Self-lubricating bearing copper mesh and manufacturing method thereof

A self-lubricating bearing and copper mesh technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as poor lubrication effect and easily damaged bearings, and achieve excellent lubrication effect and long-lasting reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

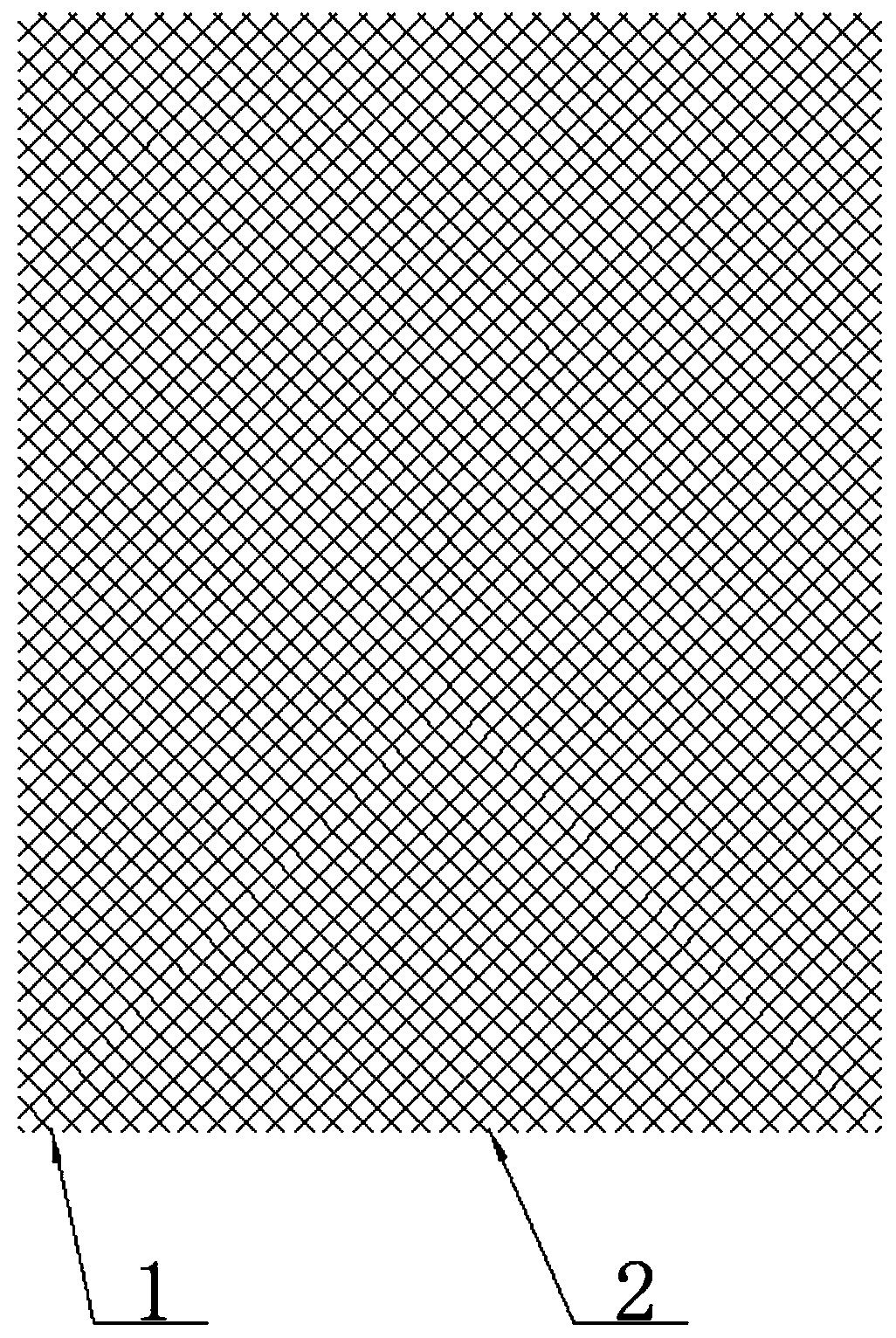

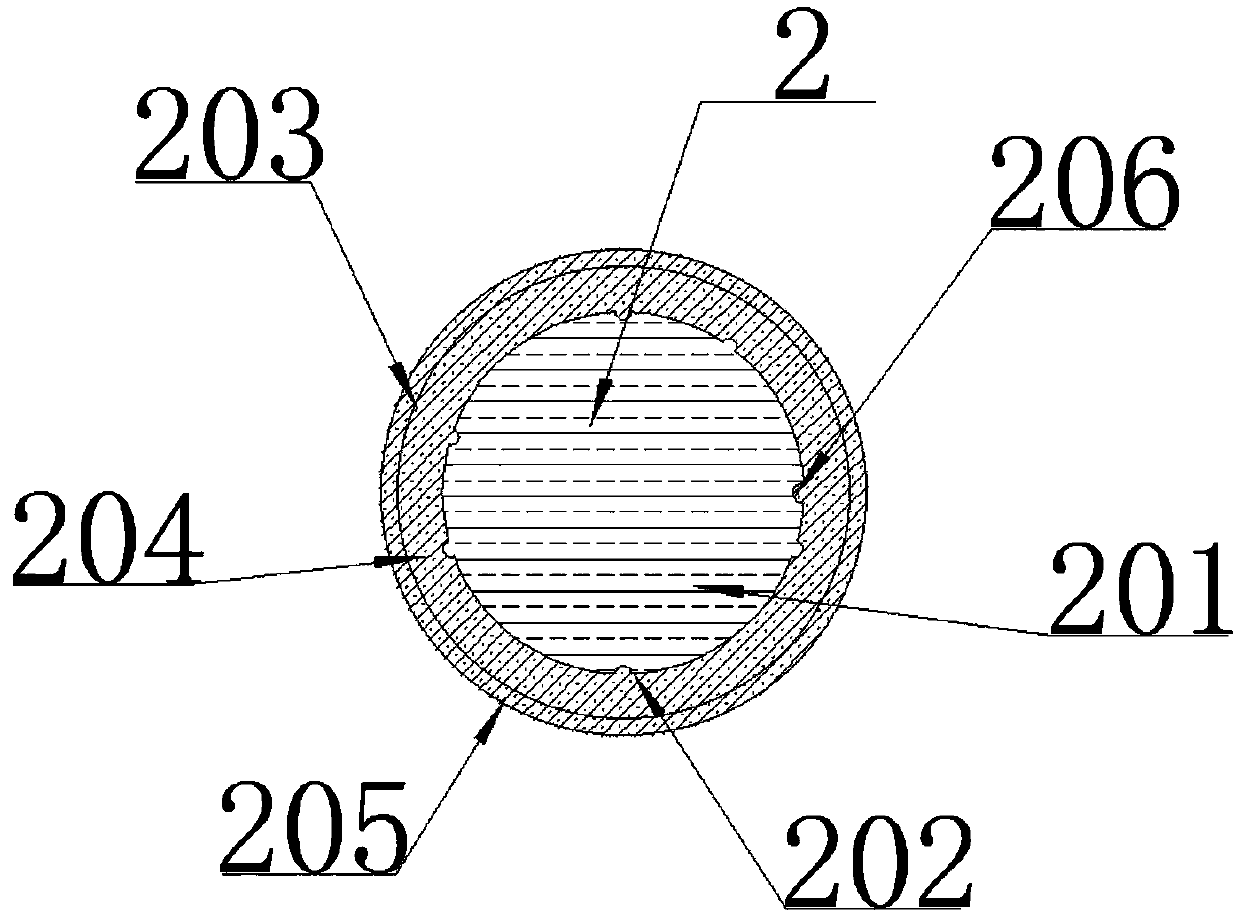

[0028] Such as Figure 1-2 As mentioned above, it is a self-lubricating bearing copper mesh, which includes a number of copper wires 2 cross-woven by latitude and longitude, and the edges of the copper mesh 1 made of copper wires 2 are wrapped with rubber materials. The copper wire 2 includes a copper wire body 201, The outer surface of the copper wire body 201 is extruded by external force to form a concave-convex attachment surface 202 , and the outer surface of the copper wire body 201 is provided with a spiral groove 206 along the length direction of the copper wire body 201 . The spiral groove 206 can make the graphite layer 203 cover on the surface of the copper wire body 201, and at the same time ensure that the graphite layer 203 is filled in the spiral groove 206, so that the copper wire body 201 is provided with a graphite layer 203 in the circumferential direction to ensure stable lubrication and good adhesion. A wear-resistant and lubricating graphite layer 203 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com