Ammonia decomposition device, ammonia decomposition system and hydrogen production method

A technology of ammonia decomposition and heat exchange device, which is applied in the field of hydrogen production, can solve the problems of high residual ammonia gas and incomplete decomposition of ammonia gas, and achieve the effects of improving decomposition efficiency, complete decomposition, and improving device compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

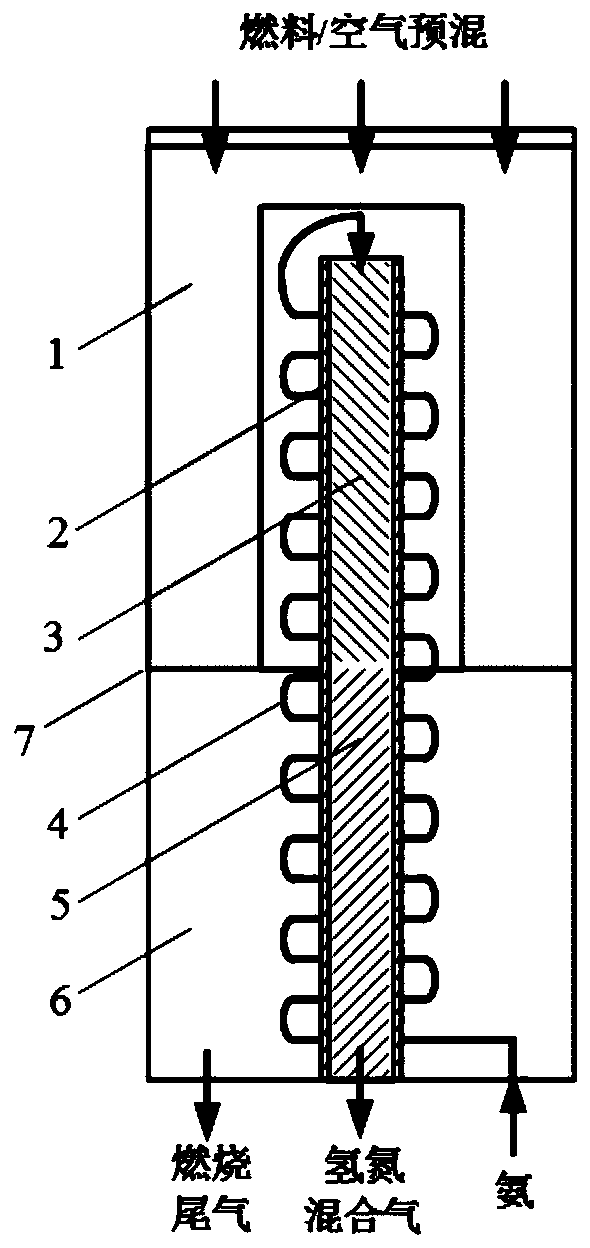

[0047] This embodiment provides an ammonia decomposition device, the structure is shown in figure 1 , including a shell, along the length direction of the shell, the shell includes a heating zone and a heat exchange zone 6 connected in sequence;

[0048] The reaction section 2 includes the first reaction section 3 and the second reaction section 5 which are connected in sequence. The first reaction section is arranged in the heating zone and filled with a nickel-based catalyst to form a nickel-based catalyst layer. The second reaction section is arranged at The heat exchange zone is filled with a ruthenium-based catalyst to form a ruthenium-based catalyst layer; specifically, in this embodiment, the reaction section 2 is a fixed-bed reactor, and the height-to-diameter ratio of the fixed-bed reactor is 8:1. The first reaction section and the second reaction section are arranged in the same fixed bed reactor, the first reaction section 3 is arranged in the fixed bed reactor clos...

Embodiment 2

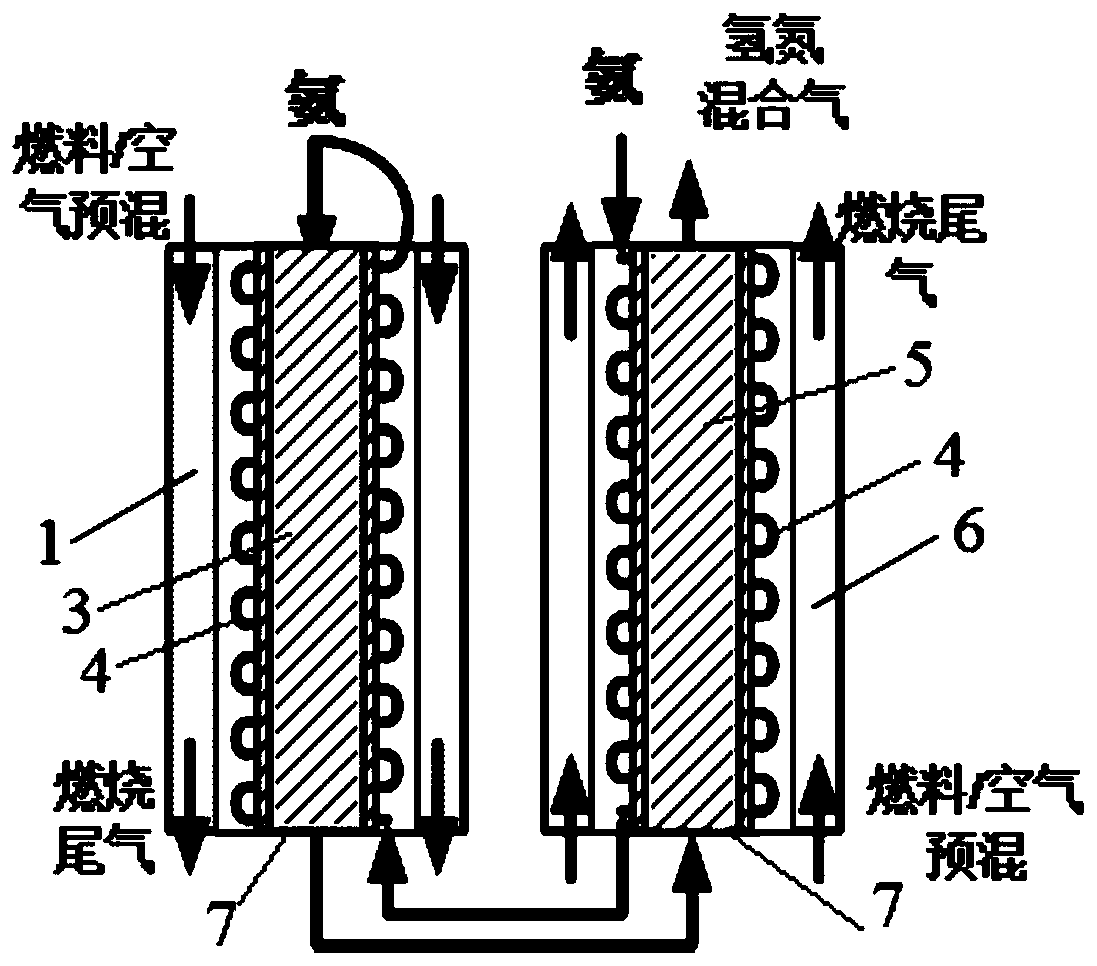

[0059] This embodiment provides an ammonia decomposition device, the structure is shown in image 3 , comprising a shell, and further comprising a sequentially connected heating zone and a heat exchange zone 6, wherein the heating zone and the heat exchange zone are communicated side by side through channels;

[0060] The reaction section includes the first reaction section 3 and the second reaction section 5 which are connected in sequence. The first reaction section is arranged in the heating zone and filled with a nickel-based catalyst to form a nickel-based catalyst layer. The second reaction section is arranged in the heating zone. In the hot zone and filled with a ruthenium-based catalyst to form a ruthenium-based catalyst layer; specifically, in this embodiment, the reaction section is a fixed-bed reactor, and the height-to-diameter ratio of the fixed-bed reactor is 5:1. The first reaction The first section and the second reaction section are respectively arranged in tw...

Embodiment 3

[0071] This embodiment provides an ammonia decomposition device, the structure is shown in figure 1 , including a shell, along the length direction of the shell, the shell includes a heating zone and a heat exchange zone 6 connected in sequence;

[0072] The reaction section 2 includes the first reaction section 3 and the second reaction section 5 which are connected in sequence. The first reaction section is arranged in the heating zone and filled with a nickel-based catalyst to form a nickel-based catalyst layer. The second reaction section is arranged at The heat exchange zone is filled with a ruthenium-based catalyst to form a ruthenium-based catalyst layer; specifically, in this embodiment, the reaction section 2 is a fixed-bed reactor, and the height-to-diameter ratio of the fixed-bed reactor is 8:1. The first reaction section and the second reaction section are arranged in the same fixed bed reactor, the first reaction section 3 is arranged in the fixed bed reactor clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com