Polyelectrolyte film, film-electrode assembly, and solid-polymer-type fuel cell

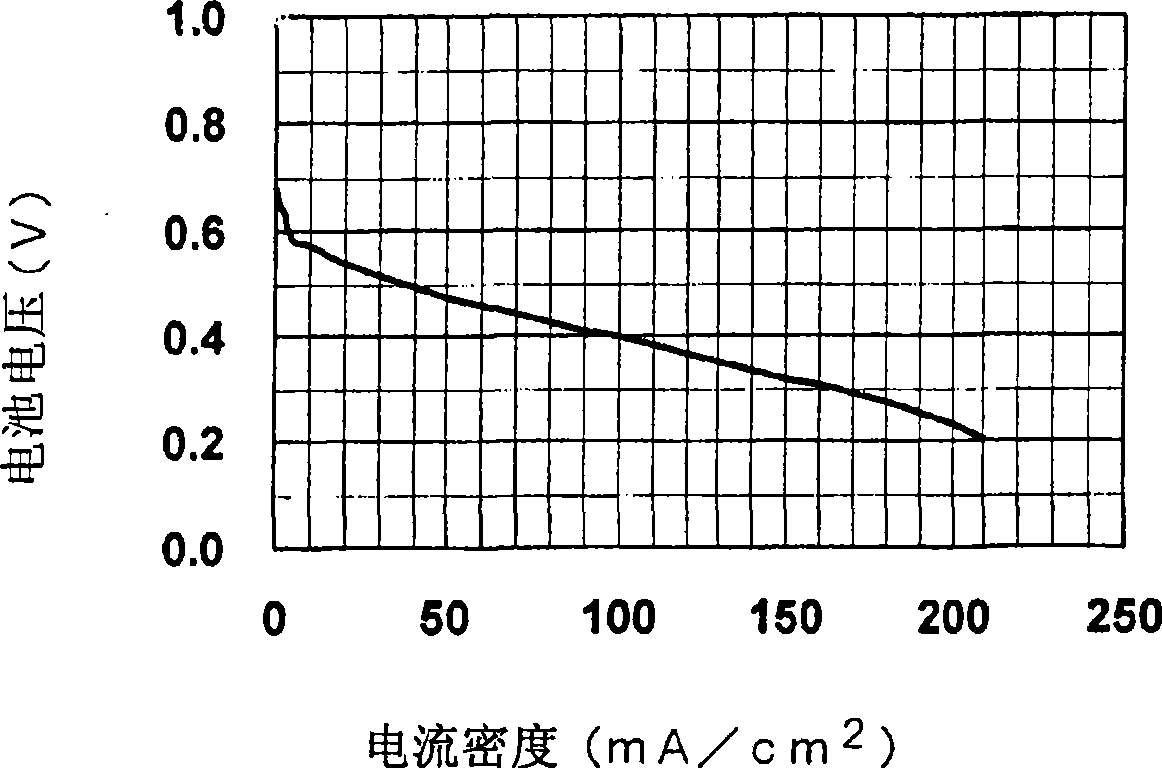

A technology of electrolyte membrane and polymer, applied in the direction of solid electrolyte fuel cells, fuel cell parts, non-metallic conductors, etc., can solve problems such as electrolyte membranes that have not yet been obtained, and achieve good adhesion, high ionic conductivity, excellent performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0053] Embodiment 1 (alkyl substitution)

[0054] This embodiment is such that the above-mentioned basic embodiment is further embodied, and is most characterized in that in the aromatic vinyl compound unit as a unit (= repeating unit) in the polymer block (A) , at least one hydrogen atom directly bonded to the aromatic ring is replaced by an alkyl group having 1 to 8 carbon atoms. The polymer electrolyte membrane including the block copolymer containing the polymer block (A) of Embodiment 1 as a main component is specifically characterized in that it has a low methanol permeability and is excellent in methanol barrier performance.

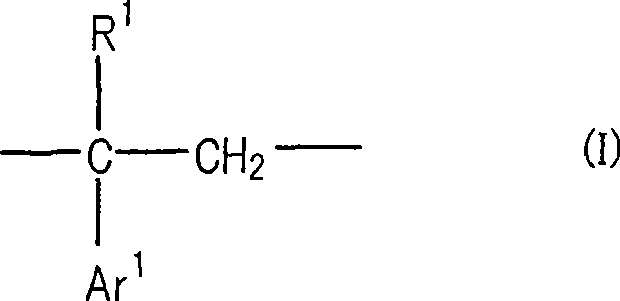

[0055] In this embodiment, the polymer block (A) can be defined as a polymer block (A1) having an aromatic vinyl compound unit represented by the following general formula (I) as a main unit

[0056]

[0057] where Ar 1 represents an aryl group having 6 to 14 carbon atoms substituted by an alkyl group having 1 to 8 carbon atoms and which ma...

Embodiment approach 2

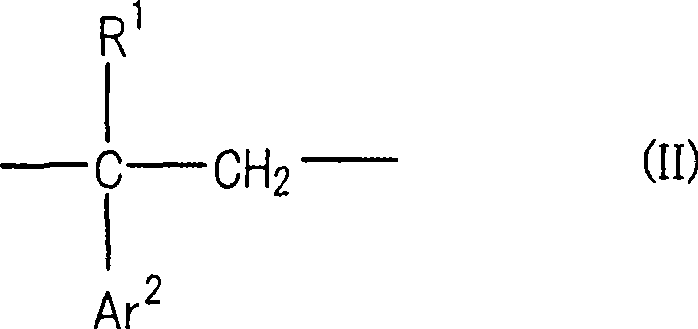

[0071] Embodiment 2 (constraint phase)

[0072] In Embodiment 2 of the present invention, the polymer block (A) has a polymer block (A2b) in addition to the polymer block (A2a) with an ion-conducting group, and the polymer block (A2b ) is a polymer block (A2b1) or a crystalline polyolefin block having an aromatic vinyl compound unit as a main unit, and forms a constrained phase (a phase that functions to maintain the phase-separated structure of the block copolymer). As described in the Background Art section, in a polymer electrolyte fuel cell, a change in humidity easily occurs between an operation period and a stop period, and thus a small change in size and / or a change in dynamic characteristics (tensile strength, etc.) are sought at the same time. A small polymer electrolyte membrane, in addition, in which, in a direct methanol polymer electrolyte fuel cell, characteristics between before and after power generation corresponding to before and after immersion treatment i...

Embodiment approach 3

[0104] Embodiment 3 (crosslinking)

[0105] In this embodiment of the invention, the polymer block (A1) in embodiment 1 is self-crosslinked, and the polymer block (A2a) in embodiment 2 is self-crosslinked. This crosslinking is made intermolecular and / or intramolecular. The polymer electrolyte membrane comprising the block copolymer of the present embodiment as a main component is specifically characterized in that there is little change in characteristics such as methanol permeability and ion conductivity between before and after immersion in a methanol solution, and it can be used over a long period of time. exhibited stable performance over time.

[0106] As means for crosslinking, there are crosslinking methods using polyamines, radical crosslinking methods, etc., and any of them may be used, but since crosslinking is usually performed simultaneously with or after the preparation of the polymer electrolyte membrane , so the crosslinking will be described later in the de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Maximum power density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com