A kind of high-strength direct-plating aluminum water-based primer and its preparation method and application

A high-strength, water-based technology, applied in coatings, paper coatings, metal coatings, etc., to achieve high flexibility, improve flexibility, and increase cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

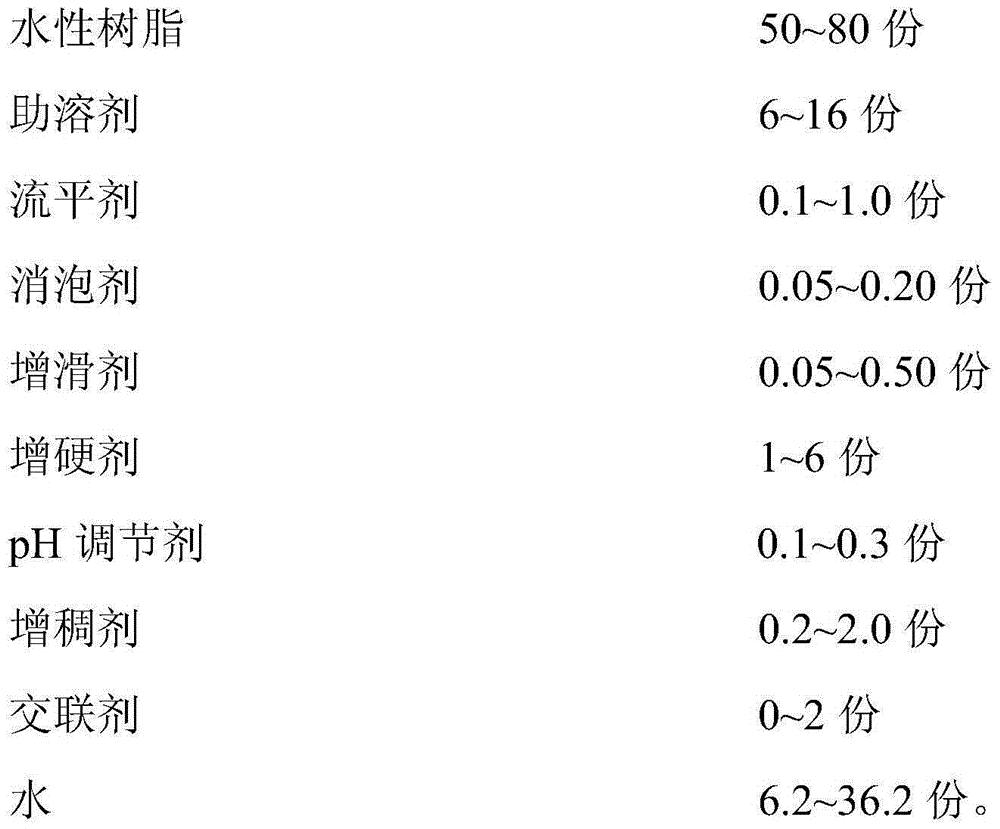

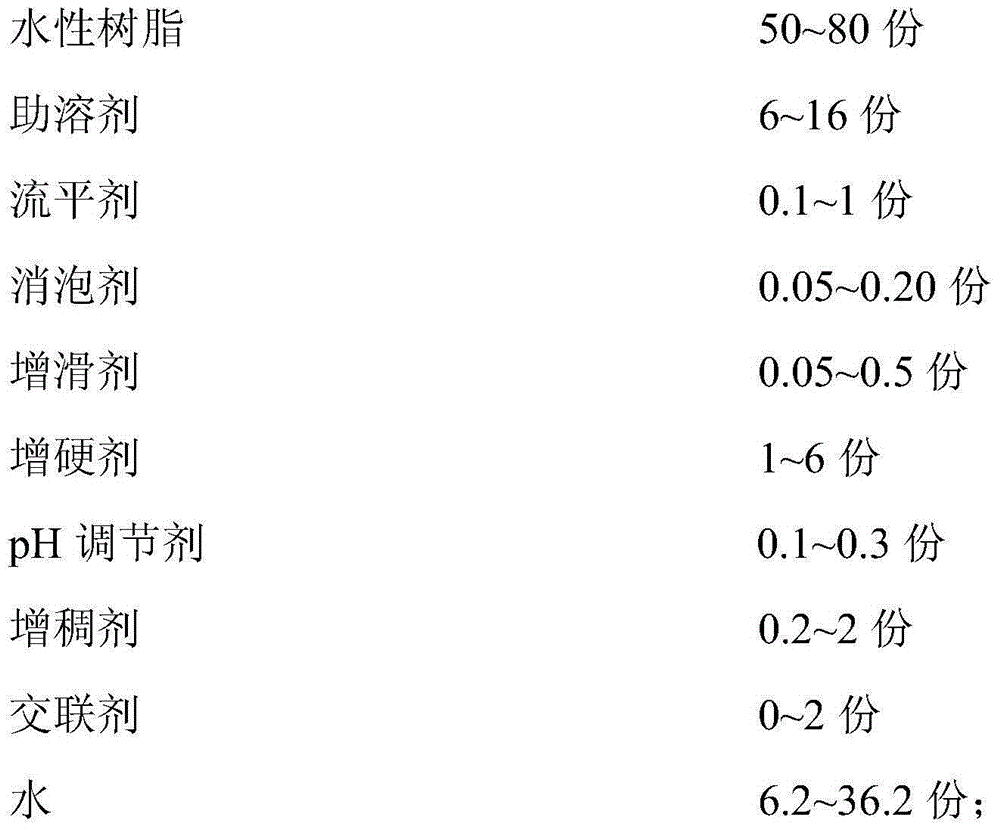

Method used

Image

Examples

Embodiment 1

[0043] (1) Preparation of water-based primer for direct aluminum plating:

[0044] (1) Mix 2g propylene glycol methyl ether and 6g ethanol evenly, then add 0.5g leveling agent BYK333 (polyether modified organosiloxane), 0.2g slip agent silok-8580 (silicon-containing organic compound) and 0.05g Defoamer tego902W (polyether modified organosiloxane), stir (200-1000r / min) until each component is dissolved, add 36.15g of deionized water and stir (200-1000r / min) evenly to obtain a mixed solution;

[0045] (2) Add 50g of DSM water-based acrylic modified polyurethane E-129 (solid content 60%) to the mixed solution obtained in step (1) under low-speed stirring (200-1000r / min), and then add 2g of water-based aldehyde ketone EPDS- 1300, dispersed evenly; then about 0.1g cyclohexylamine was added dropwise to adjust the pH to 6-9 to obtain a solution;

[0046] (3) Add 1g of thickener Dow hydroxyethyl cellulose ER-4400 (1% (mass) aqueous solution) to the solution obtained in step (2), adju...

Embodiment 2

[0050] (1) Preparation of water-based primer for direct aluminum plating:

[0051] (1) Mix 4g propylene glycol methyl ether acetate, 6g ethanol, and 6g n-propanol evenly, add 0.1g leveling agent EFKA-3777 (fluorocarbon leveling agent), 0.3g slip agent DC-30 (containing silicon organic compound) and 0.05g mineral oil defoamer AD-76, stir (200-1000r / min) until each component is dissolved, then add 19.35g deionized water and stir (200-1000r / min) evenly to obtain a mixed solution;

[0052] (2) Add 40g of DSM waterborne polyurethane NeoRezR-986 (solid content 34% (mass)) and 16g of waterborne polyester EW-312 ( 50% (mass)), then add 5g organic hardening resin water-based acrylic acid AC-830 (35% (mass)), and disperse evenly; then add about 0.2g N,N-dimethyldiethanolamine dropwise to adjust the pH to 6-9 , to obtain a solution;

[0053] (3) Add 1g of acrylic thickener LH-122 to the solution obtained in step (2) to adjust the viscosity to 25±2ss; then add 2g of silane coupling agen...

Embodiment 3

[0057] (1) Preparation of water-based primer for direct aluminum plating:

[0058] (1) Mix 3g propylene glycol methyl ether, 1g n-butanol and 6g ethanol evenly, add 1g leveling agent Deqian levelol839 (acrylate leveling agent), 0.05g slipping agent CHEMIPEARLW900 (Mitsui Chemicals, water-based polyolefin wax emulsion) and 0.1g of antifoaming agent tego835 (polydimethylsiloxane defoaming agent), stirring (200-1000r / min) until each component is dissolved, then adding 15.8g of deionized water and stirring (200-1000r / min) Uniformly, a mixed solution is obtained;

[0059] (2) Add 40g of Bayer water-based polyurethane 2593 (solid content 35% (mass)) and 30g of ADEKA water-based polyurethane HUX1032 (solid content 30% % (mass)), then add 2g of nano-silica aqueous solution (10% (mass)), and disperse evenly; then add about 0.25g of 1-aminoisopropanol dropwise to adjust the pH to 6-9 to obtain a solution;

[0060] (3) Add 0.8g thickener ADEKAUH-450 (polyurethane associative thickener)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com