Repairing process for coating damage of three-layer polyolefin coating exposed base material

A polyolefin and coating technology, which is applied in coatings, devices for coating liquids on surfaces, pretreatment of surfaces, etc., can solve problems such as waste of costs and resources, and damage to exposed substrates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

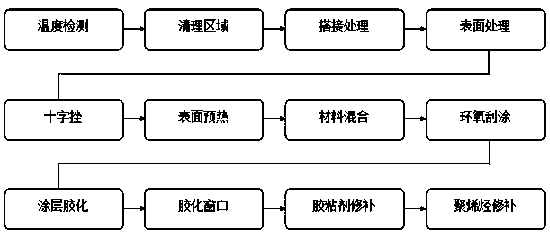

[0031] see figure 1 , embodiment 1 discloses a kind of repairing process of the coating damage of three-layer polyethylene coating exposed base material. As shown in the figure: it includes the following steps:

[0032] a) Temperature and humidity control. Measure the surface temperature of the substrate, ambient temperature, and relative humidity and calculate the dew point temperature. It is carried out when the surface temperature of the substrate is 3°C higher than the dew point temperature. If the surface is lower than 10°C, it should be preheated before repairing. If the surface temperature of the substrate is 3°C lower than the dew point temperature, there may be condensed water on the substrate and other conditions that are not conducive to repairing. If the surface of the substrate is lower than 10°C, the curing of the repair material and the bonding force with the substrate will be adversely affected. .

[0033] b) Preliminary cleaning of the damaged area. Clean ...

Embodiment 2

[0045] Embodiment 2 discloses a repairing process for coating damage of a three-layer polypropylene coating exposed substrate. It includes the following steps:

[0046]A) Temperature and humidity control. Measure the surface temperature of the substrate, ambient temperature, and relative humidity and calculate the dew point temperature. It is carried out when the surface temperature of the substrate is 3°C higher than the dew point temperature. If the surface is lower than 10°C, it should be preheated before repairing. If the surface temperature of the substrate is 3°C lower than the dew point temperature, there may be condensed water on the substrate and other conditions that are not conducive to repairing. If the surface of the substrate is lower than 10°C, the curing of the repair material and the bonding force with the substrate will be adversely affected. .

[0047] B) Initial cleaning of the damaged area. Clean and remove the damaged polypropylene coating in the defec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com