High-strength fiber shearing device

A high-strength fiber and shearing device technology, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of unfavorable mass production, low tool life, and large tool wear, and achieve wide material adaptability , high cutting quality, high flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

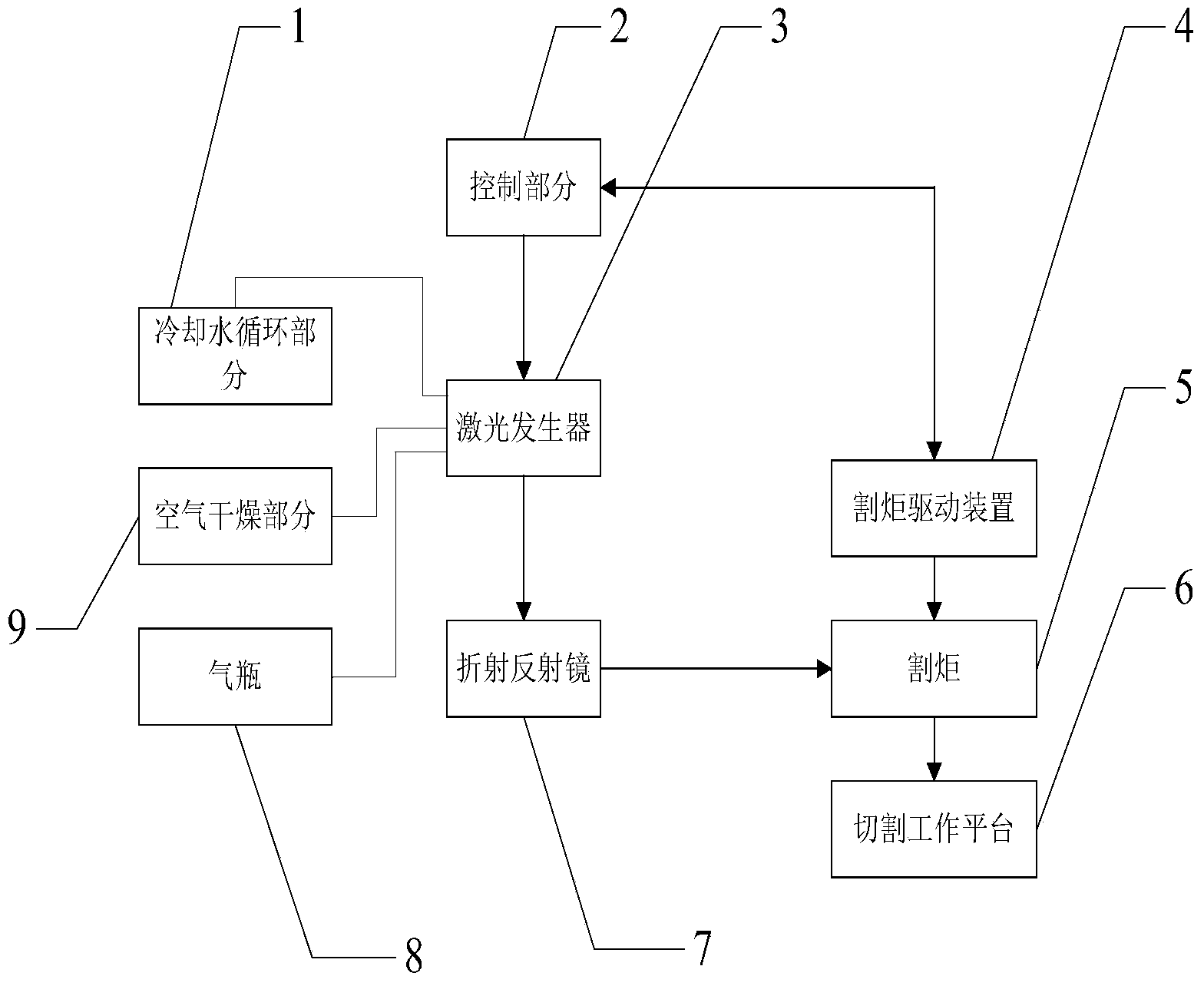

[0030] In order to better understand the technical content of the present invention, the specific embodiments are specifically cited and described as follows in conjunction with the accompanying drawings:

[0031] Such as figure 1 As shown, a kind of high-strength fiber shearing device proposed by the present invention adopts the following technical scheme, and the system includes:

[0032] Control part 2, to complete the automatic control of the device;

[0033] Laser generator 3; equipment for generating laser light;

[0034] The gas cylinder 8 is used to supplement the working gas used by the laser generator 3 and supply auxiliary gas for cutting;

[0035] The cooling water circulation part 1 is used for cooling the laser generator 3;

[0036] Air dryer 9 is used to provide clean dry air to laser generator 3;

[0037] Refractive mirror 7; used to guide the laser to the desired place;

[0038] Cutting torch 5, completes the cutting work to fiber;

[0039] The cutting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com