Electrojet three-dimensional printing device and method for preparing micro-nano-scale beam structure

A three-dimensional printing, micro-nano-scale technology, applied in 3D object support structures, additive manufacturing, manufacturing tools, etc., can solve the problems of high cost, complex process, increase manufacturing cost and cycle, etc., to achieve low-cost manufacturing, material adaptability The effect of wide and short processing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

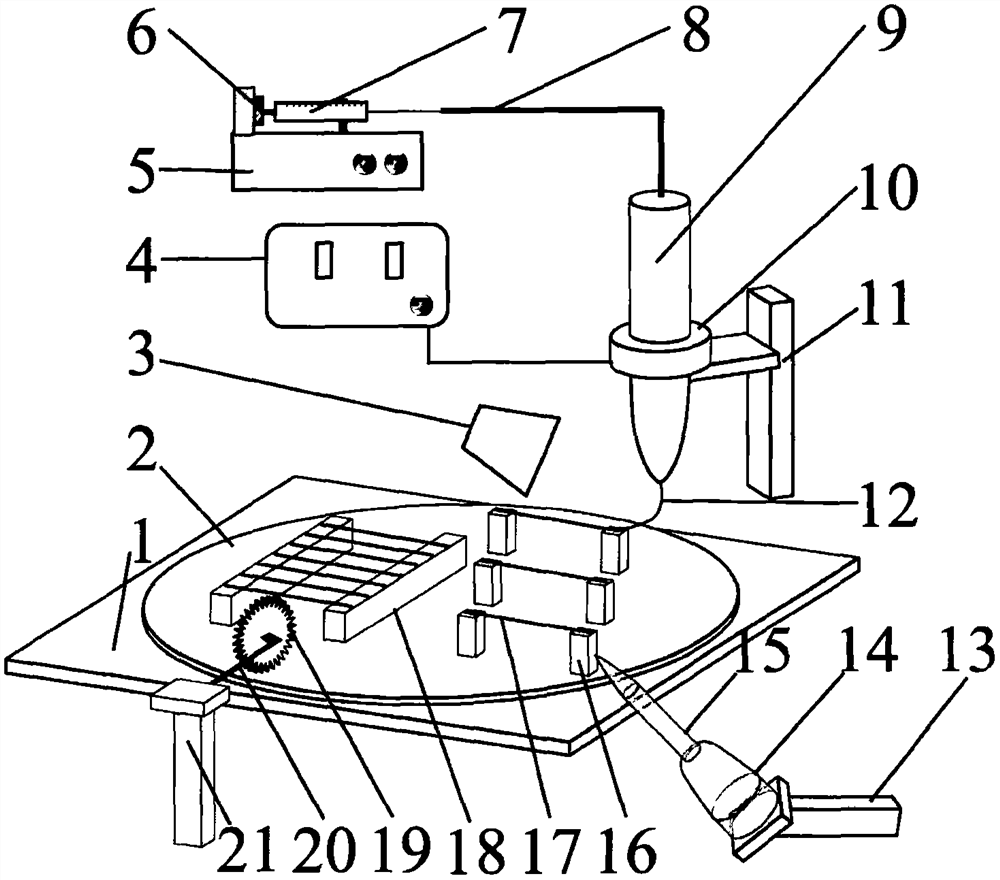

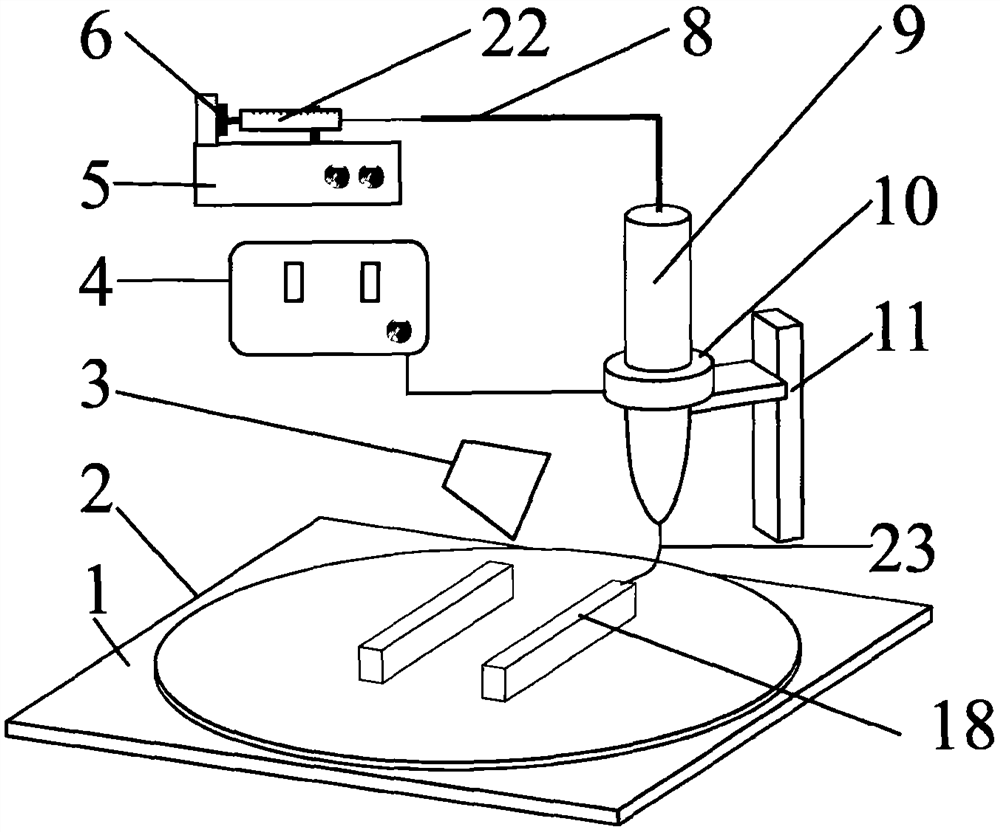

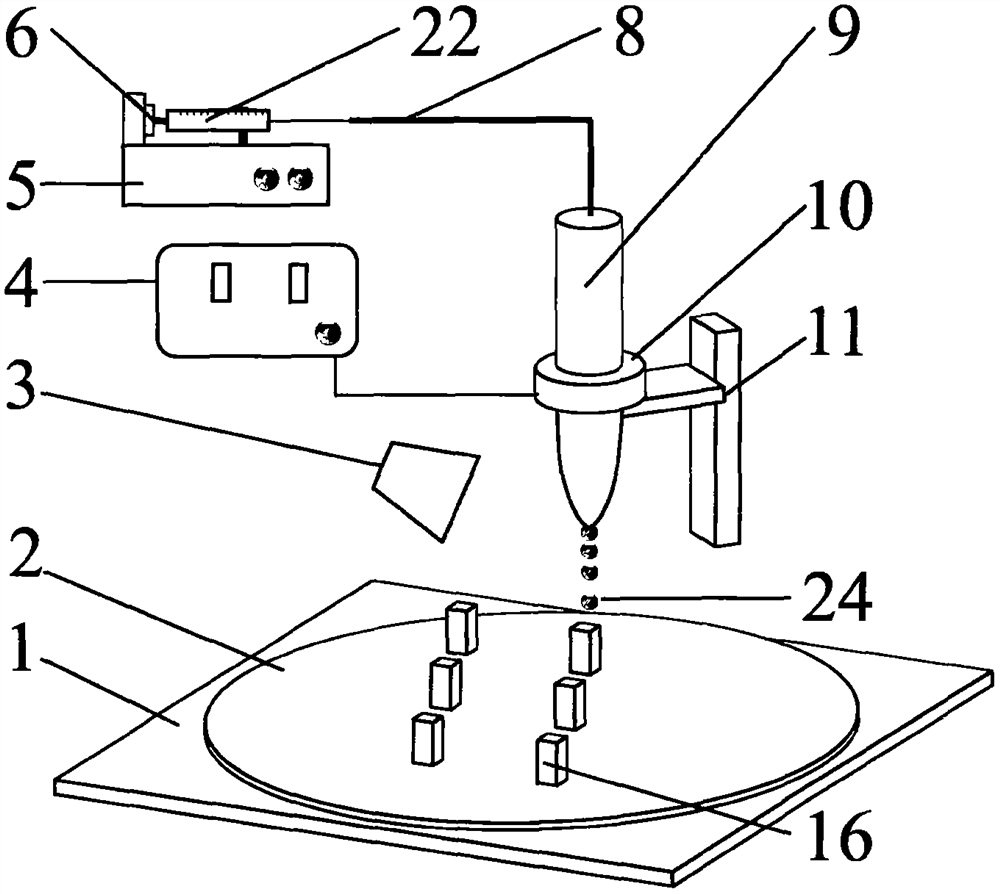

[0022] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings. see Figure 1 to Figure 6 .

[0023]This embodiment discloses an electro-jet three-dimensional printing device for preparing micro-nano-scale beam structures. The device uses micro-nano-scale jets or droplets formed by focusing on the electrohydrodynamic effect to print drop by drop / stack by stack to prepare three-dimensional fixed beams. When the solvent in the support volatilizes to semi-cured and the viscosity is suitable, print a micro-nano scale high-viscosity continuous jet on it, and the high-viscosity continuous jet is fully bonded and solidified with the semi-cured support to form a micro-nano beam structure. The high-energy laser pyrolysis removes the three-dimensional fixed support at one end or uses the micro-cutting technology to divide the simply supported beam structure to obtain the micro-n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com