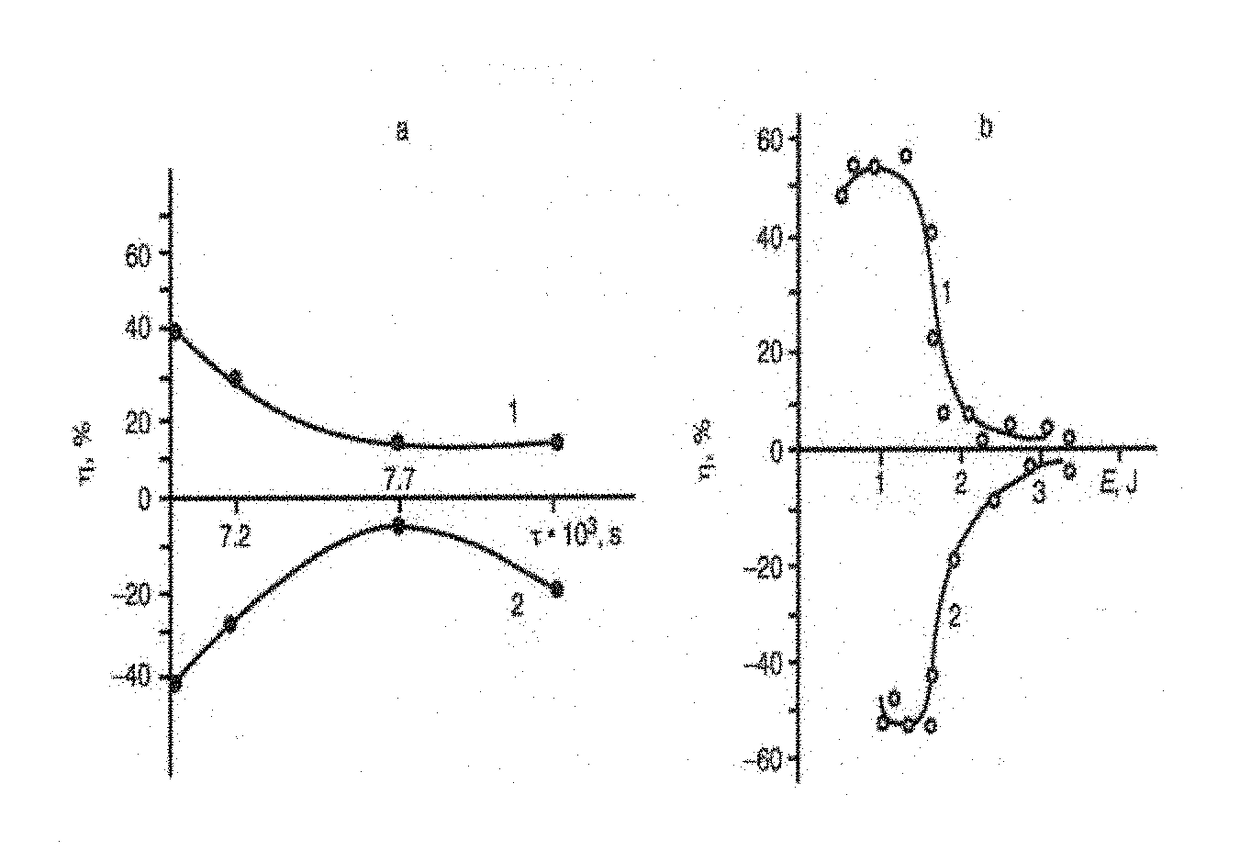

Shock wave nano-technology method

InactiveUS20180324937A1Increase arc lengthImprove heating efficiencyMaterial nanotechnologyMolten spray coatingShock waveChemical reaction

The patent described the advantages of detonation plasma spraying, laser pyrolysis technologies, etc., being optimized by pulses with common parameters, like duration, slope for all mentioned above technologies.For example, in some high temperature processes, using pulsed plasma or laser technology, plays vital important role the efficiency of plasma chemical processes. Since the plasma chemical reaction process efficiency is ˜20-30%, its value could be increased up to the thermodynamically feasible level of 60%.The Shock waves created by electrical pulses disintegrates liquid particles up to Nano size fragments, accelerate them and finally formatted a coating with superior characteristics.The influence of the pulses of radiation, detonation, electro impulse plasma can be generated by the same single pulse parameters of duration, slope, etc.

Owner:GUTMAN BARUCH BORIS

Tin oxide particles

InactiveCN1292750AMaterial nanotechnologyPolycrystalline material growthDisplay deviceOxidation state

Tin oxide nanoparticles were produced with tin in a variety of oxidation states. In particular, nanoparticles of single phase, crystalline SnO2 were produced. Preferred tin oxide nanoparticles have an average diameter from about 5 nm to about 100 nm with an extremely narrow distribution of particle diameters. The tin oxide nanoparticles can be produced in significant quantities using a laser pyrolysis apparatus. Nanoparticles produced by laser pyrolysis can be subjected to further processing to change the properties of the particles without destroying the nanoscale size of the particles. The nanoscale tin oxide particles are useful for the production of transparent electrodes for use in flat panel displays.

Owner:NANOGRAM

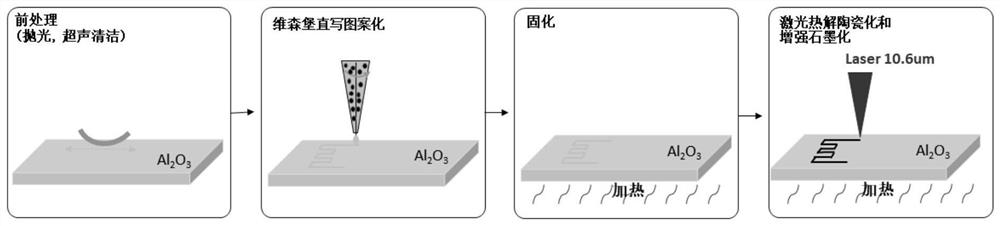

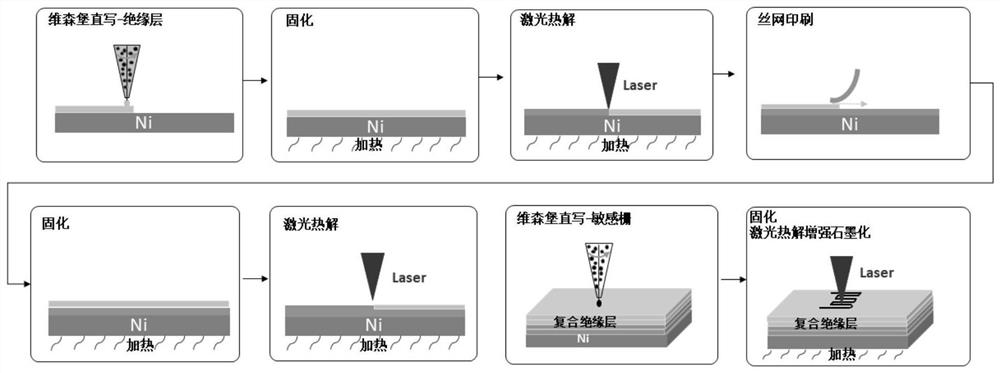

Laser pyrolysis composite additive manufacturing integrated precursor ceramic film sensor and preparation method thereof

PendingCN114322741AReduce the impactEasy to changeAdditive manufacturing apparatusForce measurementMetallic materialsThin membrane

The invention discloses a laser pyrolysis composite additive manufacturing integrated precursor ceramic film sensor and a preparation method thereof, a metal component or an insulating material is used as a substrate, and a PDC doped composite insulating film layer with high compactness, high insulativity and high temperature resistance is formed on the surface of the metal component through a layer-by-layer laser pyrolysis additive technology; a sensitive grid of PDC doped filler is directly written on the composite insulating film layer through Vensengburg, and a strain sensitive layer with excellent conductivity is obtained through a method for enhancing PDC graphitization through laser pyrolysis, so that laser in-situ additive integrated manufacturing of the high insulating film layer based on the PDC material, the sensitive grid with excellent conductivity and the metal substrate is created; the laser technological process of liquid-solid-function conversion of the PDC composite material is achieved, and the PDC composite material is successfully applied to metal material strain sensing.

Owner:XIAMEN UNIV

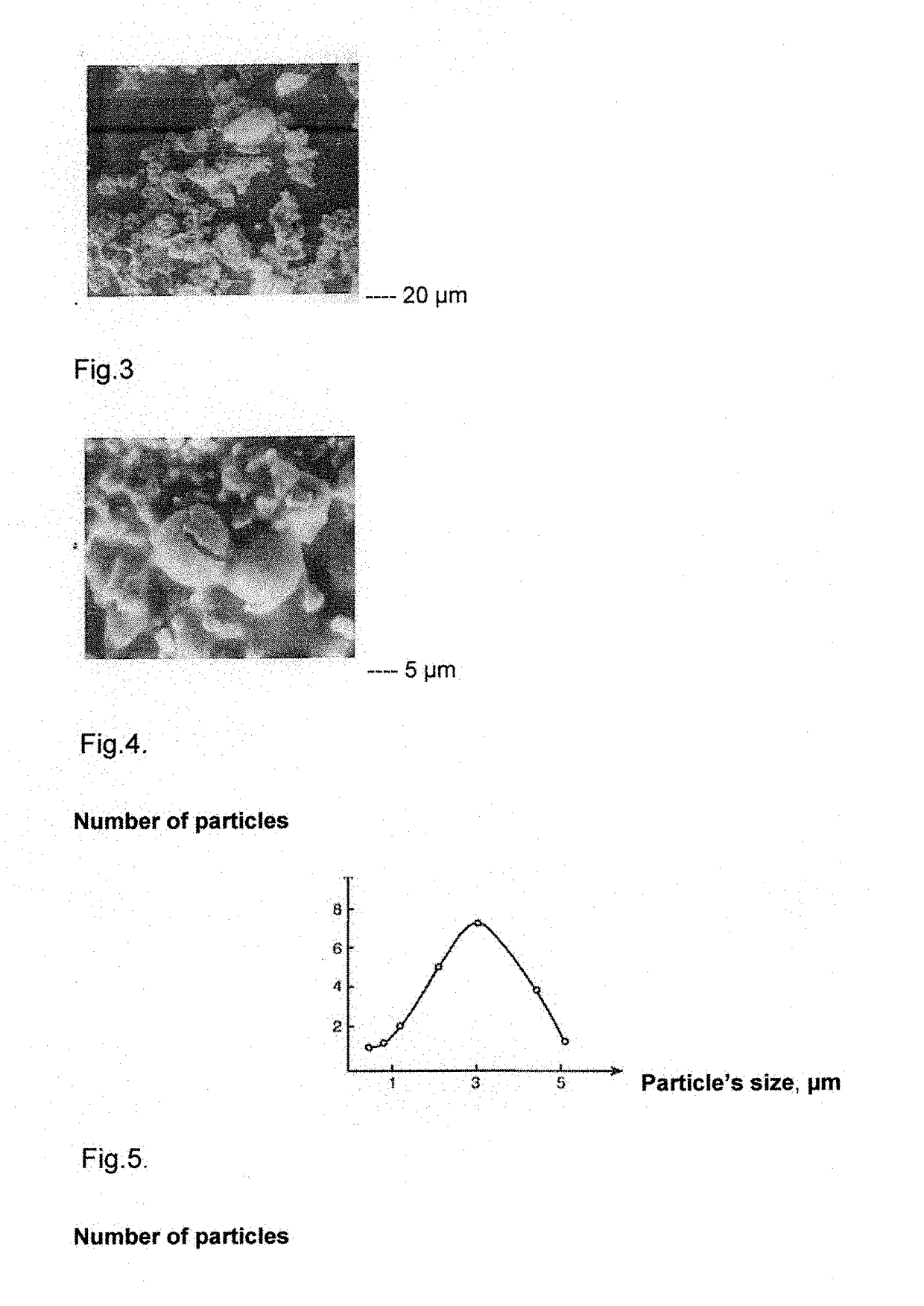

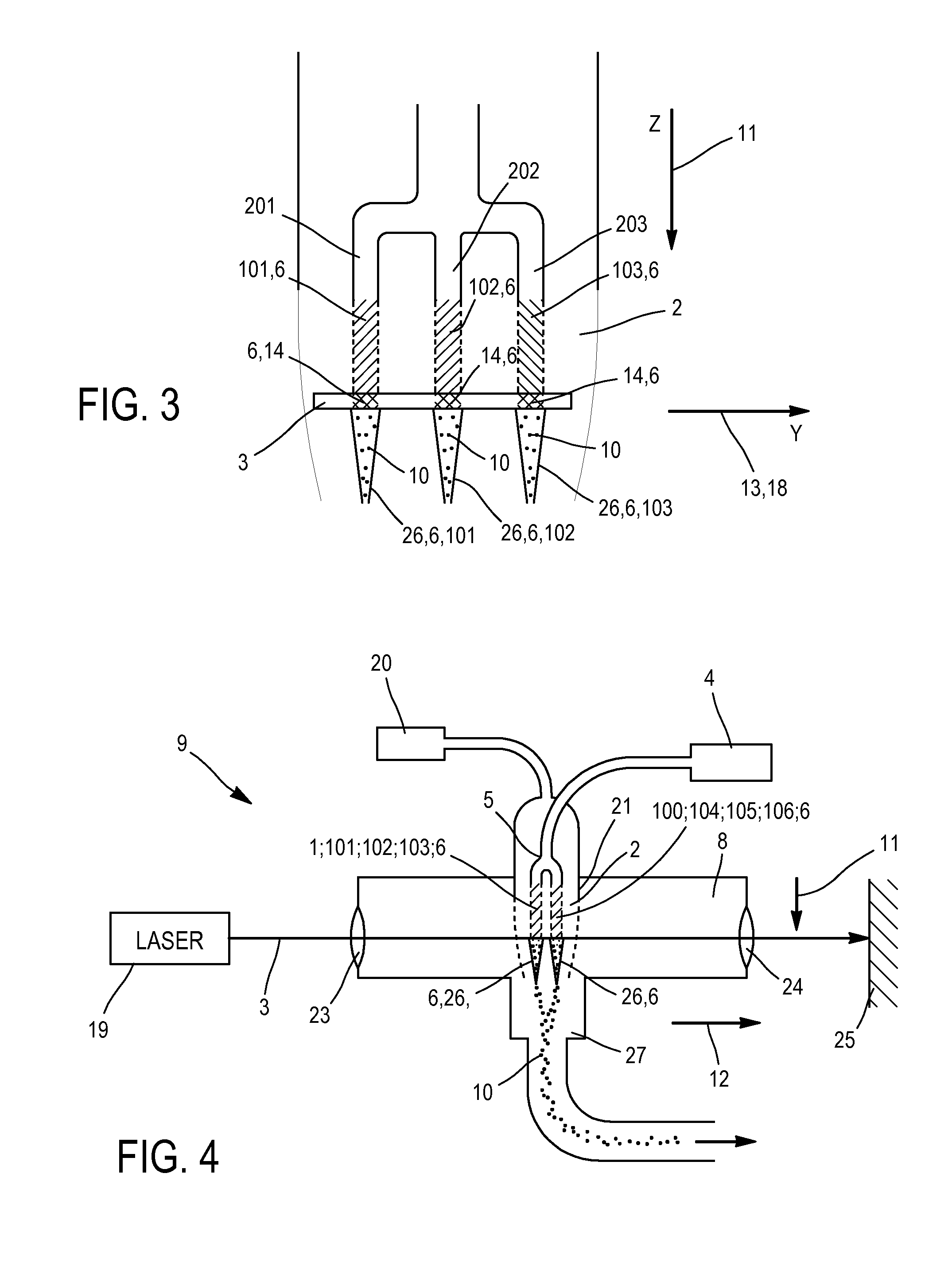

Method for producing multilayer submicron particles by laser pyrolysis

ActiveUS20150151976A1Prevent oxidationInhibitionMaterial nanotechnologyElectric discharge heatingChemical elementUnit of time

Disclosed is a method for producing particles, including the steps: introducing, into a reaction chamber, at least one reaction flow including a first chemical element and propagating in a direction of flow; projecting a radiation beam through the reaction chamber, intersecting each reaction stream in one interaction area per reaction flow, to form, in each reaction flow, particle cores including the first chemical element; and introducing, into the reaction chamber, a second chemical element interacting with each reaction flow to cover the particle cores with a layer including the second chemical element. Each reaction flow is preferably free of any agent oxidizing the first chemical element. Preferably a ratio of one atom of the second element is introduced per unit of time for at least two atoms of the first element introduced per unit of time. The second element is preferably introduced in at least one confined flow.

Owner:NANOMAKERS

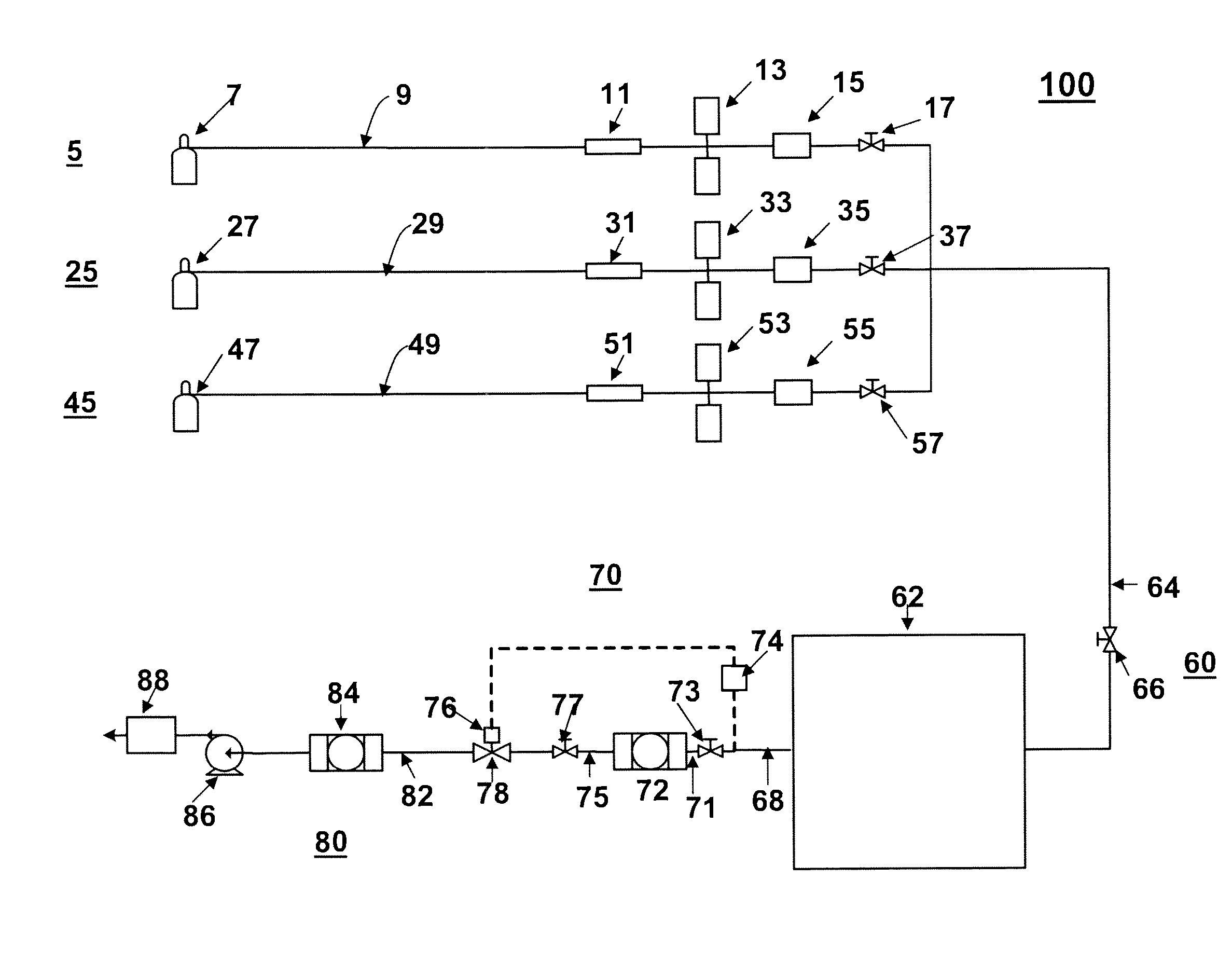

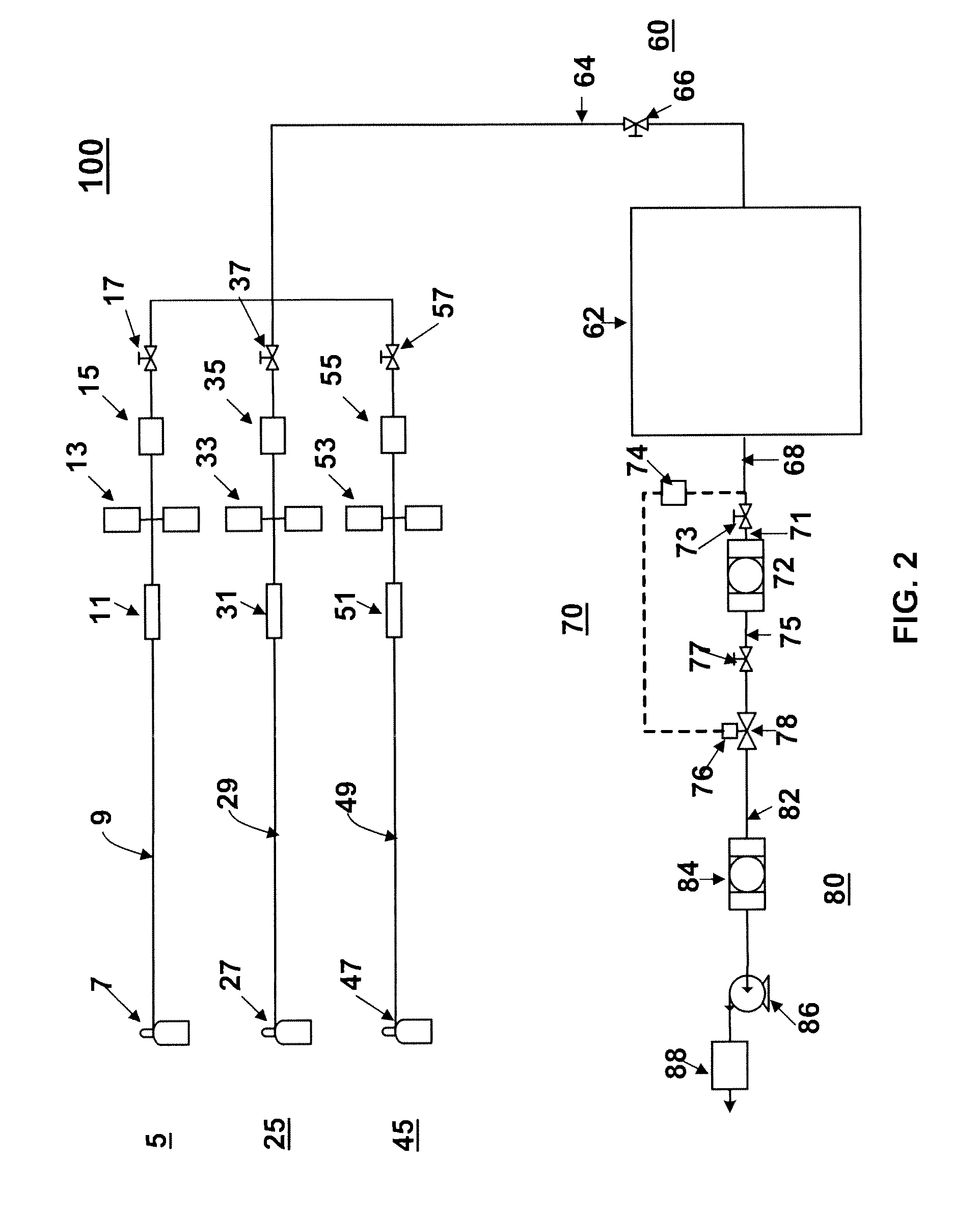

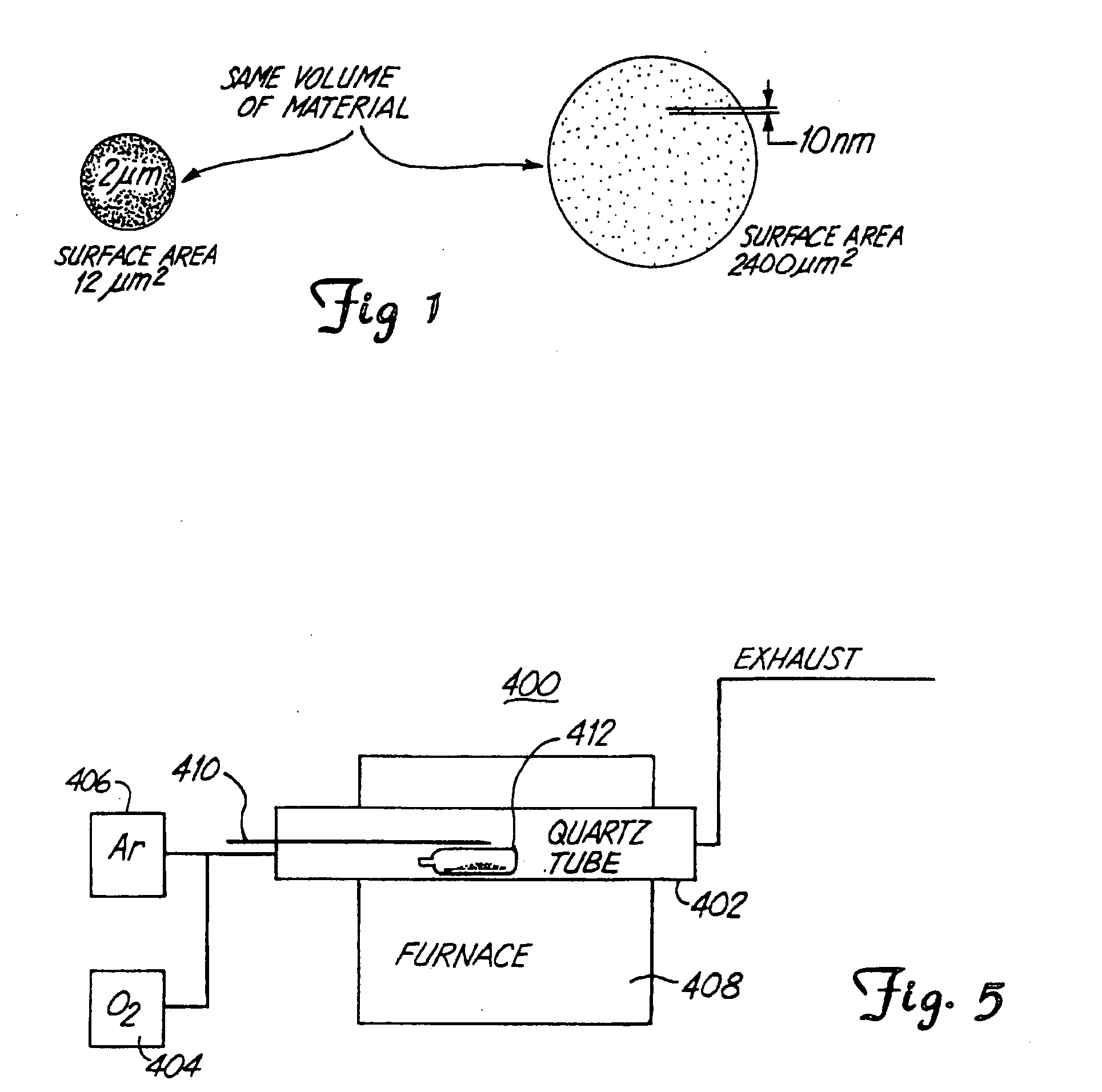

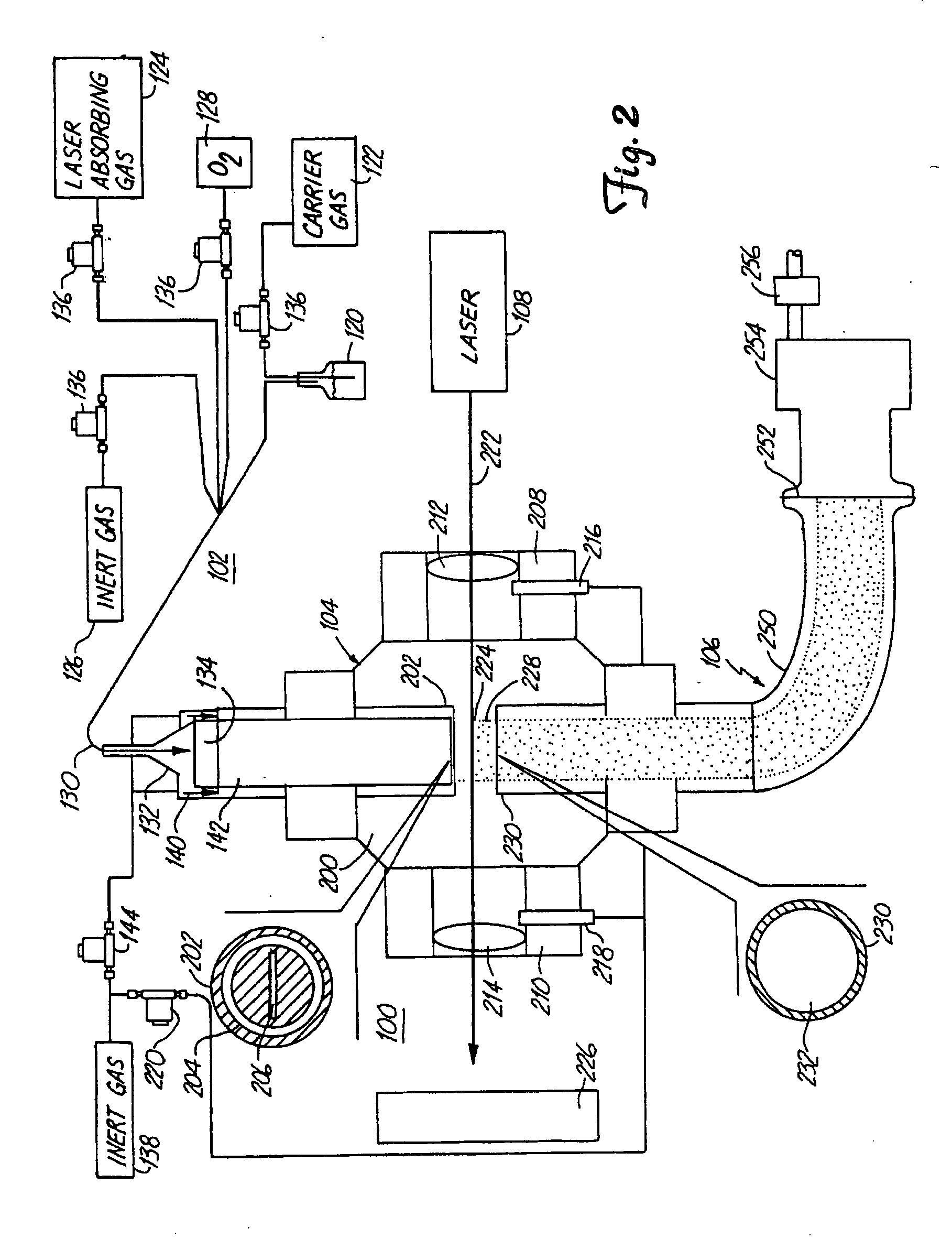

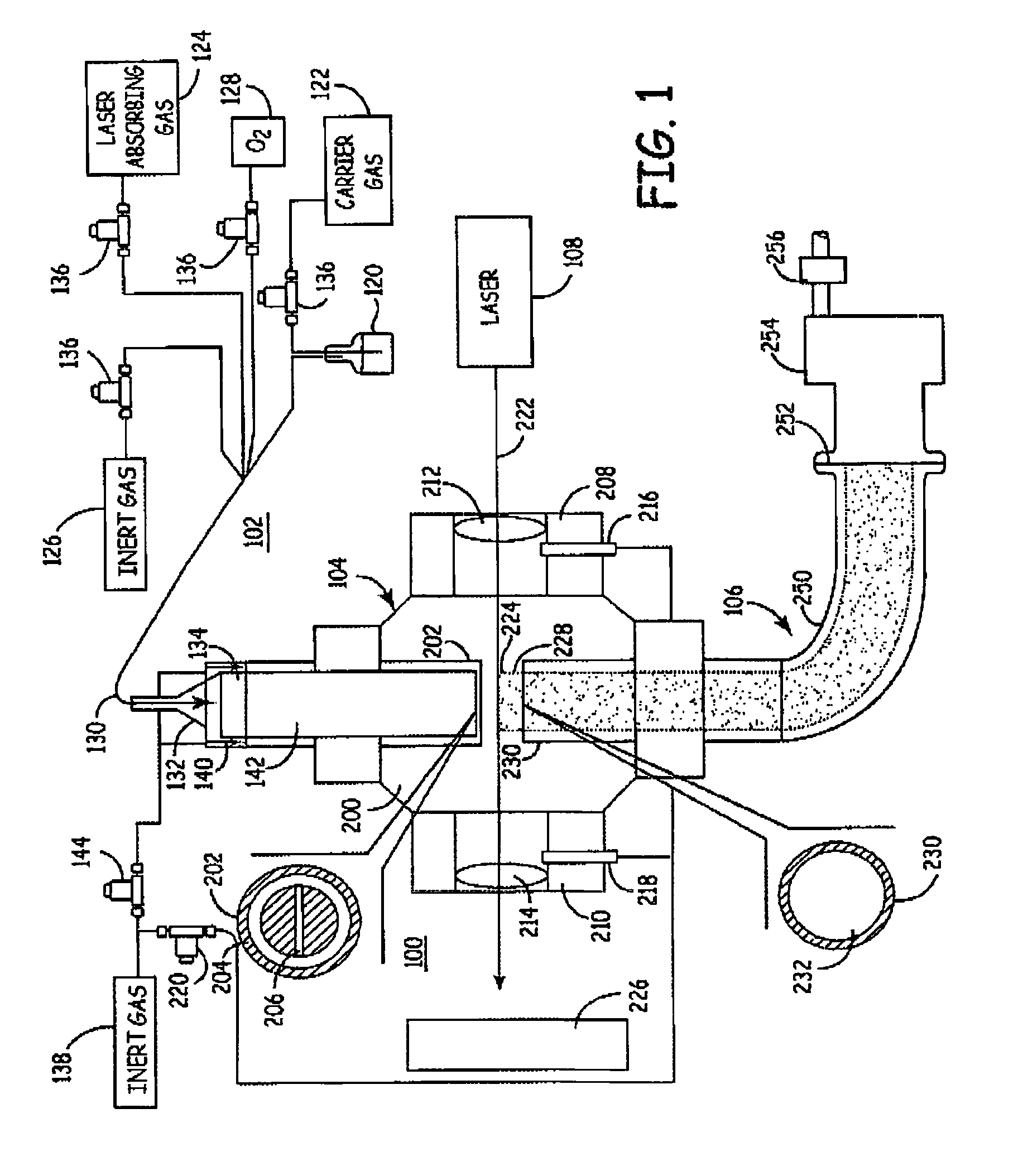

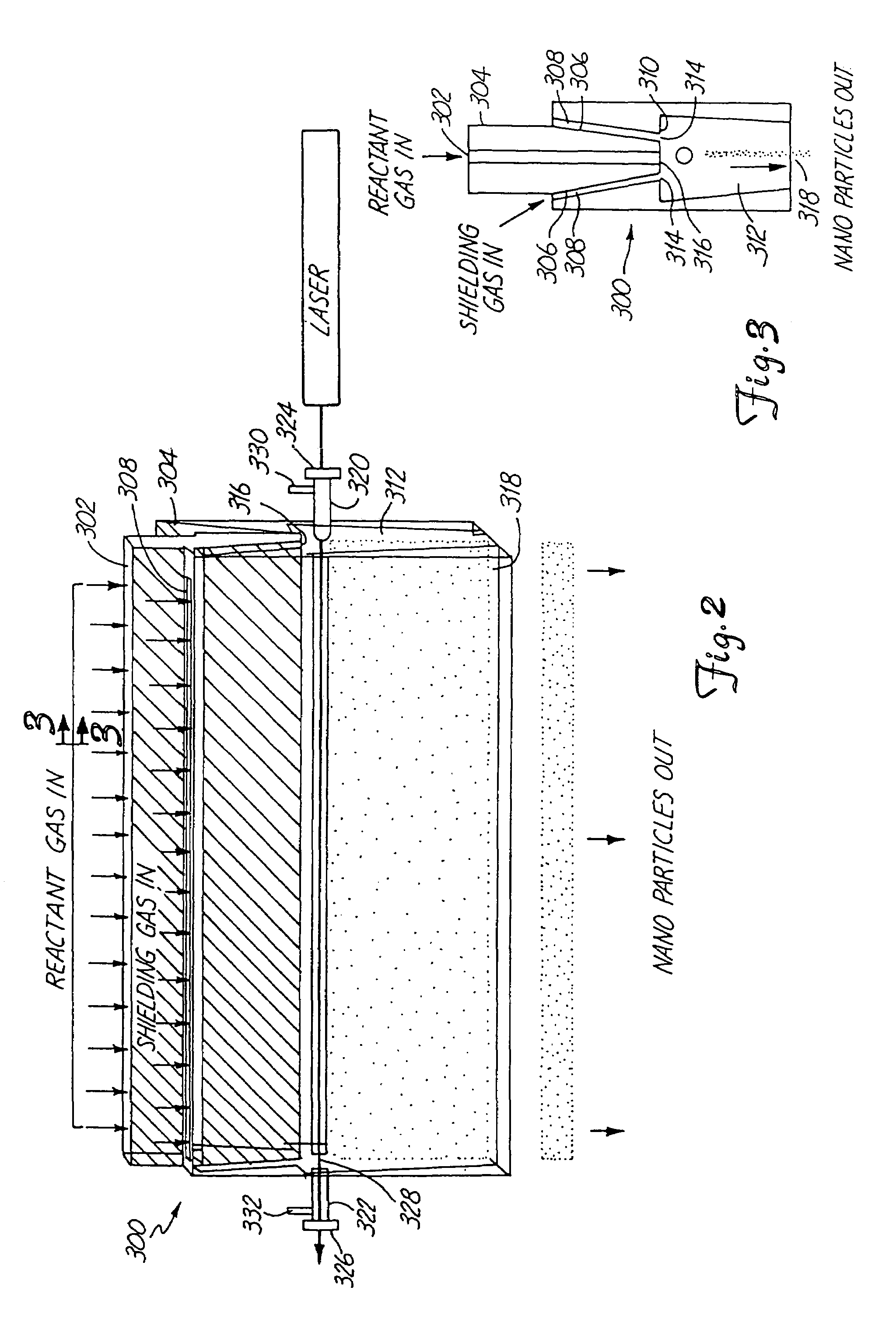

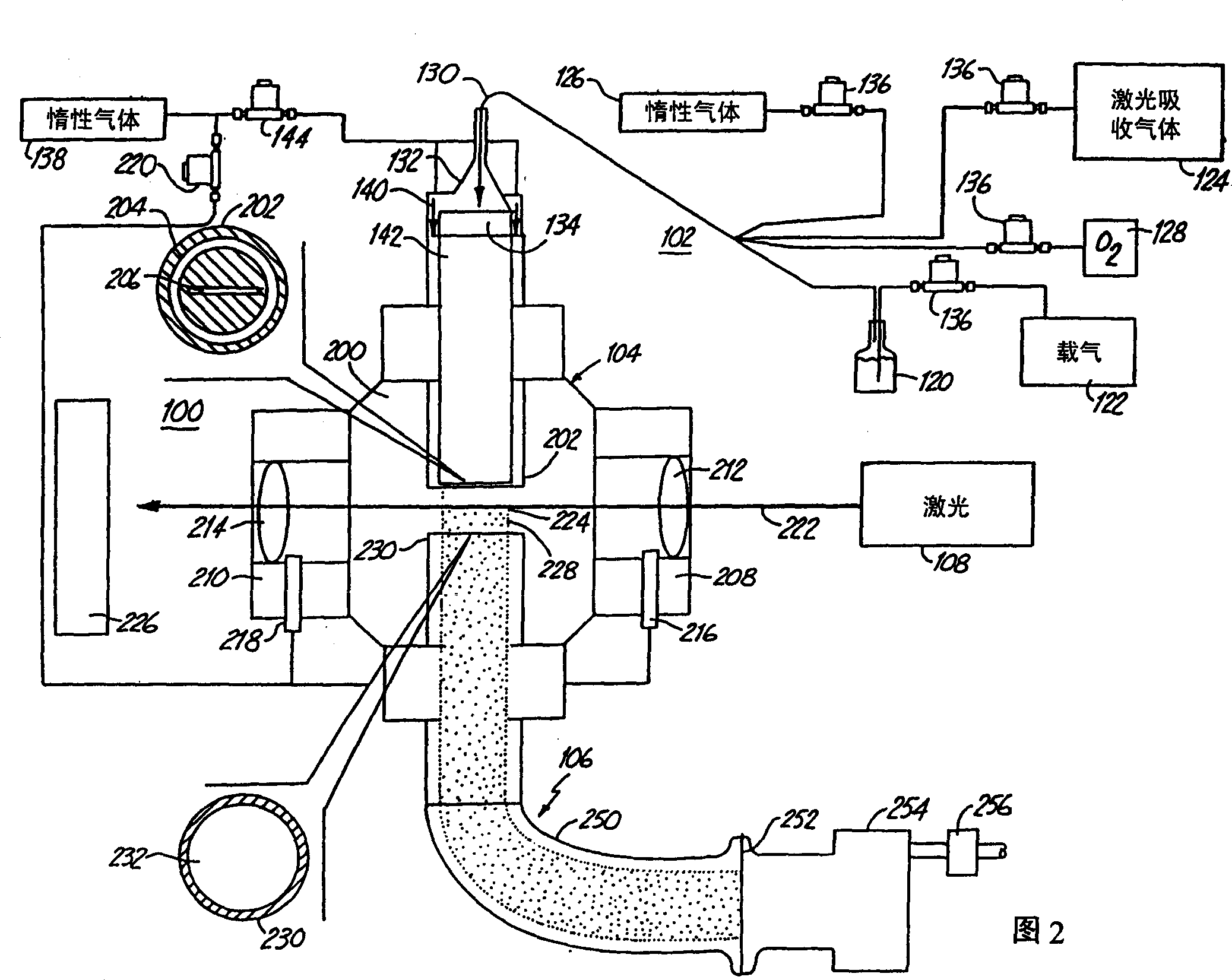

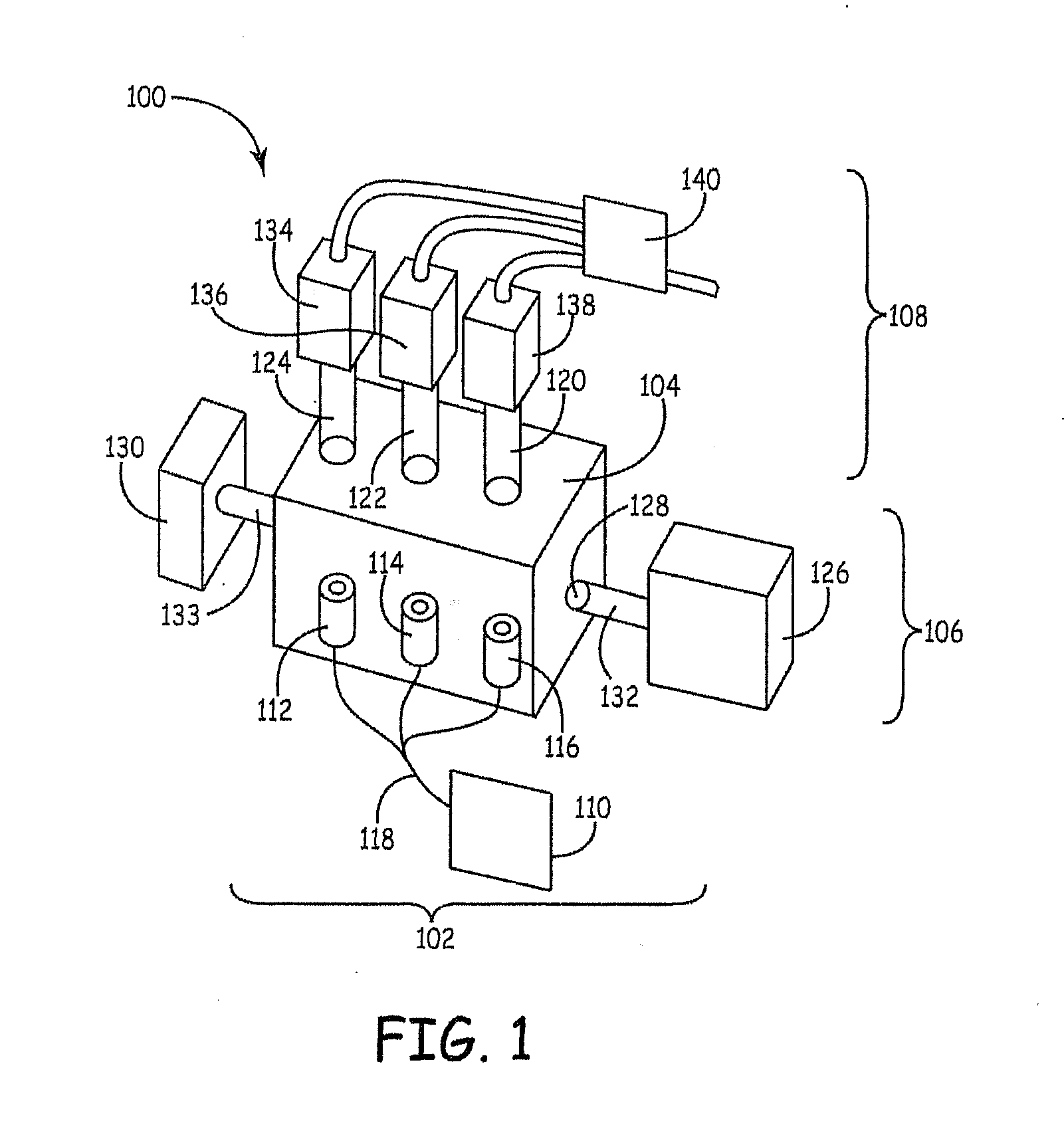

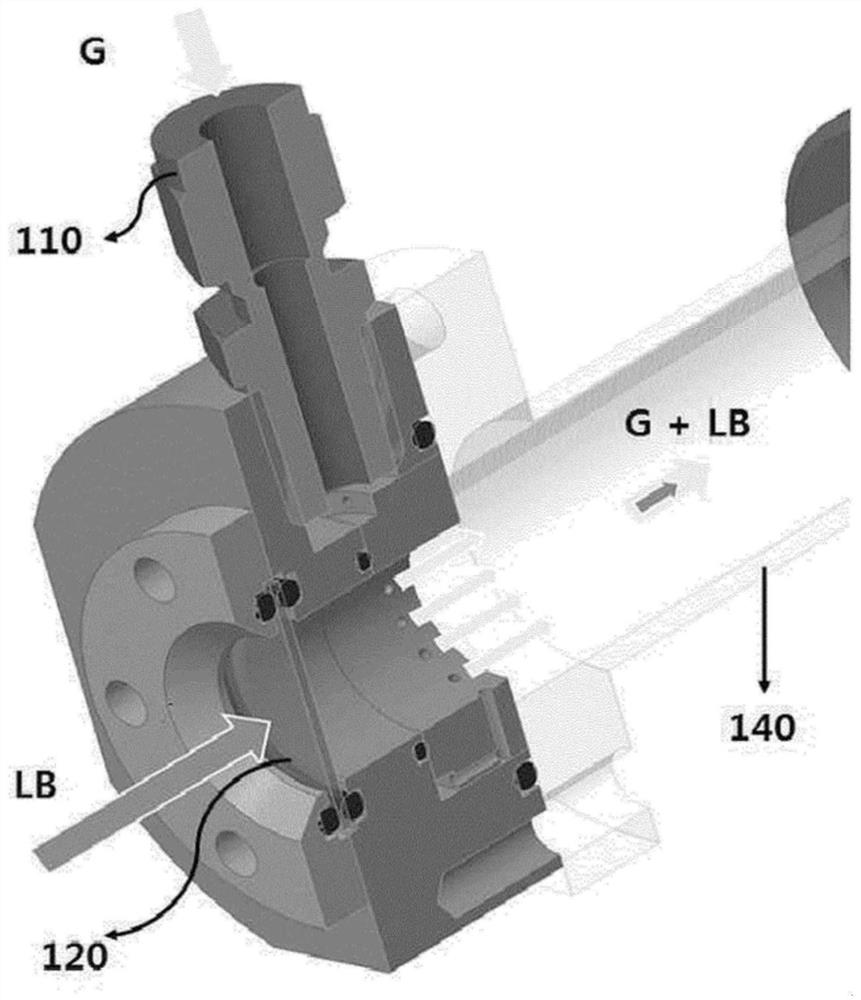

Silicon/germanium nanoparticle inks, laser pyrolysis reactors for the synthesis of nanoparticles and associated methods

InactiveUS20130221286A1Reduce exposureMaterial nanotechnologyFinal product manufactureReactor designSilicon particle

Laser pyrolysis reactor designs and corresponding reactant inlet nozzles are described to provide desirable particle quenching that is particularly suitable for the synthesis of elemental silicon particles. In particular, the nozzles can have a design to encourage nucleation and quenching with inert gas based on a significant flow of inert gas surrounding the reactant precursor flow and with a large inert entrainment flow effectively surrounding the reactant precursor and quench gas flows. Improved silicon nanoparticle inks are described that has silicon nanoparticles without any surface modification with organic compounds. The silicon ink properties can be engineered for particular printing applications, such as inkjet printing, gravure printing or screen printing. Appropriate processing methods are described to provide flexibility for ink designs without surface modifying the silicon nanoparticles.

Owner:NANOGRAM

Method for producing multilayer submicron particles by laser pyrolysis

ActiveUS10611643B2Prevent oxidationInhibitionMaterial nanotechnologySiliconChemical physicsPhysical chemistry

Disclosed is a method for producing particles, including the steps: introducing, into a reaction chamber, at least one reaction flow including a first chemical element and propagating in a direction of flow; projecting a radiation beam through the reaction chamber, intersecting each reaction stream in one interaction area per reaction flow, to form, in each reaction flow, particle cores including the first chemical element; and introducing, into the reaction chamber, a second chemical element interacting with each reaction flow to cover the particle cores with a layer including the second chemical element. Each reaction flow is preferably free of any agent oxidizing the first chemical element. Preferably a ratio of one atom of the second element is introduced per unit of time for at least two atoms of the first element introduced per unit of time. The second element is preferably introduced in at least one confined flow.

Owner:NANOMAKERS

Electrojet three-dimensional printing device and method for preparing micro-nano-scale beam structure

ActiveCN113232317AWide adaptability of materialsShort processing cycleAdditive manufacturing apparatus3D object support structuresCantilevered beamEngineering

The invention belongs to the technical field of advanced manufacturing, and relates to an electrojet three-dimensional printing device and method for preparing a micro-nano-scale beam structure. A three-dimensional fixed support is printed on a substrate drop by drop / stack by stack by using micro-nano-scale electrojet obtained by an electrohydrodynamic effect, and a solvent contained in the three-dimensional fixed support is continuously volatilized when the support is semi-cured and has certain viscosity, a beam structure solution is replaced, printing parameters are adjusted to obtain a micro-nano-scale high-viscosity continuous jet flow, the jet flow is printed on the three-dimensional fixed support, the high-viscosity continuous jet flow and the semi-cured fixed support are fully bonded, a micro-nano simply supported beam structure is obtained after the high-viscosity continuous jet flow and the semi-cured fixed support are completely cured, and the three-dimensional fixed support at one end is removed through high-energy laser pyrolysis or the simply supported beam structure is segmented by utilizing a micro-cutting technology to obtain a micro-nano cantilever beam structure. The printing method for preparing the micro-nano-scale beam structure has the advantages of being wide in material adaptability, short in machining period and the like, and an effective way is provided for efficient and low-cost manufacturing of high-performance devices of a micro-nano-scale beam structure.

Owner:NINGBO UNIV

Synthesis of Silicon Nanocrystals by Laser Pyrolysis

InactiveUS20130189161A1Improve productivityIncrease ratingsMaterial nanotechnologyEnergy based chemical/physical/physico-chemical processesSilicon nanocrystalsCrystal structure

The invention relates to the synthesis of silicon-containing nanoparticles by laser pyrolysis. For this purpose: a precursor (SIH4) containing the element silicon is conveyed, by a transport fluid (He), into a pyrolysis reactor (REAC); laser radiation (LAS) is applied, in the reactor, to a mixture that the transport fluid and the precursor form; and silicon-containing nanoparticles (nP) are recovered at the exit of the reactor. In particular, the power of the laser radiation is controlled. Furthermore, the effective pulse duration is controlled within a laser firing period. Typically, for a power greater than 500 watts and a pulse duration greater than 40% of a laser firing period, nanoparticles having a crystalline structure with a size of less than or of the order of one nanometer are obtained at a rate greater than or of the order of 80 milligrams per hour. Under optimum conditions, a record rate of greater than 740 milligrams per hour was able to be obtained.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Method for generating electricity by combusting domestic garbage through laser pyrolysis

ActiveCN107838172AReduce pollutionGood effectSolid waste disposalTransportation and packagingInfraredCombustion chamber

The invention belongs to the technical field of garbage treatment, and provides a method for generating electricity by combusting domestic garbage through laser pyrolysis. The method comprises the steps that domestic garbage is smashed, pressed and filtered, and water and grease are recycled; solid garbage is subjected to infrared heating and laser treatment to be decomposed, hydrogen, carbon monoxide, methane and other combustible gas are generated, and coke, carbon blank and other solids are left; and combustible gas is fed into a combustion chamber to be combusted for steam power generationor heating through a heating boiler. Compared with a traditional method, the combustible gas obtained through the treatment method is combusted in a clean mode, secondary pollution and stink problemsare greatly relieved, meanwhile, the whole process is low in energy consumption, the labor cost is low, the garbage utilization rate s high, the additional value is high, and remarkable environmentalprotection advantages and good economic advantages are obtained.

Owner:玉环市星光眼镜厂

A method for growing high-entropy alloy nanoparticles on flexible substrates

ActiveCN112935274BAvoid high temperature heat damageAchieve growthMaterial nanotechnologyTransportation and packagingHigh entropy alloysThin membrane

The invention provides a method for growing high-entropy alloy nanoparticles on a flexible substrate, comprising: obtaining a flexible substrate; growing a three-dimensional graphene film with a preset shape on the flexible substrate by using a laser direct writing technology; A precursor solution of entropy alloy nanoparticles; dropping the precursor solution on the three-dimensional graphene film to form a pretreated sample; using laser direct writing technology to irradiate the three-dimensional graphene film on the pretreated sample Heat treatment to obtain the high-entropy alloy nanoparticles. Based on the above technical solution, the uniformity of the size of the high-entropy alloy nanoparticles and the total loading of the alloy can be effectively improved; and the high-temperature thermal damage to the flexible substrate can be effectively avoided; at the same time, the pulsed laser pyrolysis growth mechanism is also conducive to obtaining a single Phases of high-entropy alloy nanoparticles.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

A method for laser cracking polysilazane precursors to prepare ceramic coatings

ActiveCN105821400BImprove high temperature resistanceLow preparation temperatureSolid/suspension decomposition chemical coatingHeat-affected zoneSilazane

Owner:ACADEMY OF ARMORED FORCES ENG PLA

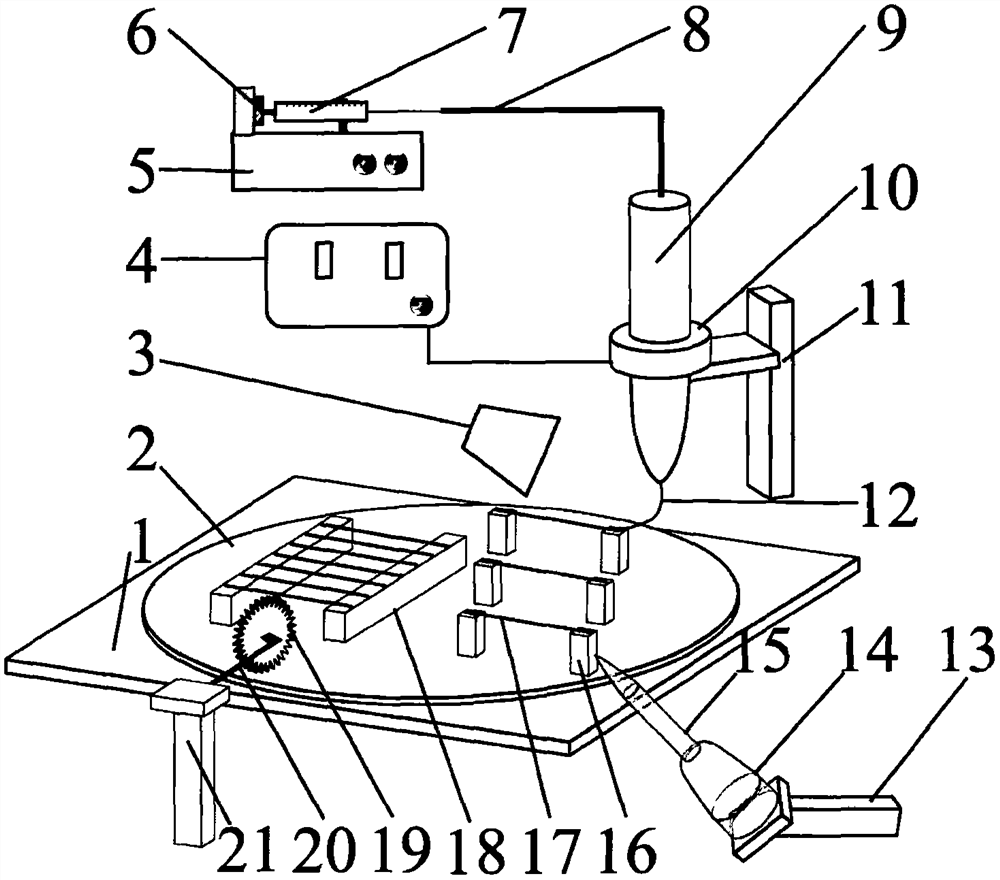

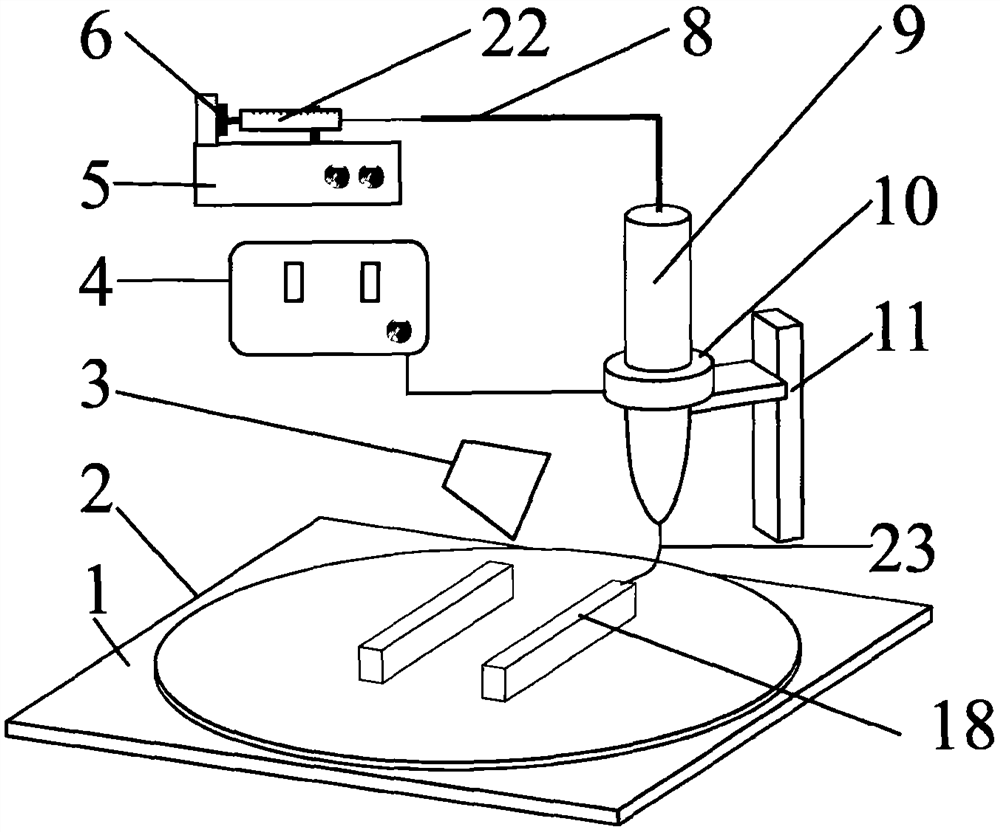

NANO particle synthesis apparatus and NANO particle synthesis method using same

PendingCN111615426AHomogeneous pyrolysis reactionSmall sizePyrolysis reactionsEnergy based chemical/physical/physico-chemical processesLaser pyrolysisNanotechnology

Owner:LG CHEM LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com