Method and apparatus for delivery of a fuel and combustion air mixture to a gas turbine engine

a gas turbine engine and combustion air technology, applied in the direction of engine ignition, lighting and heating apparatus, engine/propulsion engine, etc., can solve the problems of reducing the emissions performance of the gas turbine engine, overheating/or the combustor premixing section, etc., to achieve the effect of reducing the emissions of co and hc, and reducing the emissions of the engin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

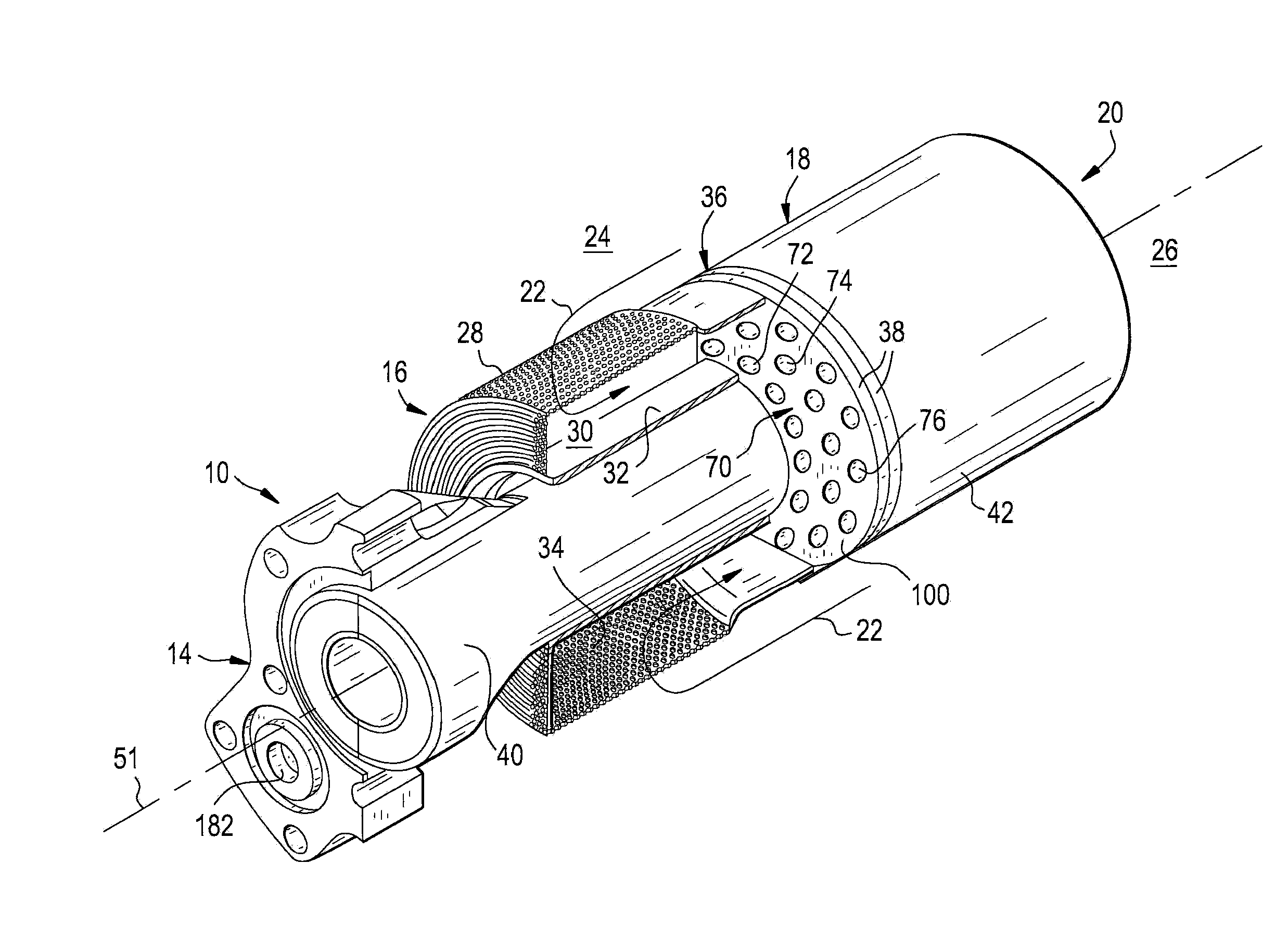

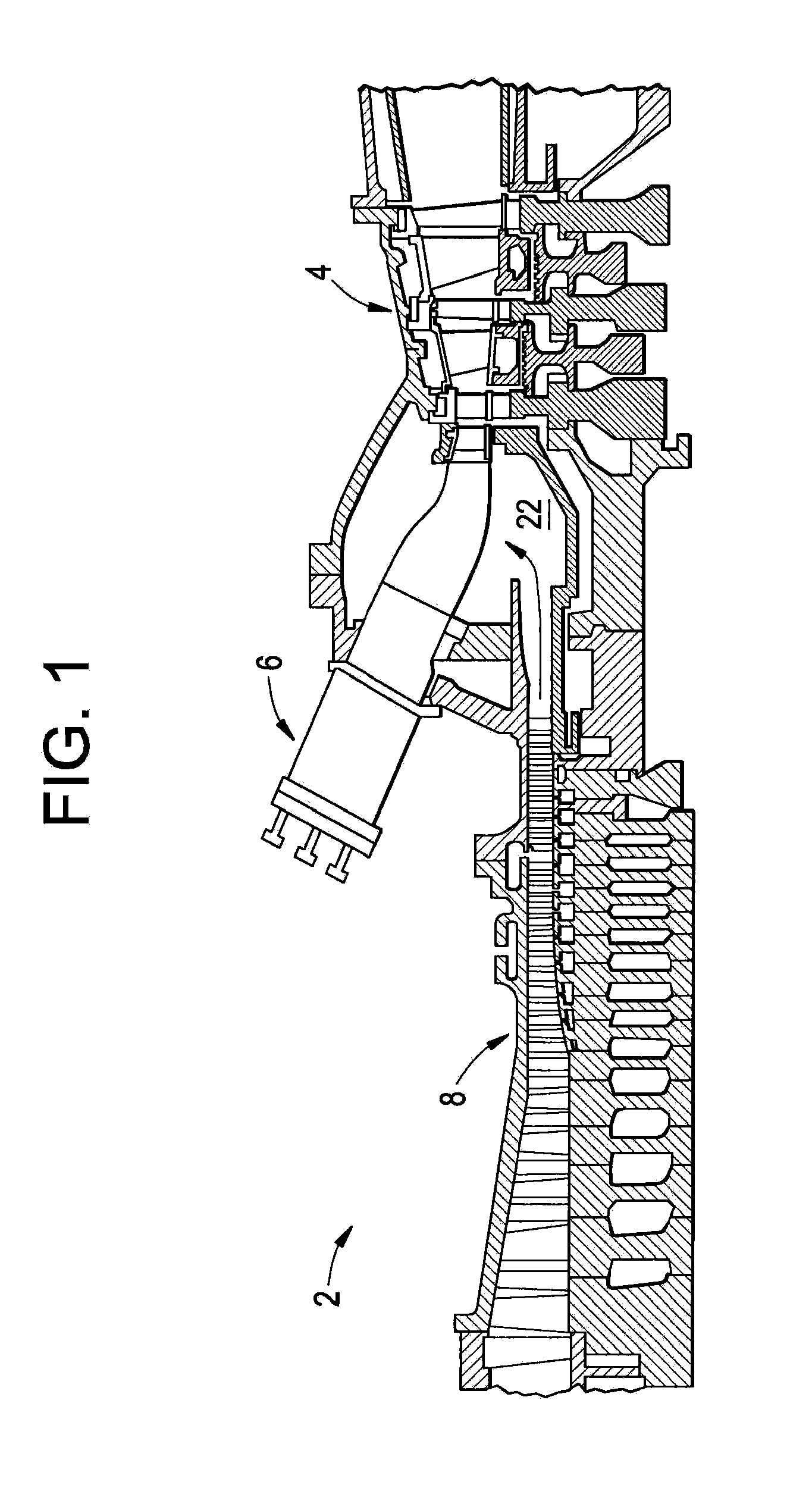

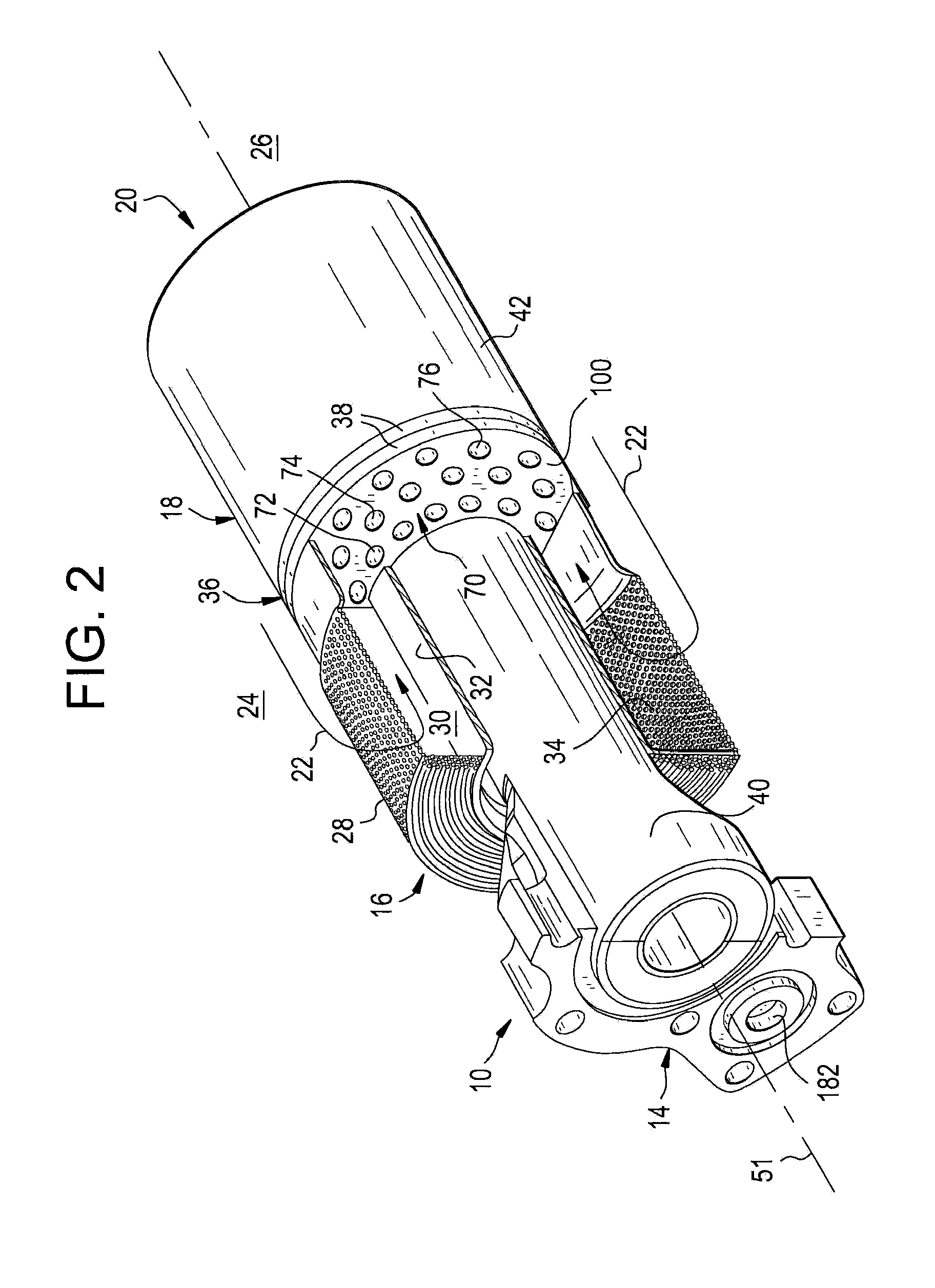

[0019]In one, non-limiting embodiment of the invention shown in FIGS. 1 and 2, a gas turbine engine 2 comprises a turbine 4, a combustor 6 and a compressor 8 for delivery of compressed combustion air 22 to the combustor. The combustor 6 combusts fuel with the combustion air to deliver hot combustion gas through an outlet to the turbine 4.

[0020]A burner assembly 10 for installation in to the combustor 6 of a gas turbine engine 2 is shown. The burner assembly 10 comprises four primary sections, by function, including a fuel inlet and distribution manifold assembly 14, an air inlet and flow conditioner assembly 16, a fuel nozzle assembly 18 and an outlet zone 20. Combustion air 22 enters the burner assembly from a high-pressure plenum 24 surrounding the entire assembly, with the exception of the outlet zone 20 that is disposed within the combustor reaction zone 26 of the combustor 6. The combustion air 22 for the burner assembly 10 enters the air inlet and flow conditioner assembly 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com