Apparatus for producing trichlorosilane

A trichlorosilane, a technology for manufacturing devices, applied in the direction of halosilane, silicon compounds, silicon halide compounds, etc., can solve the problems of easy cracks or cracks, large temperature difference, etc., and achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

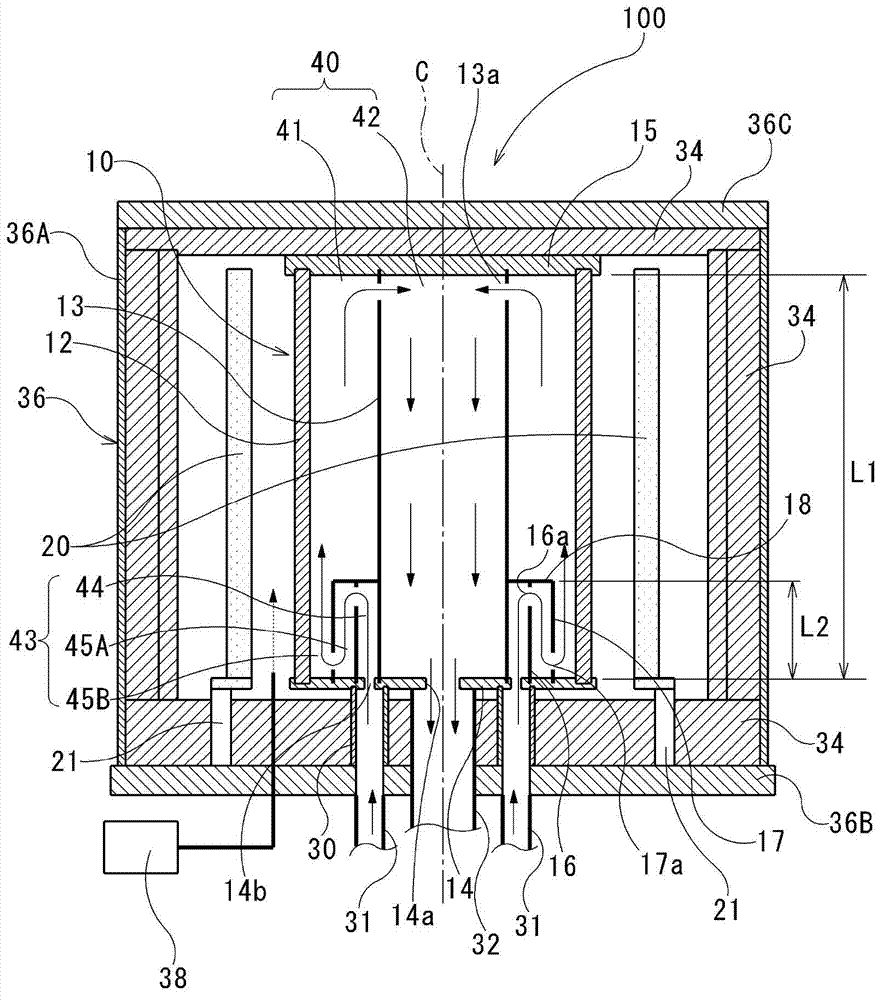

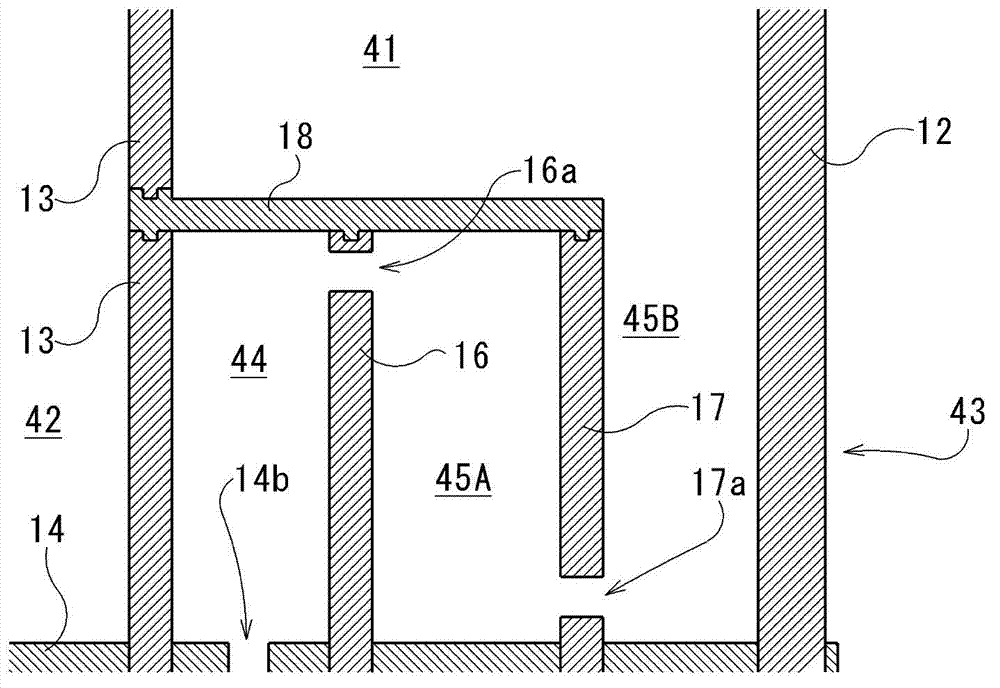

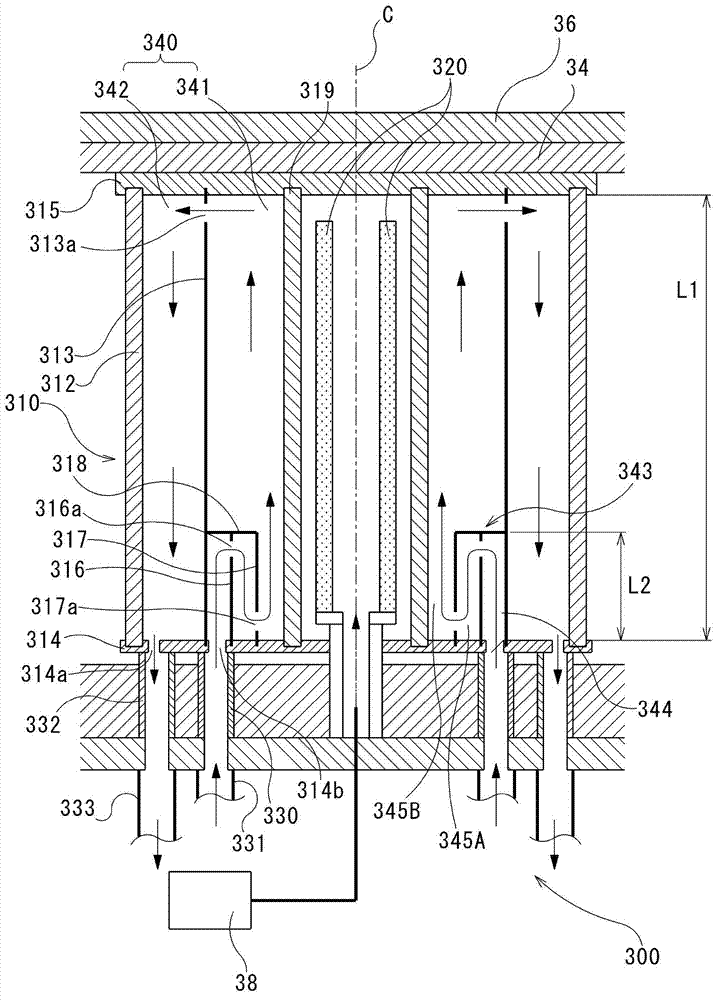

[0023] Hereinafter, embodiments of the trichlorosilane production apparatus according to the present invention will be described with reference to the drawings. Such as figure 1 As shown, the trichlorosilane manufacturing apparatus 100 of the first embodiment includes: a reaction vessel 10, a supply gas containing silicon tetrachloride and hydrogen is supplied inside, and a reaction product gas of trichlorosilane and hydrogen chloride is generated by a conversion reaction; The device 20 is arranged around the reaction vessel 10 and heats the reaction vessel 10 from the outside; the gas supply pipe 30 supplies the supply gas into the reaction vessel 10; the gas outlet pipe 32 leads the reaction product gas from the reaction vessel 10 to the outside; A material 34 covers the reaction vessel 10 and the heater 20; a storage container 36 accommodates the reaction vessel 10, the heater 20 and the heat insulating material 34;

[0024] The components constituting the reaction vessel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com