Construction process of rebuilding durable waterproof layer through space displacement method

A technology of construction technology and replacement method, which is applied in the direction of building structure, building maintenance, construction, etc., can solve the problems of secondary leakage of new waterproof layer, difficulty in combining new and old waterproof layers, and non-compliance with environmental protection policies, so as to reduce consumables , save manpower, solve the effect of leakage and water channeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

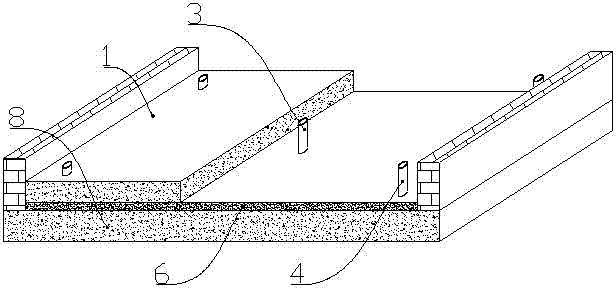

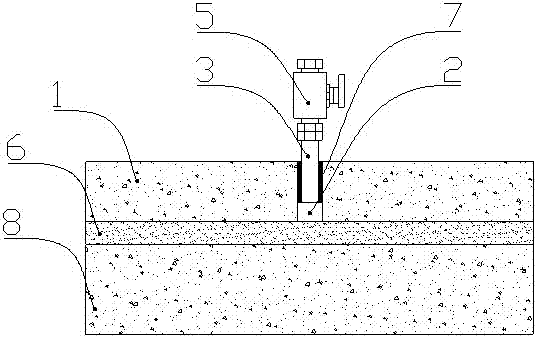

[0034] like Figure 1-2 As shown, a construction technique for recreating a durable waterproof layer using the space replacement method includes the following steps:

[0035] 1) Construction preparation, dealing with 1 defect on the construction surface;

[0036] 2) Drilling, drill a grouting hole 2 at the center of the construction surface 1, and embed a grouting hollow needle 3 in the grouting hole 2, and then drill 1 grouting hole at each of the four corners of the construction surface 1. grouting holes 2, and embed 4 overflow hollow needles 4 in these 4 grouting holes;

[0037] 3) The upper ends of the grouting hollow needle 3 and the overflow hollow needle 4 in step 2) are connected to the feed valve 5;

[0038] 4) Connect the electric injector to the other end of the feed valve 5 on the grouting hollow needle 3, and inject epoxy acrylate into the grouting hole 2 as a back filler;

[0039] 5) Remove the electric injection machine in step 4), connect a waterproof inject...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com