Thermoplastic compositions based on soluble starch and method for preparing such compositions

A thermoplastic composition, a technology for the composition, applied in the field of the composition and the thermoplastic starch composition obtained from the latter, and can solve the problems of limited use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

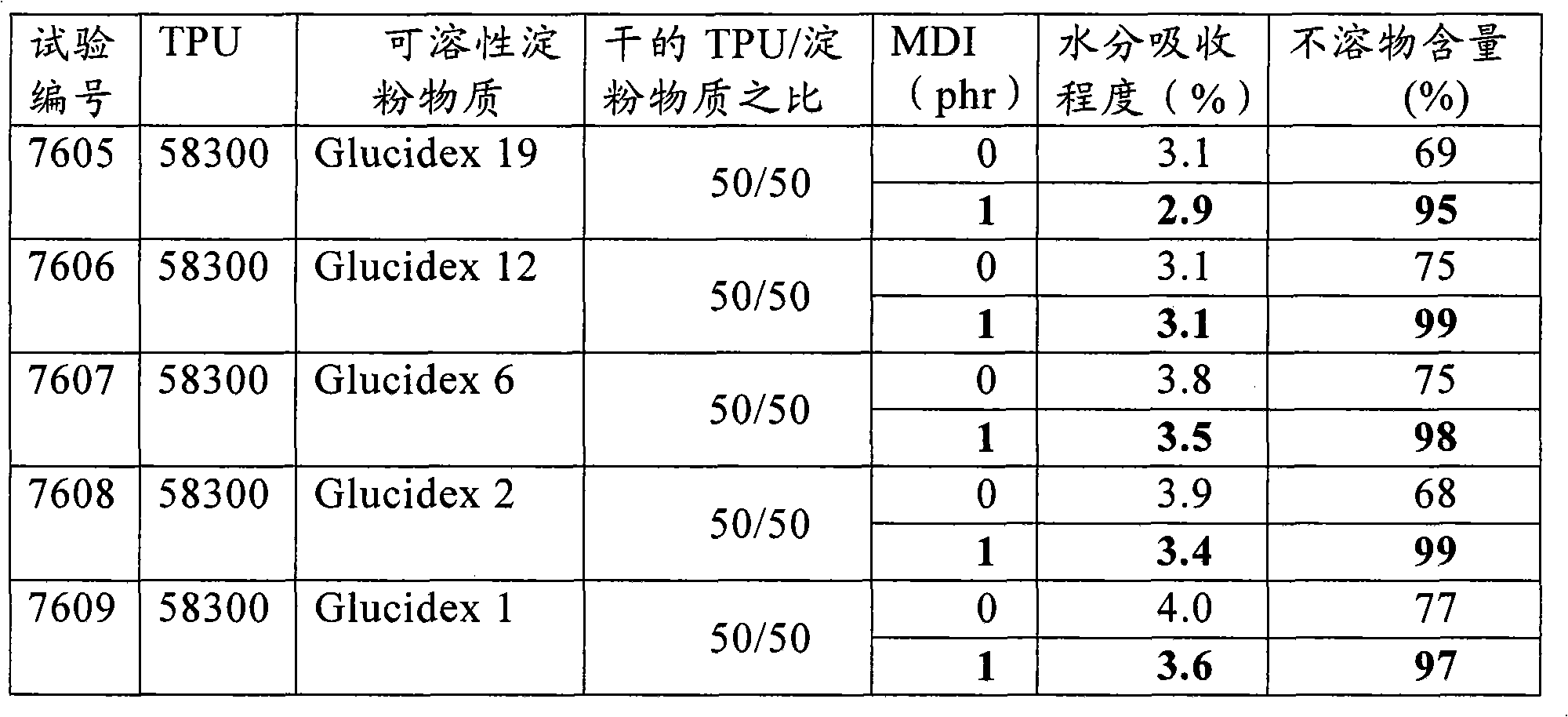

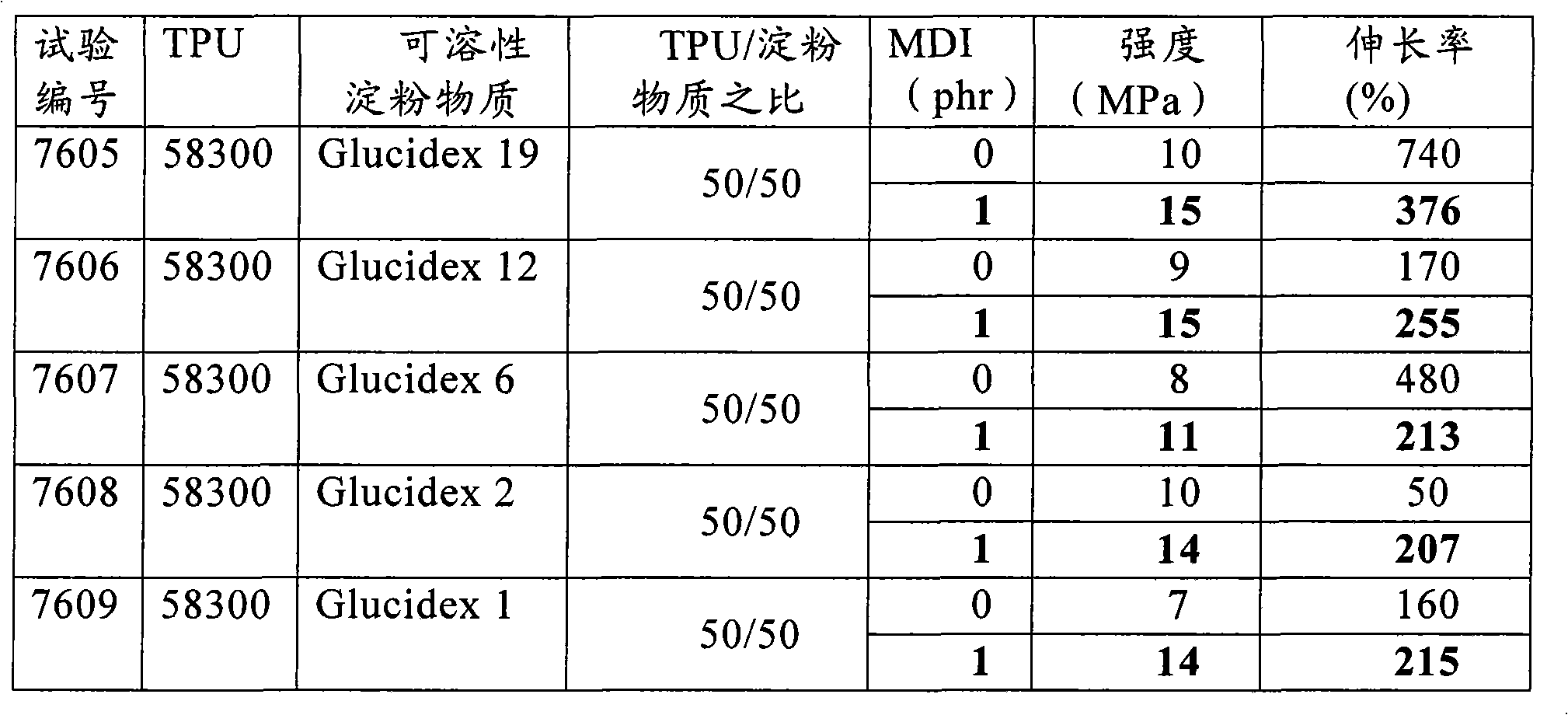

[0156] According to prior art (without coupling agent) and according to the base of the present invention (with coupling agent) Comparison of starch composition with water-soluble maltodextrin

[0157] Used for these instances are:

[0158] - As soluble starches, different maltodextrins sold by the applicant under the names GLUCIDEX 1, GLUCIDEX 2, GLUCIDEX 6, GLUCIDEX 12 and GLUCIDEX 19, with a water content of about 4%. These maltodextrins have a soluble fraction close to 100% in water at 20°C;

[0159] - a thermoplastic polyurethane (TPU) sold under the name ESTANE 58300 by Lubrisol as a non-biodegradable non-starch polymer; and

[0160] - As coupling agent, methylene diphenyl diisocyanate (MDI) sold under the name Suprasec 1400 by Huntsman.

[0161] A TSA brand twin-screw extruder (diameter (D) 26 mm, length 56D) was fed with a 50 / 50 maltodextrin (undried) / TPU mixture at a total throughput of 15 kg / h.

[0162] The extrusion conditions are as follows:

[0163] - tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com