Method and device for synthesizing phenyl chlorosilane

A technology of phenylchlorosilane and synthesis method, which is applied in the direction of silicon organic compounds, chemical methods for reacting gas medium with gas medium, chemical instruments and methods, etc., which can solve the problems of tail gas system blockage, low reaction efficiency, poor selectivity, etc. , to avoid system blockage, high conversion rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

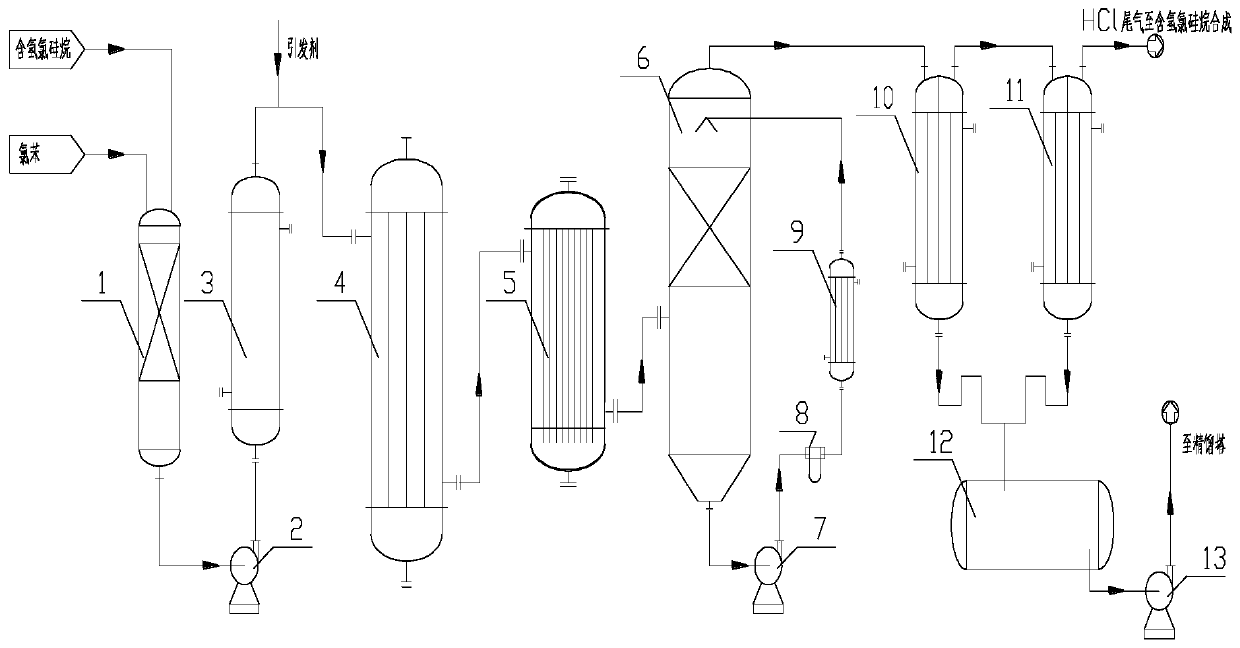

[0036] The invention provides a kind of synthetic method of phenylchlorosilane, comprising steps:

[0037] S1, raw material mixing and vaporization: After mixing hydrochlorosilane and chlorobenzene in a certain proportion, heat the mixture to vaporize;

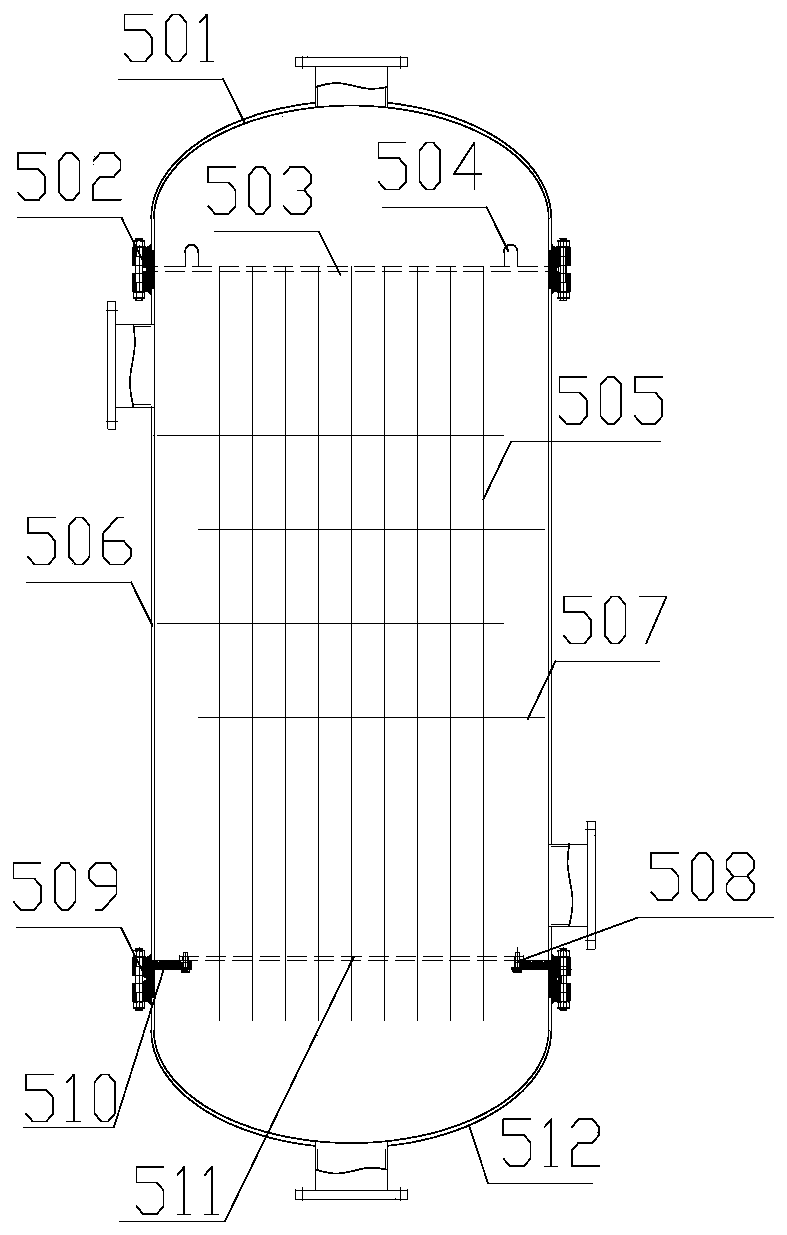

[0038] S2, thermal condensation reaction: the vaporized mixture is heated together with the initiator to a certain temperature and then enters the reactor for thermal condensation reaction to generate a mixed gas containing phenylchlorosilane;

[0039] S3, cooling and washing the product: cooling and washing the mixed gas containing phenylchlorosilane;

[0040] S4, Separation of phenylchlorosilane: Condensate and lower the temperature of the mixed gas containing phenylchlorosilane after cooling and washing. Part of the components in the mixed gas are liquefied to obtain crude phenylchlorosilane, and the remaining non-condensable gas is sent to the hydrogen-containing chlorine Silane synthesis furnace;

[0041] S5: Purificati...

Embodiment 1

[0097] The synthetic method of phenylchlorosilane described in this embodiment is carried out according to the following steps:

[0098] S1, raw material mixing and vaporization: After mixing trichlorosilane and chlorobenzene in a molar ratio of 2:1, heat to 100°C to vaporize the mixture;

[0099] S2, Thermal condensation reaction: The vaporized mixture is heated together with cumene hydroperoxide to 200°C and then enters the reactor for thermal condensation reaction. It reacts for 50s at a temperature of 400°C and a pressure of 0.01MPaG to generate phenyl chloride Mixed gas of silane;

[0100] S3, cooling and washing the product: cooling and washing the mixed gas containing phenylchlorosilane to 80 °C by using a circulating cooling liquid with a temperature of 50 °C;

[0101] S4, Separation of phenylchlorosilane: Condensate and lower the temperature of the mixed gas containing phenylchlorosilane after cooling and washing. Part of the components in the mixed gas are liquefied...

Embodiment 2

[0106] The synthetic method of phenylchlorosilane described in this embodiment is carried out according to the following steps:

[0107] S1, raw material mixing and vaporization: after mixing dichlorodihydrosilane and chlorobenzene in a molar ratio of 0.9:1, heat to 150°C to vaporize the mixture;

[0108] S2, thermal condensation reaction: the vaporized mixture is heated together with chloroform to 500°C and enters the reactor for thermal condensation reaction, and reacts for 100s at a temperature of 600°C and a pressure of 0.08MPaG to generate a mixed gas containing phenylchlorosilane;

[0109] S3, cooling and washing the product: cooling and washing the mixed gas containing phenylchlorosilane to 180 °C by using a circulating cooling liquid with a temperature of 150 °C;

[0110] S4, Separation of phenylchlorosilane: Condensate and lower the temperature of the mixed gas containing phenylchlorosilane after cooling and washing. Part of the components in the mixed gas are liquefi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com