Planter and method of operating a planter with individual meter control

A technology of seed metering and seeding machine, which is applied in the directions of seeding machine, seeder parts, agricultural machinery and implements, etc., can solve problems such as waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

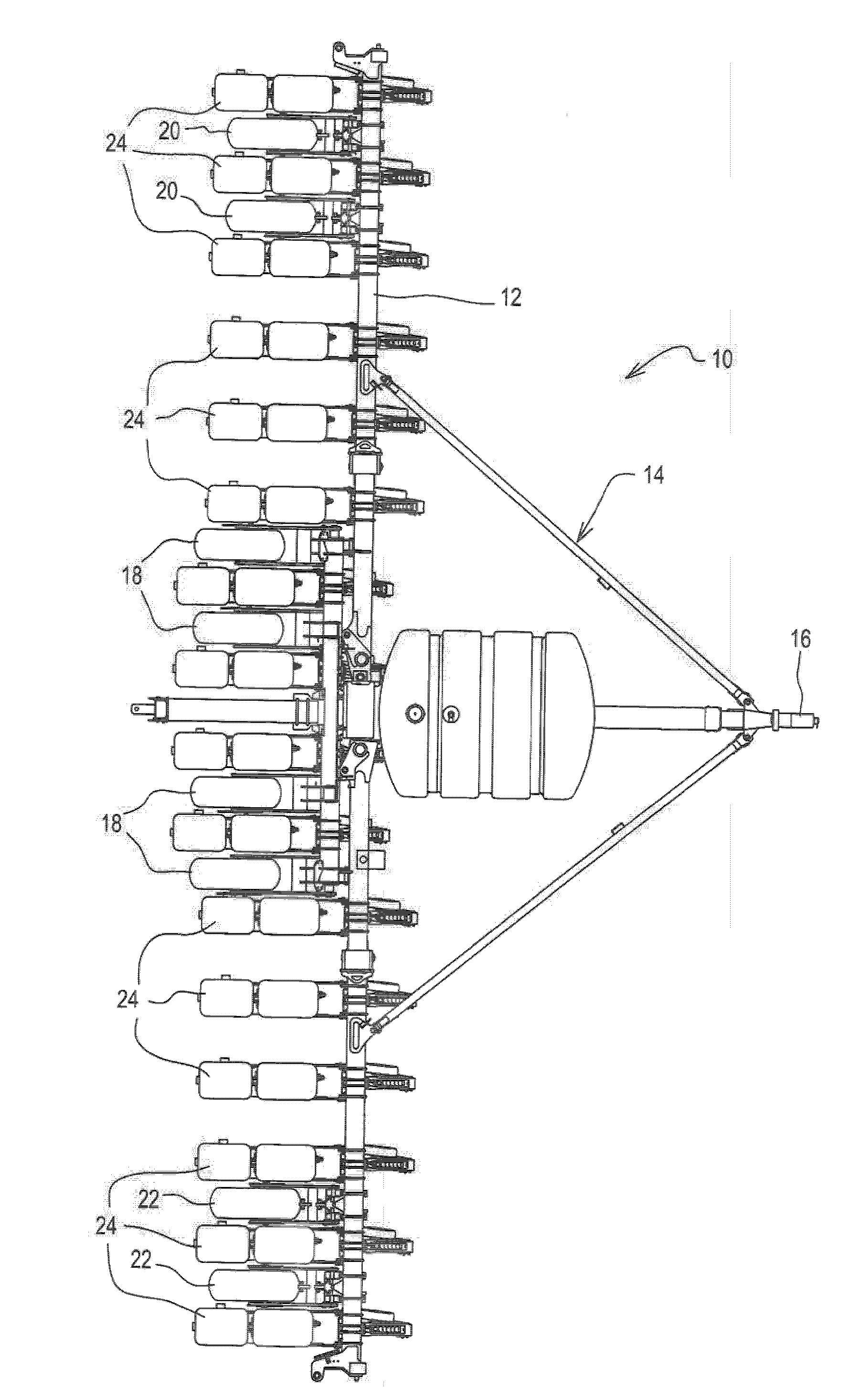

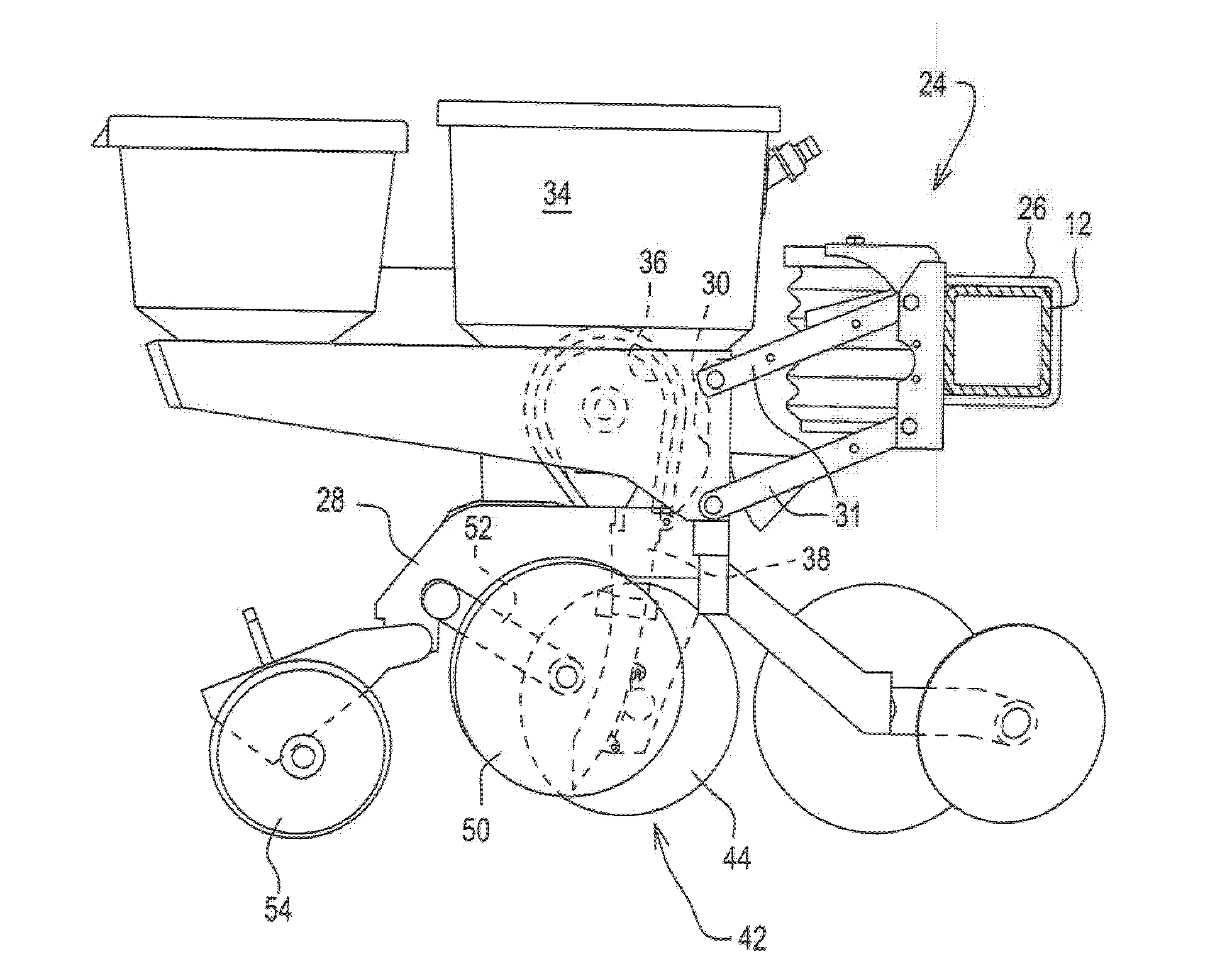

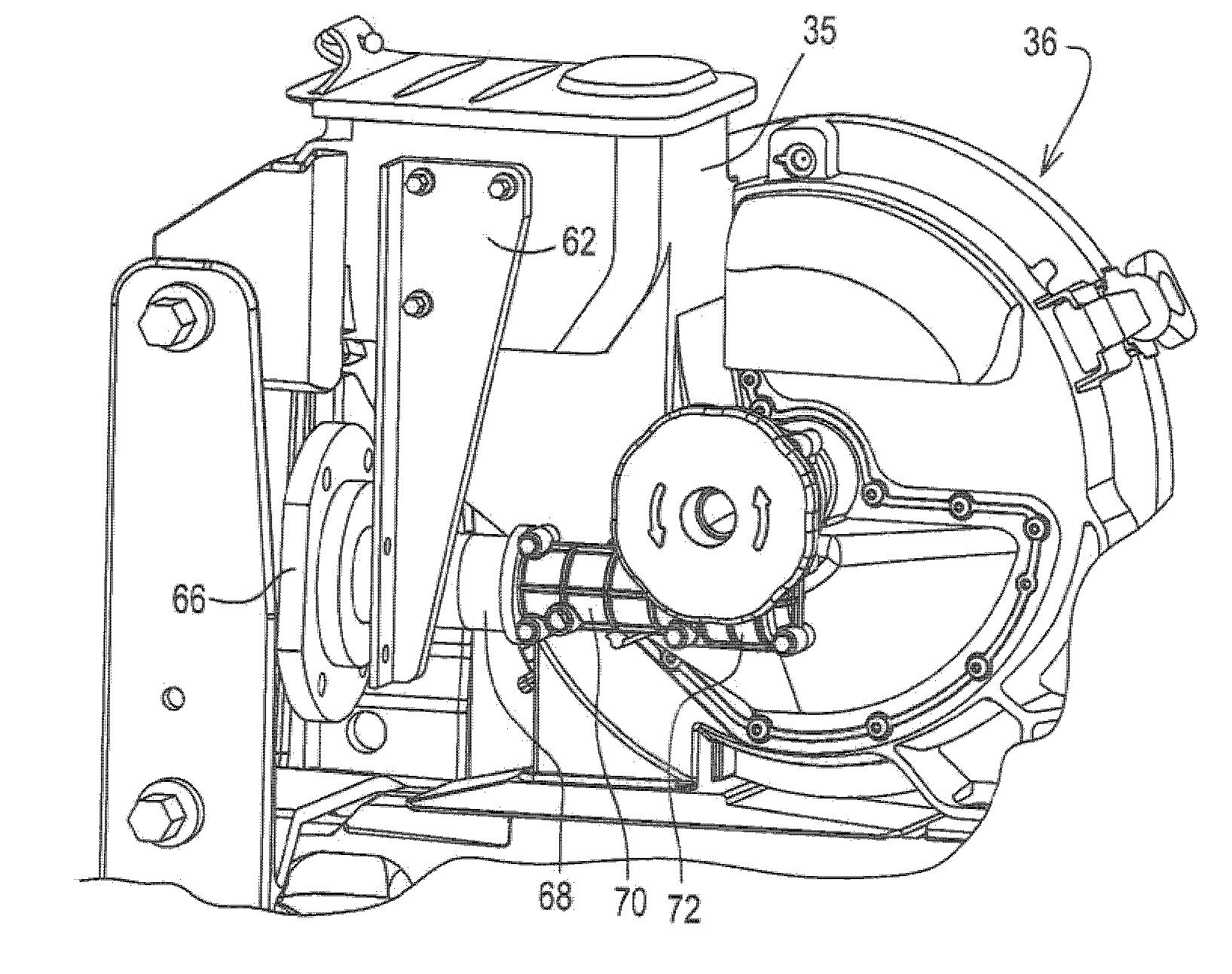

[0016] refer to figure 1 , the planting machine is shown in the form of a row crop planter 10 . The drill 10 includes an implement frame 12 that is part of a drill frame 14 . The frame includes a tongue 18 by which the planter is connected to a tractor (not shown). Three sets of ground engaging wheels support the planter frame 14 . The center set has four wheels 18 , while the left set has two wheels 20 and the right set has two wheels 22 . A plurality of planter row units 24 are mounted to the implement frame. for a given seeder. Row cells 24 are typically, but need not be, identical. exist figure 2 The row unit 24 is shown in more detail in . Row unit 24 is mounted to implement frame 12 by U-bolts 26 . The row unit 24 is provided with a central frame member 28 having a pair of upwardly extending arms 30 at its front end. The arm 30 is connected to a parallel link 31 for mounting the row unit 24 to the implement frame 12 for relative movement up and down between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com