Method for producing a powder including carbon, silicon and boron

A powder, silicon carbide technology, applied in nanotechnology for materials and surface science, chemical instruments and methods, silicon carbide, etc., can solve problems such as high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

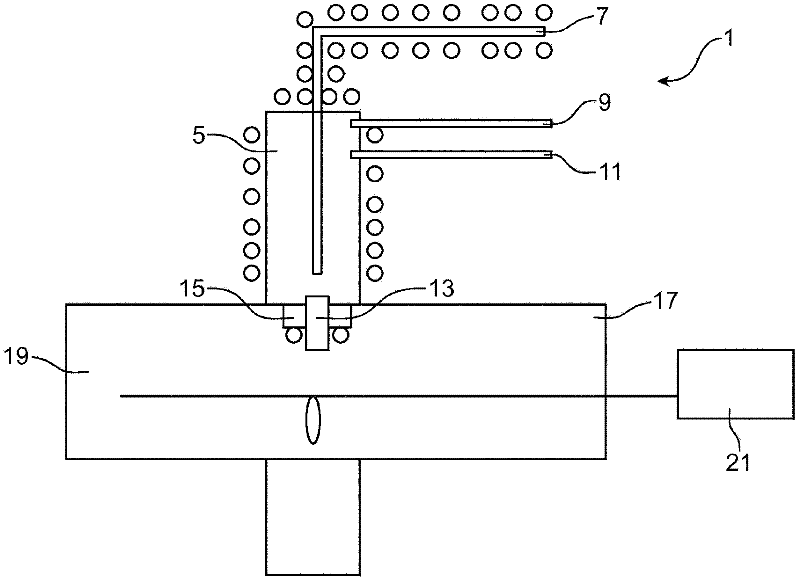

[0064] This example illustrates the preparation of a powder comprising both silicon carbide and boron carbide phases by laser pyrolysis, at figure 1 in Reactor 1 shown in , which contains the following elements:

[0065] - an injection chamber into which the precursors are injected before being subjected to laser pyrolysis and then mixed, said chamber consisting of a heated mixing chamber 5, an injection rod 7 connected to the upper part of the chamber, two rods connected to the sides of the chamber injection rods 9, 11 so that the mixture is injected into the injection nozzle 13 within the pyrolysis chamber; a confinement flue 15 arranged around the injection nozzle;

[0066] - a pyrolysis chamber 17, in which a laser beam 19 is emitted from a laser emitting device 21, which will interact with the precursor mixture to form the above-mentioned powder.

[0067] The confinement lip firstly allows the powder produced to be contained in a laminar flow, and secondly it prevents an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com