Method for preparing thermoplastic compositions based on plasticized starch and resulting compositions

A composition, technology of thermoplastic starch, applied in the field of composition and thermoplastic starch composition obtained from the latter, able to solve problems such as limited use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

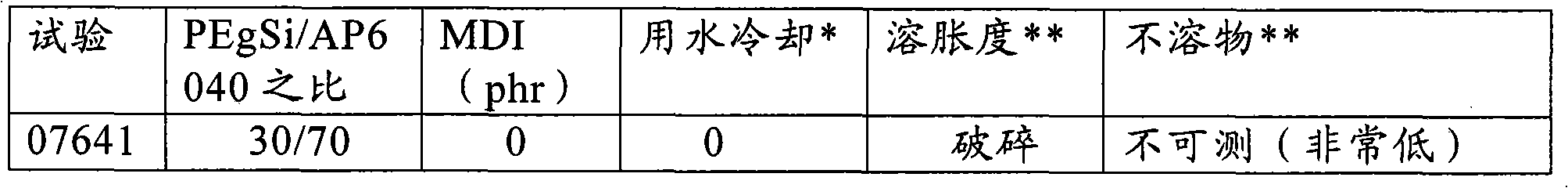

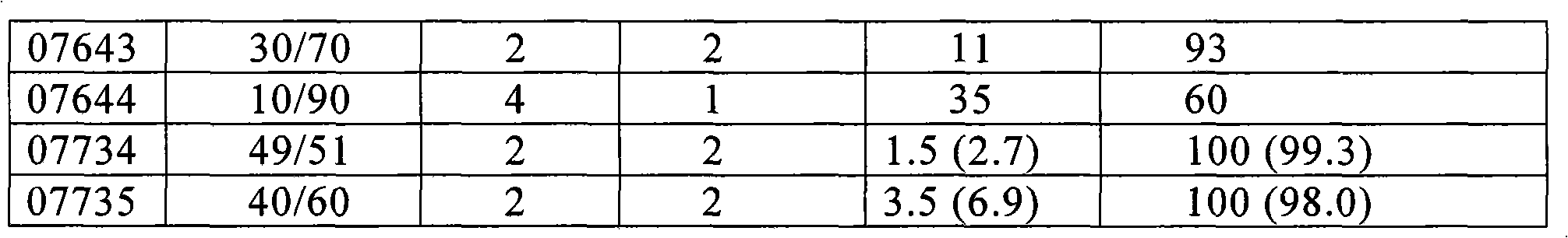

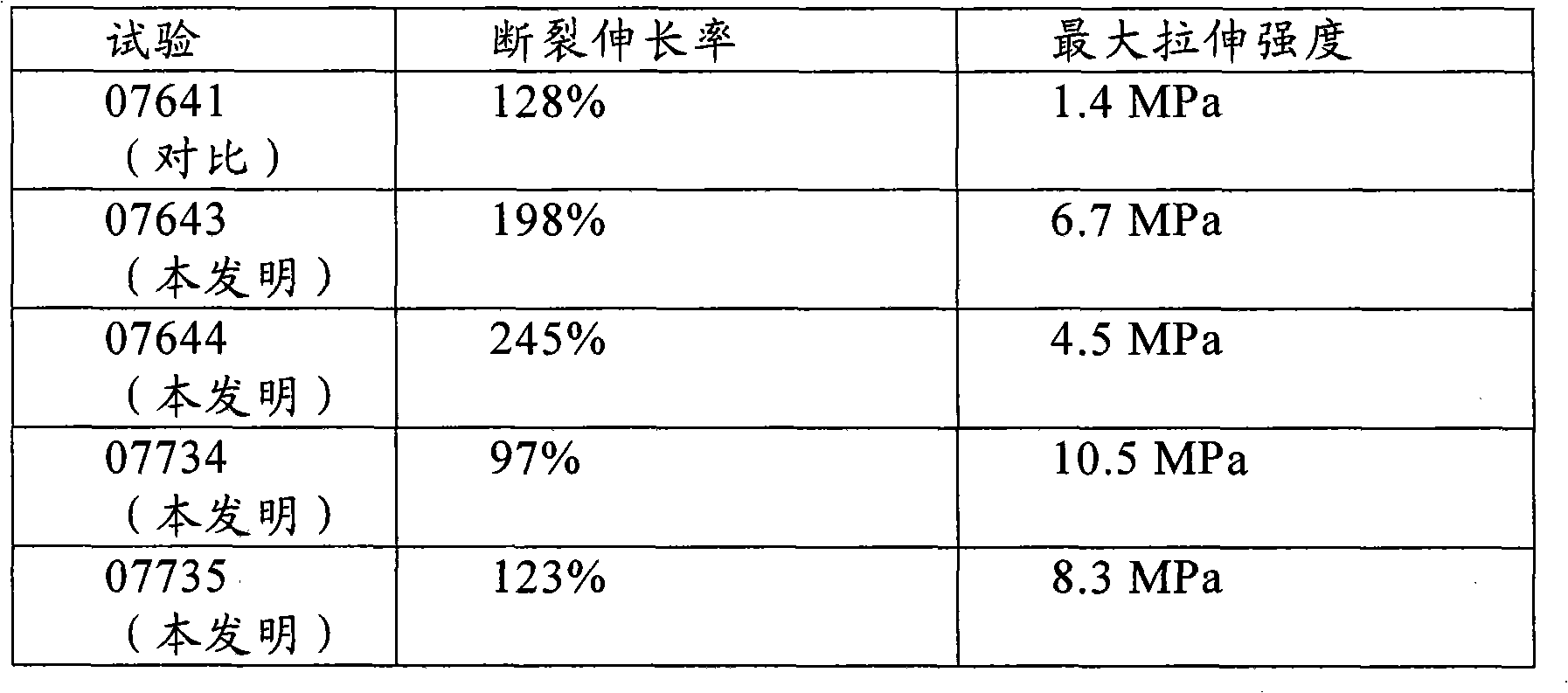

[0164]Compositions according to the prior art and compositions according to the invention obtained with wheat starch, starch plasticizer, silane-grafted PE and coupling agent

[0165] Preparation of the composition:

[0166] The ones used for this instance are:

[0167] - as granular starch, a native wheat starch sold by the applicant under the name "Amidon de blé SP" [Wheat Starch SP], with a moisture content of about 12%;

[0168] - as a plasticizer for granular starch, a concentrated aqueous composition of glycerol-based and sorbitol-based polyols sold by the applicant under the name POLYSORB G84 / 41 / 00, having about 16% of water volume;

[0169] - As non-starch polymer, a polyethylene (PEgSi) grafted with 2% vinyltrimethoxysilane. The PEgSi used was previously obtained by grafting vinyltrimethoxysilane onto a low-density PE by extrusion. As an example of such a commercially available PEgSi, mention may be made of the products BorPEX ME2510 or BorPEX HE2515, both sold b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com