High-viscosity self-adhesive protection film and preparation method thereof

A self-adhesive protective film, high-viscosity technology, applied in the direction of chemical instruments and methods, flat products, other household appliances, etc., can solve the problems of adhesive layer sticking roller, poor unwinding force, rewinding foaming, etc., to achieve easy solution Effect of roll, easy unwinding, good tack stability and aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

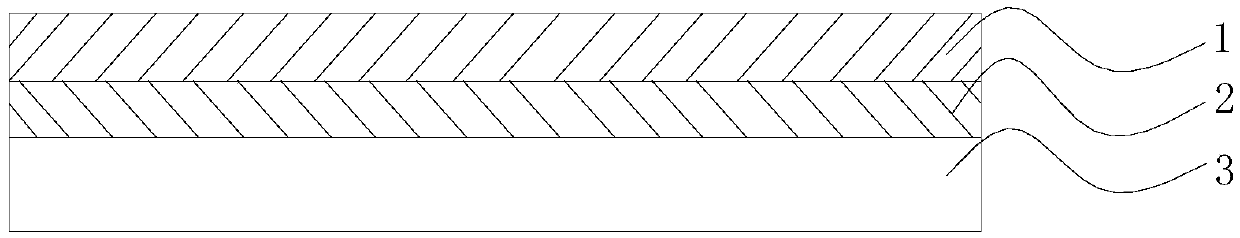

[0032] A high-adhesive self-adhesive protective film, which includes a self-adhesive layer 1, an intermediate layer 2 and a release back layer 3 from top to bottom, and the release back layer 3 is a release back layer added with a release masterbatch, wherein, Self-adhesive layer 1 is prepared by 85% modified SEBS and 15% linear low-density polyethylene by weight percentage; the middle 2 layers are made by 80% linear low-density polyethylene and 20% low-density polyethylene by weight percentage Prepared from polyethylene; the anti-adhesive back layer 3 is prepared by 70% linear low-density polyethylene, 15% low-density polyethylene, and 15% anti-adhesive masterbatch, and the anti-adhesive masterbatch is calculated by weight percentage , made of 85% polypropylene and 15% synthetic silica, the thickness of the self-adhesive layer 1 is 4um, the thickness of the middle layer 2 is 20um, and the thickness of the release back layer 3 is 4um.

Embodiment 2

[0034] A high-adhesive self-adhesive protective film, which includes a self-adhesive layer 1, an intermediate layer 2 and a release back layer 3 from top to bottom, and the release back layer 3 is a release back layer added with a release masterbatch, wherein, The self-adhesive layer 1 is prepared by 90% modified SEBS and 10% linear low density polyethylene by weight percentage; the middle layer 2 is made by 85% linear low density polyethylene and 15% low density polyethylene by weight percentage Prepared from polyethylene; the anti-adhesive back layer 3 is prepared by 65% linear low-density polyethylene, 20% low-density polyethylene, and 15% anti-adhesive masterbatch, and the anti-adhesive masterbatch is calculated by weight percentage , made of 90% polypropylene and 10% synthetic silica, the thickness of the self-adhesive layer 1 is 6um, the thickness of the middle layer 2 is 35um, and the thickness of the release back layer 3 is 6um.

Embodiment 3

[0036]A high-adhesive self-adhesive protective film, which includes a self-adhesive layer 1, an intermediate layer 2 and a release back layer 3 from top to bottom, and the release back layer 3 is a release back layer added with a release masterbatch, wherein, The self-adhesive layer 1 is prepared by 80% modified SEBS and 20% linear low density polyethylene by weight percentage; the middle layer 2 is made by 75% linear low density polyethylene and 25% low density polyethylene by weight percentage Prepared from polyethylene; the anti-adhesive back layer 3 is prepared by 75% linear low-density polyethylene, 10% low-density polyethylene, and 15% anti-adhesive masterbatch, and the anti-adhesive masterbatch is calculated by weight percentage , made of 90% polypropylene and 10% synthetic silica, the thickness of the self-adhesive layer 1 is 8um, the thickness of the middle layer 2 is 50um, and the thickness of the release back layer 3 is 8um.

[0037] In the present invention, by imp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com