Method for preparing thermoplastic compositions based on plasticized starch and resulting compositions

A thermoplastic composition, the technology of the composition, applied in the field of preparing starch-based thermoplastic composition, can solve the problems of limited use and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

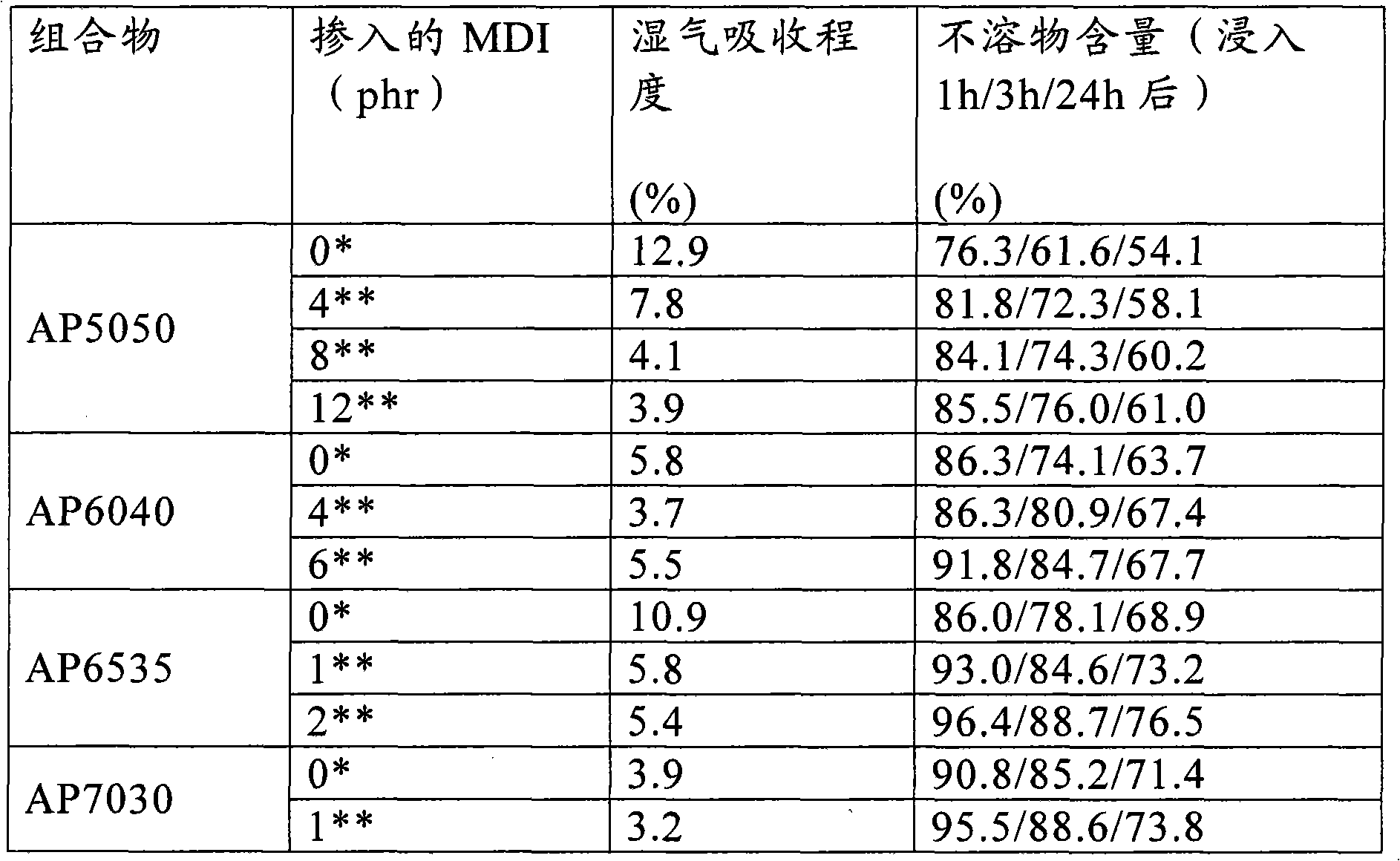

[0137] Compositions based on wheat starch according to the invention compared with compositions prepared without coupling agents according to the prior art

[0138] The ones used for this instance are:

[0139] - a native wheat starch sold by the applicant under the name "Amidon de blé SP" [Wheat Starch SP], with a moisture content of about 12% (component 1);

[0140] - a concentrated aqueous composition of glycerol-based and sorbitol-based polyols sold by the applicant under the name POLYSORB G84 / 41 / 00, having a water content of about 16% (component 2); and

[0141] - Methylene diphenyl diisocyanate (MDI) sold under the name Suprasec 1400 by Huntsman (component 3).

[0142] (a) Preparation of base thermoplastic (TPS) composition:

[0143] First, a thermoplastic composition according to the prior art is prepared. To this end, the starch and plasticizer were fed to a TSA brand twin-screw extruder with a diameter (D) of 26 mm and a length of 56 D to give a total material thro...

Embodiment 2

[0181] Addition of a functional substance

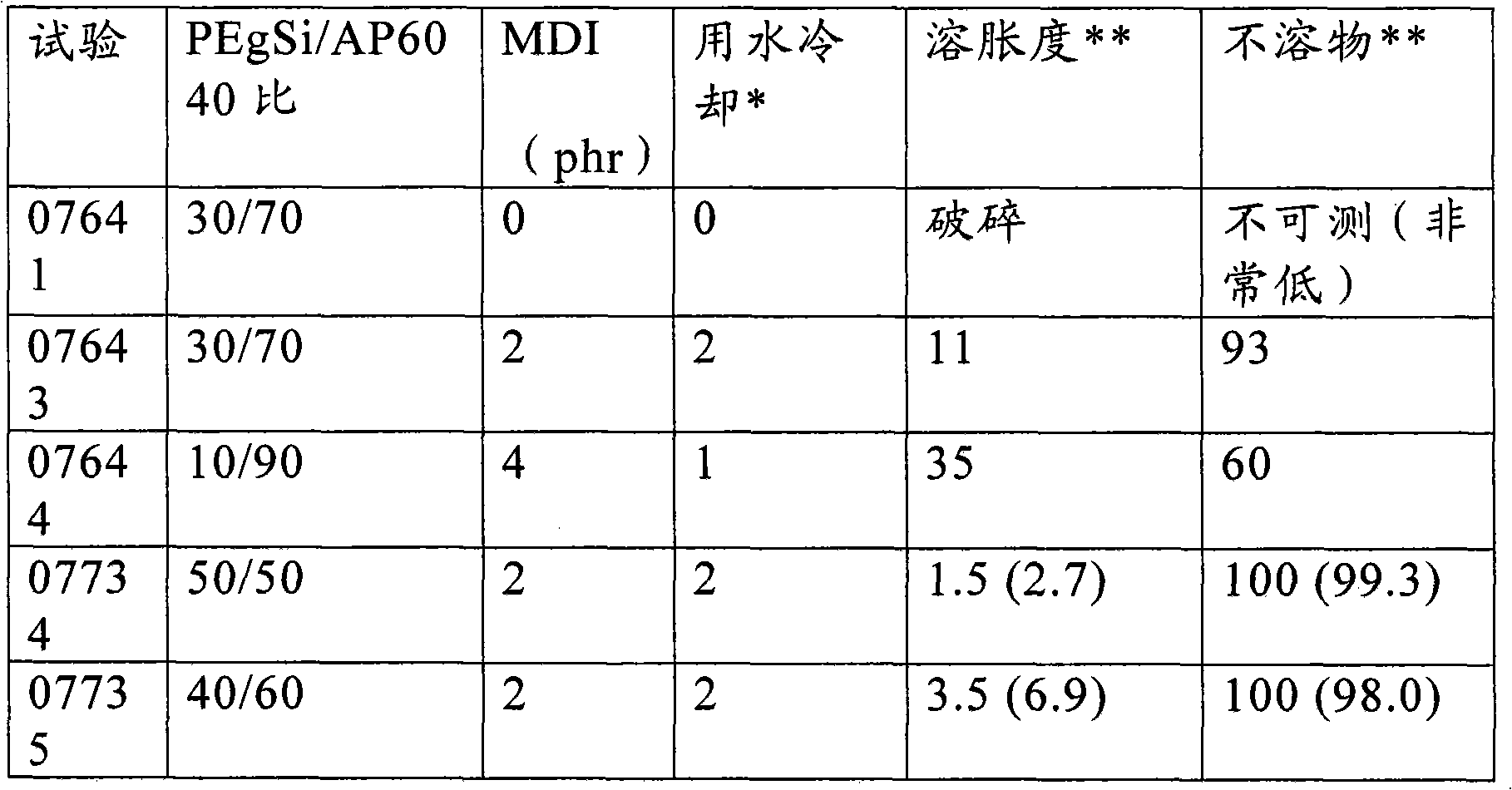

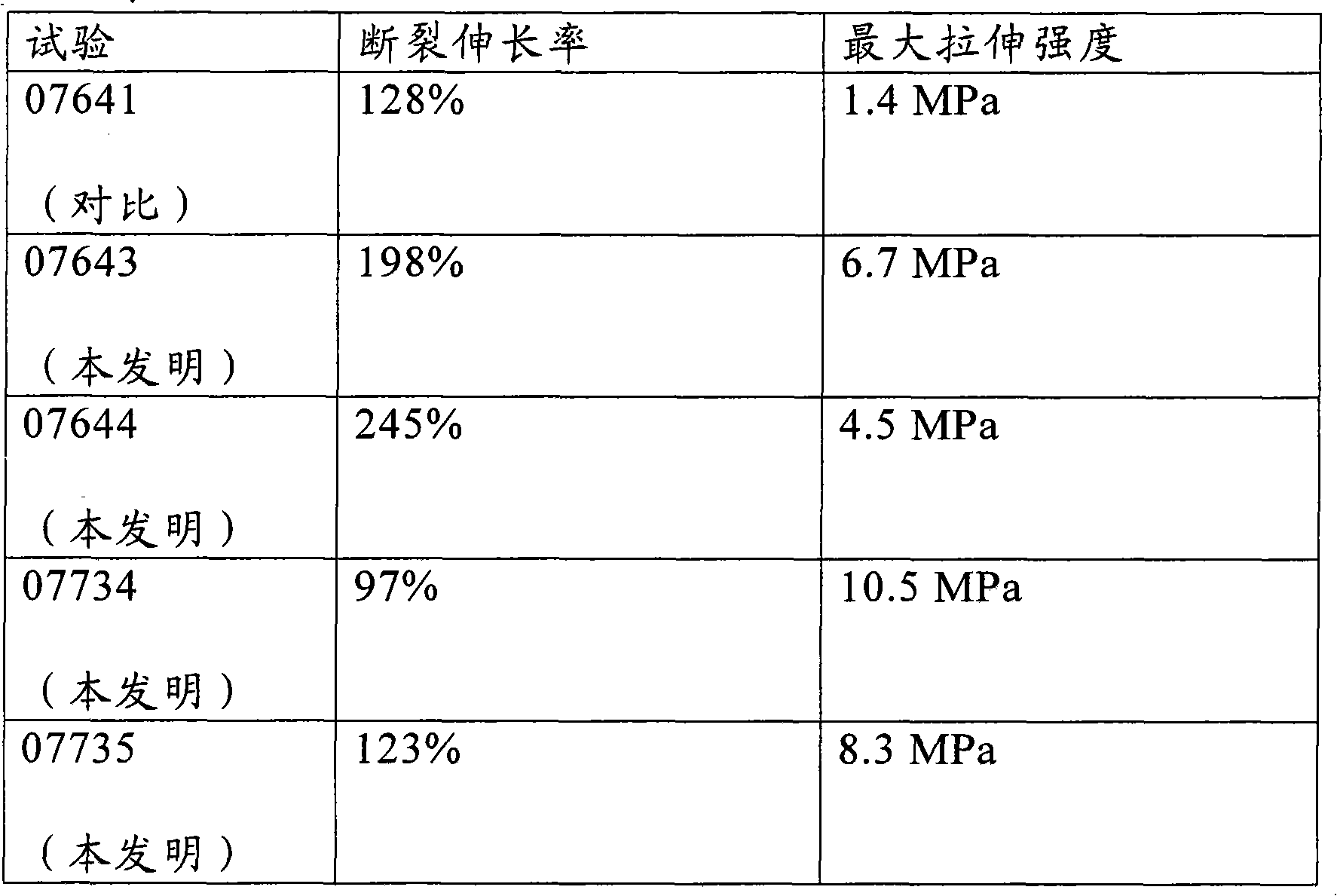

[0182]For the purpose of further increasing the water stability of the base thermoplastic starch mixture AP6040 obtained according to Example 1, MDI and a polyethylene grafted with 2% vinyltrimethoxysilane (PEgSi) were carried out with this composition. Mix to form a dry blend. The PegSi used was previously obtained by grafting vinyltrimethoxysilane onto a low-density PE by extrusion. As an example of such a commercially available PEgSi, mention may be made of the products BorPEX ME2510 or BorPEX HE2515, both sold by Boréalis.

[0183] This dry blend was fed into the previously described twin screw extruder.

[0184] The extrusion conditions are as follows:

[0185] - temperature profile (10 heating zones Z1 to Z10): 150 °C;

[0186] - Screw speed: 400 rpm.

[0187] The following compositions were prepared by introducing different amounts of MDI: 2 and 4 parts per hundred parts of thermoplastic composition AP60400 (phr).

[018...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com