Preparation method of aplitic tungsten-titanium alloy

A tungsten-titanium alloy and fine-grained technology, which is applied in the field of fine-grained tungsten-titanium alloy preparation, can solve the problems of restricting the commercialization of WTi alloy grain refinement alloys, high requirements for equipment and operators, and grain growth. Good barrier effect, reduced dynamic conditions, high density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

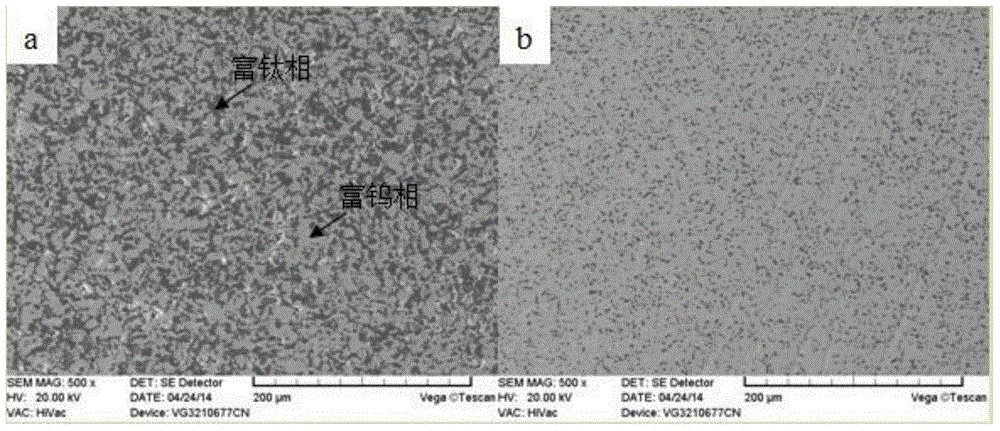

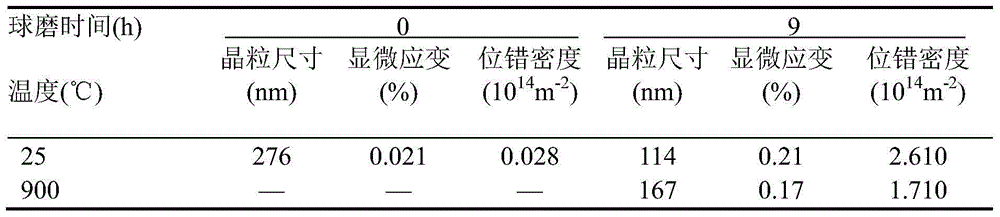

[0019] The preparation method of the fine-grained tungsten-titanium alloy of the present invention comprises high-energy ball milling of tungsten powder, adding titanium hydride powder and mixing uniformly, pressing into a green body, and hot extrusion quenching after vacuum low-temperature sintering to obtain the fine-grained tungsten-titanium alloy.

[0020] Specifically follow the steps below:

[0021] Step 1, put tungsten powder with a particle size of 6-8μm into the ball mill tank, and add 5% alcohol as a dispersant, add WC balls according to the ball-to-material ratio of 10-20:1, and then pre-pump the ball mill tank Rinse into argon after vacuuming, put the sealed ball mill jar into a planetary high-energy ball mill for ball milling, the speed is 400r / min, and the ball milling time is 6-15h;

[0022] Step 2, mix the ball-milled tungsten powder and titanium hydride powder on a V-type mixer, and then press the mixed powder into a green body at a pressure of 40t on a TM-106...

Embodiment 1

[0030] Step 1, put tungsten powder with a particle size of 6-8 μm into the ball mill tank, add 5% alcohol as a dispersant, add WC balls according to the ball-to-material ratio of 20:1, and then pre-vacuumize the ball mill tank Rush into argon, put the sealed ball mill jar into a planetary high-energy ball mill for ball milling, the speed is 400r / min, and the ball milling time is 10h;

[0031] Step 2, mix the ball-milled tungsten powder and titanium hydride powder on a V-type mixer, and then press the mixed powder into a green body at a pressure of 40t on a TM-106 hydraulic press;

[0032] Step 3, put the green body pressed in step 2 into a vacuum sintering furnace, and evacuate to 10 -3 Heating after Pa, raising the temperature to 500°C at a heating rate of 10°C / s for 2 hours, and cooling with the furnace to obtain a sintered body of WTi alloy;

[0033] Step 4, put the sintered body of WTi alloy obtained in step 3 into a stainless steel sheath, then vacuumize and weld the she...

Embodiment 2

[0036] Step 1, put tungsten powder with a particle size of 6-8 μm into the ball mill tank, add 5% alcohol as a dispersant, add WC balls according to the ball-to-material ratio of 15:1, and then pre-evacuate the ball mill tank Rush into argon, put the sealed ball mill jar into a planetary high-energy ball mill for ball milling, the speed is 400r / min, and the ball milling time is 15h;

[0037] Step 2, mix the ball-milled tungsten powder and titanium hydride powder on a V-type mixer, and then press the mixed powder into a green body at a pressure of 40t on a TM-106 hydraulic press;

[0038] Step 3, put the green body pressed in step 2 into a vacuum sintering furnace, and evacuate to 10 -3 Heating after Pa, raising the temperature to 550°C at a heating rate of 10°C / s for 1.5h, and cooling with the furnace to obtain a sintered body of WTi alloy;

[0039]Step 4, put the sintered body of WTi alloy obtained in step 3 into a stainless steel sheath, then vacuumize and weld the sheath, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com