A cotton web cutting device

A technology for cutting devices and cotton webs, applied in measuring devices, textiles, papermaking, instruments, etc., can solve problems such as inability to cut neatly at one time, flexible fibers cannot be cut neatly, etc., achieve high cutting efficiency, convenient use and operation, and easy operation simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

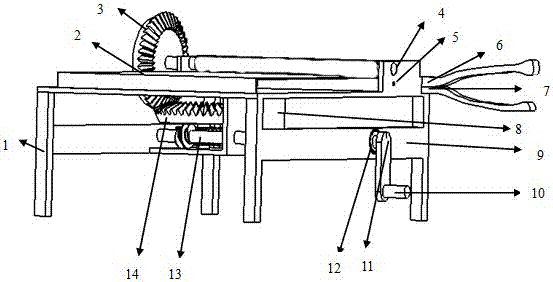

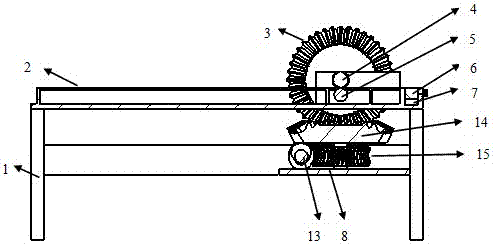

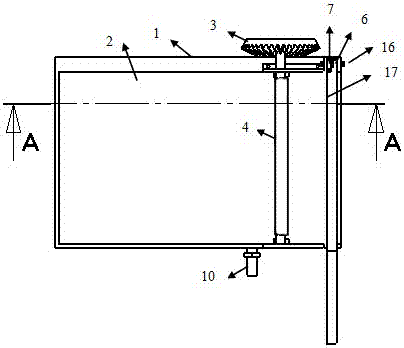

[0024] The present invention will be further elaborated below by means of the accompanying drawings and examples.

[0025] A cotton web cutting device, such as figure 1 , figure 2 and image 3 As shown, a base 1 is included, and a loading platform 2 is arranged on the base 1. The loading platform 2 is smooth, which reduces the frictional force of the cotton web sliding on it.

[0026] The lower end of the stage 2 is provided with a transmission box 8, the transmission box 8 is located on one side of the base 1, and the other side of the base 1 is provided with a base strip 9. The transmission box 8 is provided with a worm screw 13, a worm wheel 15 and a horizontal bevel gear 14. Worm screw 13 is connected with worm gear 15, and worm screw screw 13 and worm gear 15 form worm and gear mechanism, and the transmission ratio of worm screw screw 13 and worm gear 15 is 1:40, and worm screw screw is 40 teeth, and worm screw screw 13 rotates one circle, and worm gear 15 rotates one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com