A water-based chromatographic resin anodized aluminum production line and its production process

An electrochemical aluminum and production line technology, applied in the field of bronzing foil, can solve problems such as affecting production efficiency, achieve the effects of reducing waste, improving production economic benefits and production efficiency, and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The following is attached Figure 1-8 The application is described in further detail.

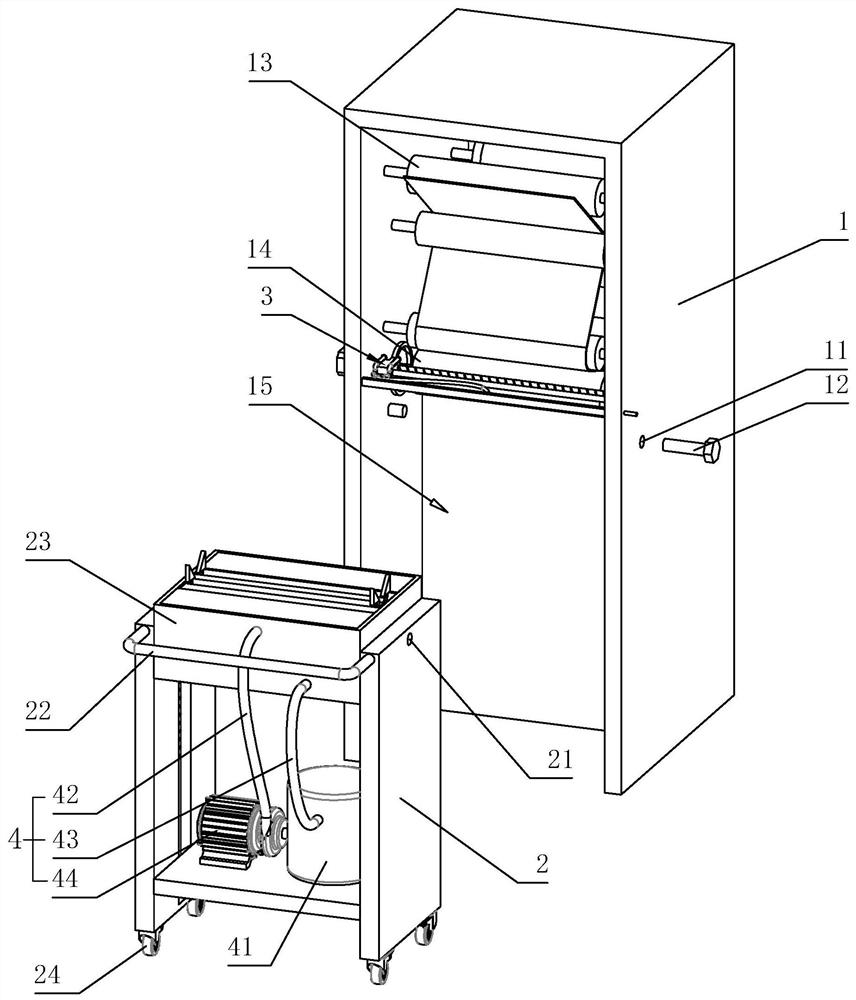

[0043] The embodiment of the present application discloses a water-based chromatographic resin anodized aluminum production line, referring to figure 1 , including a coating machine, the coating machine includes a frame 1 and a mobile transfer frame 2 detachably connected to the frame 1 . The frame 1 is provided with a corresponding gap 15, the frame 1 is provided with a first positioning pin hole 11, and the mobile transfer frame 2 is provided with a second positioning pin hole 21, and the latch 12 is passed through the first positioning pin hole 11 and the second positioning pin hole 11. The positioning pin hole 21 realizes the detachable connection between the frame 1 and the mobile transfer frame 2 .

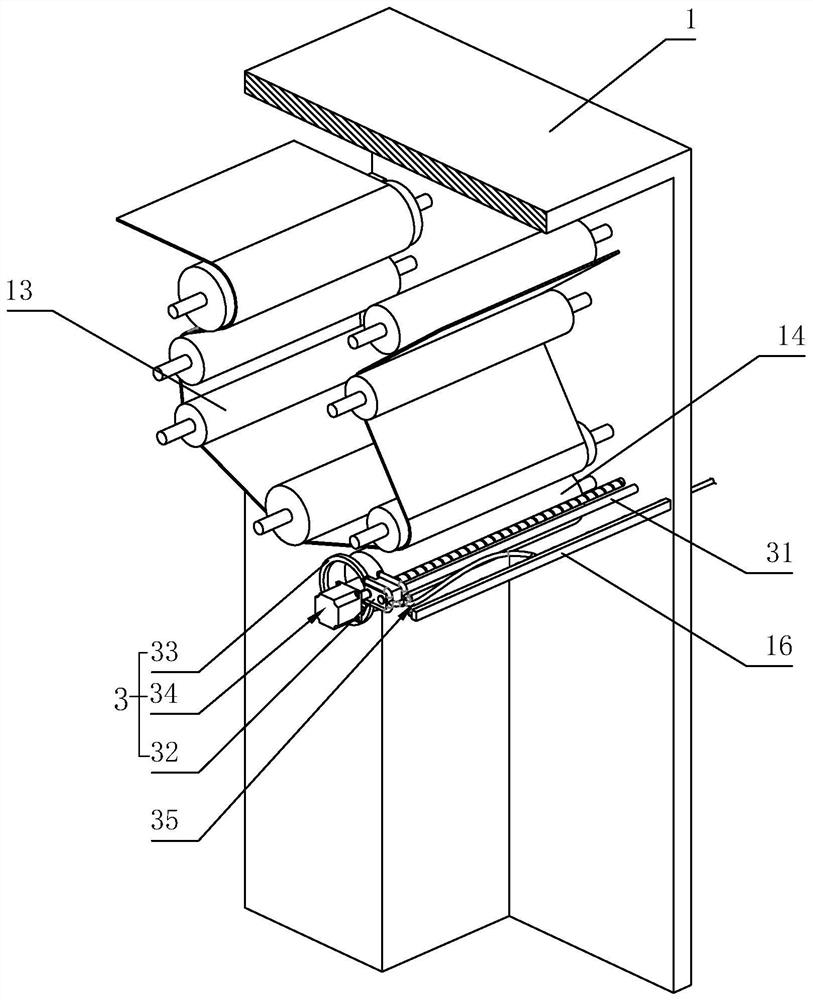

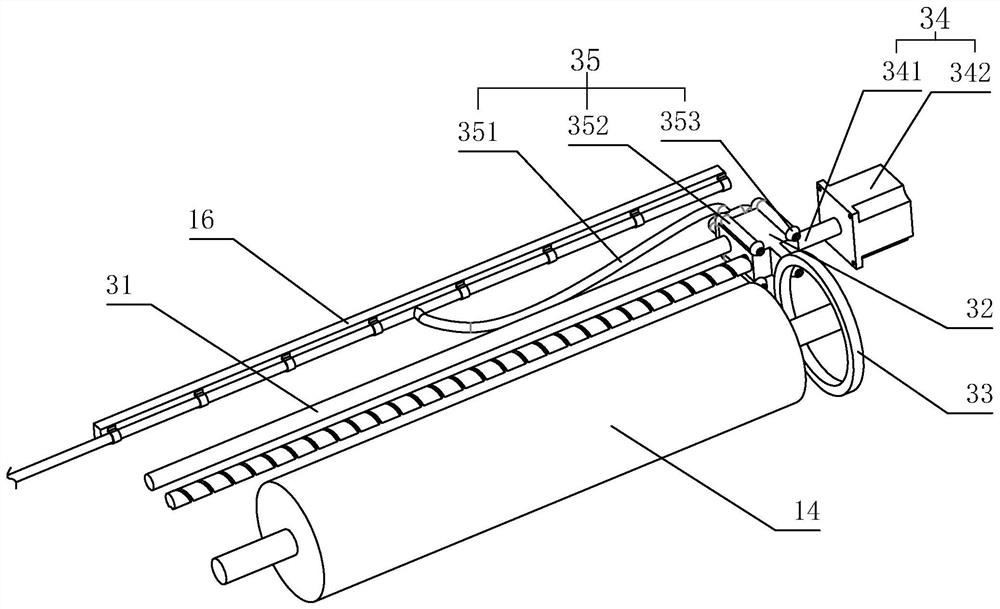

[0044] refer to figure 2 , image 3 The frame 1 is rotatably connected with several transfer rollers 13 for transporting the anodized aluminum film and printing transfer rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com