A clean micro-charge process suitable for mems micro-thruster array chip

An array chip and micro propulsion technology, which is applied in jet propulsion devices, machines/engines, rocket engine devices, etc., can solve the problems of low bonding strength and low bonding efficiency between the micro-chamber array layer and the micro-nozzle array layer. High, troubled MEMS micro thruster array chip preparation and performance issues, to achieve the effect of wide material adaptability, high precision and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] A clean micro-charge process suitable for MEMS micro-thrust array chips, comprising the following steps:

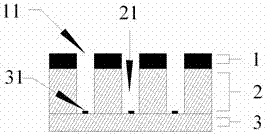

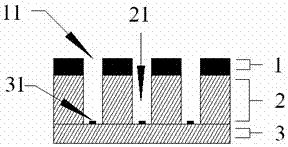

[0020] 1) According to the diameter and distribution of the micro-chamber array layer 2, the corresponding separator micro-through holes 11 are processed on the separator 1 with the micro-hole array, and the separator 1 with the micro-hole array is fixed on the The surface of the micro-chamber array layer 2;

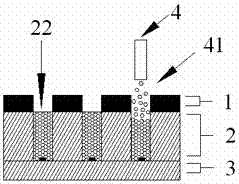

[0021] 2) Filling the propellant energetic material in the micropowder chamber 22 after the charge is completed;

[0022] 3) After completing the charging process of the micro-chamber array layer 2, remove the partition plate 1 with the micro-hole array on the surface of the micro-chamber array layer 2, exposing the micro-chamber array layer 2 protected by the partition plate 1 with the micro-hole array Clean process surface;

[0023] 4) Perform subsequent bonding steps to improve bonding efficiency and bonding performance by ensuring the cleanliness of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com