Drilling-and-backfilling type circular mould drilling equipment

A technology of drilling equipment and ring die, which is used in drilling/drilling equipment, boring/drilling, metal processing equipment, etc., and can solve the problems of difficult cleaning and falling in.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

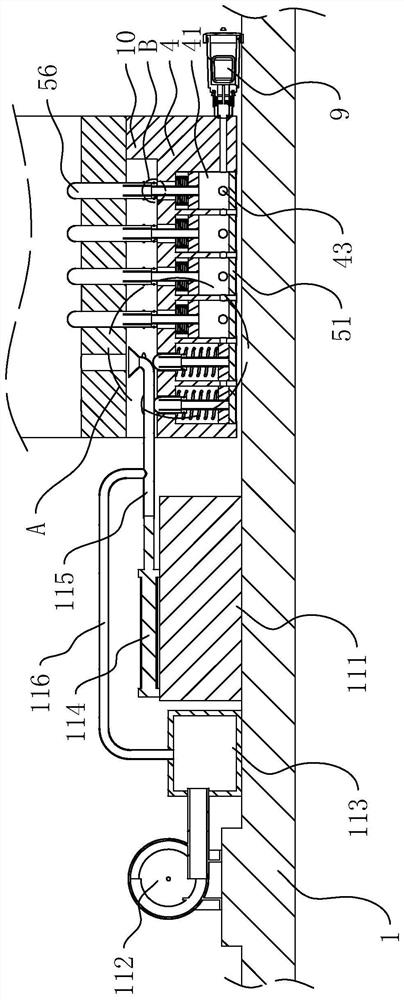

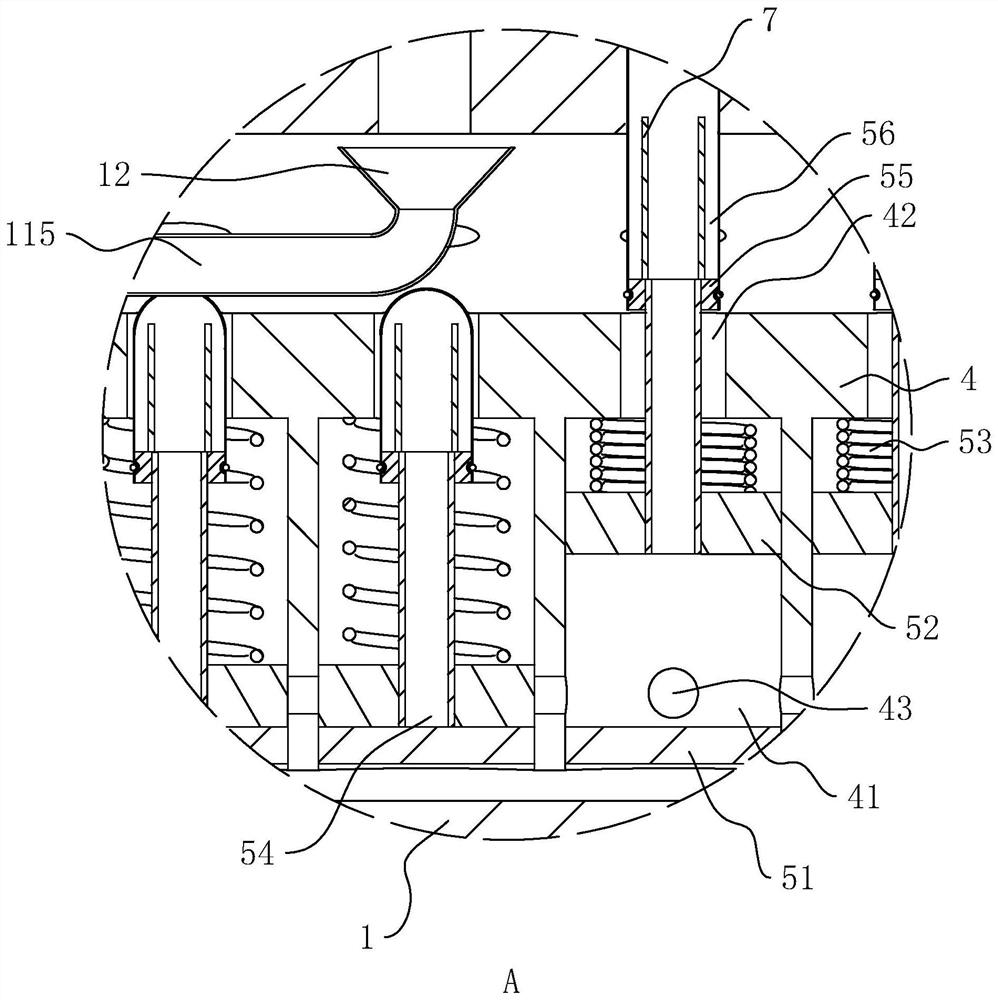

[0035] The following is attached Figure 1-5 The application is described in further detail.

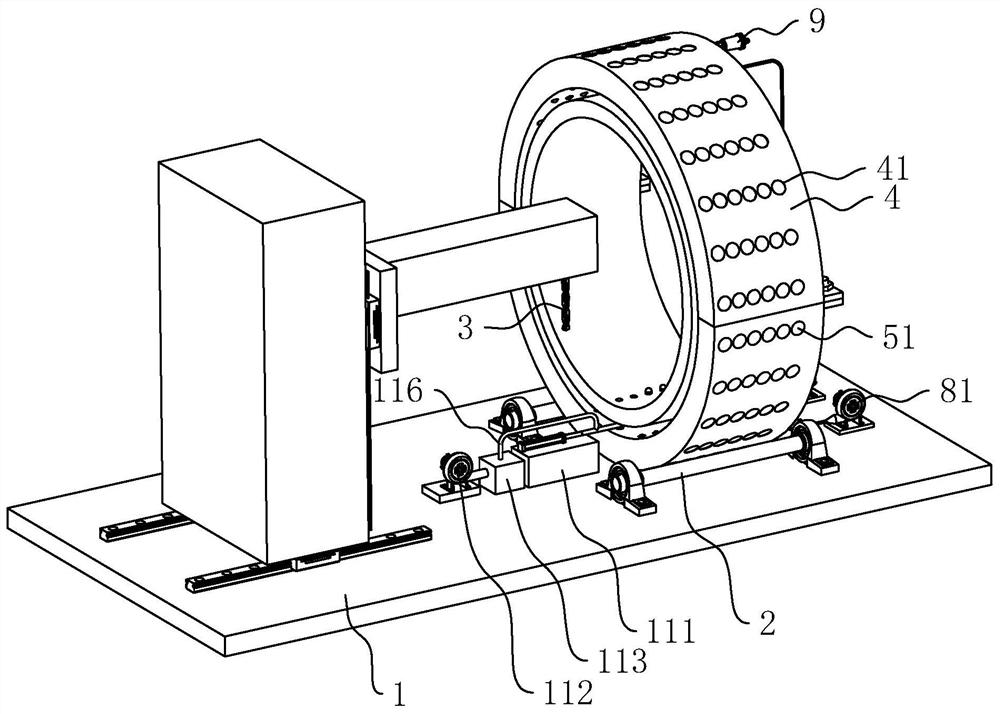

[0036] The embodiment of the present application discloses a drill-and-refill type ring die drilling equipment. refer to figure 1 , The drill and backfill ring die drilling equipment includes a base 1, on which a ring die roller frame 2 is arranged, and a drilling machine 3 is also arranged on the base 1, and the drilling machine 3 is electrically connected to a control system.

[0037] refer to figure 1 and figure 2 , the drill and backfill ring die drilling equipment also includes two semicircular clamp rings 4 that are bolted to each other, the ring die is clamped between the two clamp rings 4, and the clamp ring 4 is placed on the ring die roller frame 2 on.

[0038] Since the ring die roller stand 2 can drive the two clamp rings 4 to rotate synchronously, the bolted joints of the two clamp rings 4 are located on the axial side walls of the clamp rings 4 .

[0039] After t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com