A method for laser cracking polysilazane precursors to prepare ceramic coatings

A technology of polysilazane and ceramicization, which is applied in the direction of coating, metal material coating process, solid-state chemical plating, etc., which can solve the problems of increased difficulty in finished product preparation, difficult control of laser scanning conditions, and increased difficulty in PDC control. , to achieve the effects of designable and adjustable structure and performance, abundant precursors, and concentrated energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

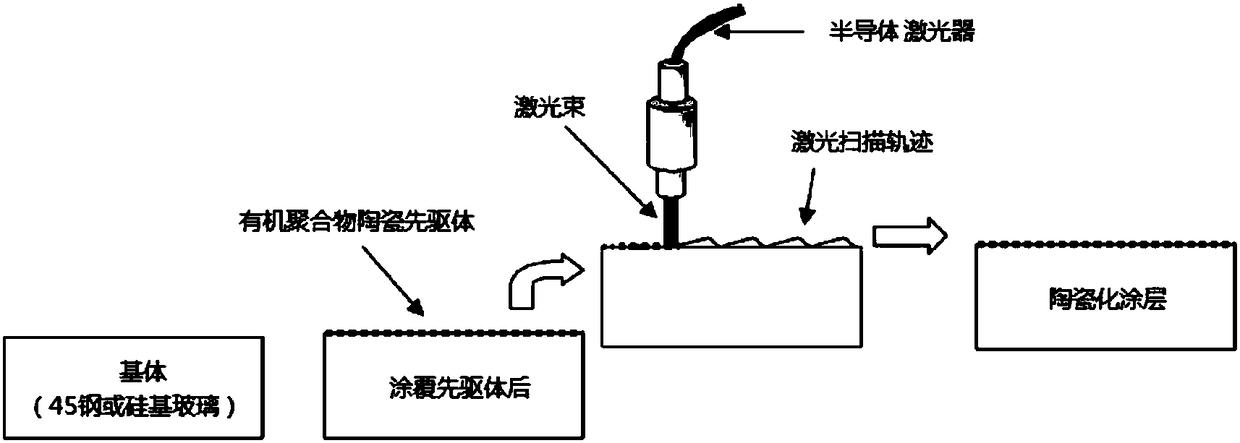

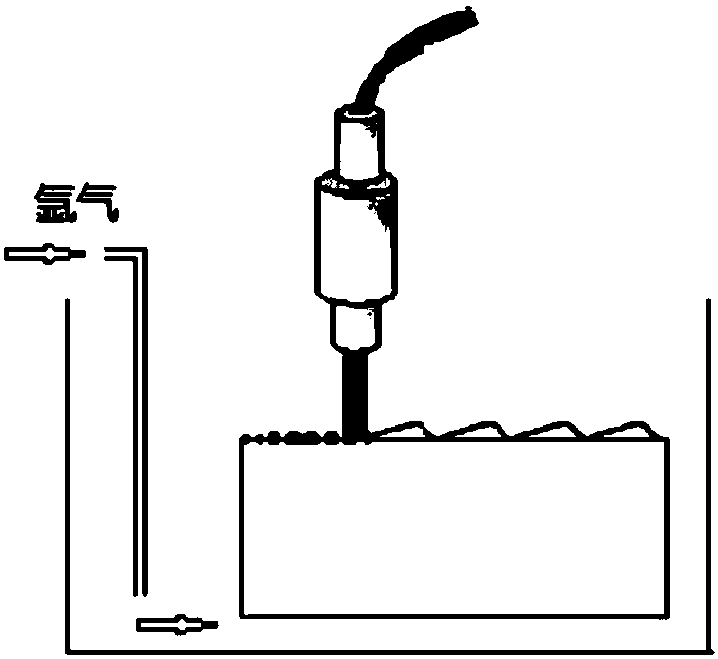

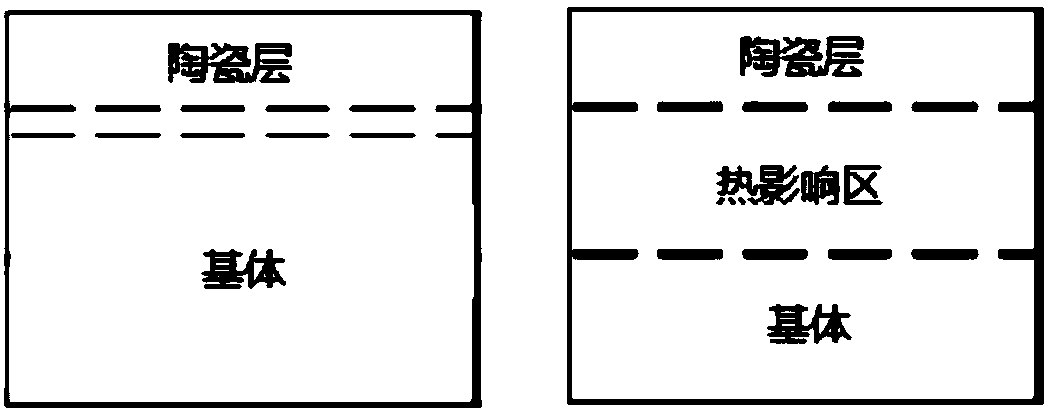

Method used

Image

Examples

Embodiment 1

[0035]The precursor component of this example is PSZ1 (Polysilazane 1), a low-viscosity liquid organic polysilazane polymer with an average molecular weight of 600-1000 and composed of repeating Si-N units. The laser is a DLS-3000C continuous high-power semiconductor laser , Laser wavelength 980nm, maximum output power 3KW, spot size 14mm×2.5mm, working distance 310±10mm.

[0036] The preparation method of above-mentioned ceramic coating is made up of the following steps:

[0037] step one:

[0038] Sandblast the substrate (a 45 steel sample block with a length of 20mm, a width of 20mm, and a height of 5mm), then clean it with ethanol and acetone, and dry it for later use.

[0039] Step two:

[0040] Coat 30% xylene solution of organic polymer ceramic precursor PSZ1 on the surface of the substrate, remove the solvent by vacuuming with an oil pump, and cure in vacuum at a rate of 5°C / min from room temperature (18°C) to 130°C to form a thickness of about 1mm prefabricated lay...

Embodiment 2

[0044] The precursor component of this example is PSZ2 (Polysilazane2), a low-viscosity liquid organic polysilazane polymer with an average molecular weight of 500-900 and composed of repeating Si-N units. The laser is a DLS-3000C continuous high-power semiconductor laser , The laser wavelength is 980nm, the maximum output power is 3KW, the spot size is 14mm×2.5mm, and the working distance is 310mm±10mm.

[0045] The preparation method of above-mentioned ceramic coating is made up of the following steps:

[0046] step one:

[0047] Sandblast the substrate (a 45 steel sample block with a length of 20mm, a width of 20mm, and a height of 5mm), then clean it with ethanol and acetone, and dry it for later use.

[0048] Step two:

[0049] Coat 50% xylene solution of organic polymer ceramic precursor PSZ2 on the surface of the substrate, remove the solvent by vacuuming with an oil pump, and solidify in a vacuum at a rate of 5°C / min from room temperature (18°C) to 130°C to form a la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com