Packaging bag printing device

A printing device and packaging bag technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of not meeting people's needs and reducing the printing effect of packaging bags, achieve good blocking effect, ensure stability, and improve printing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

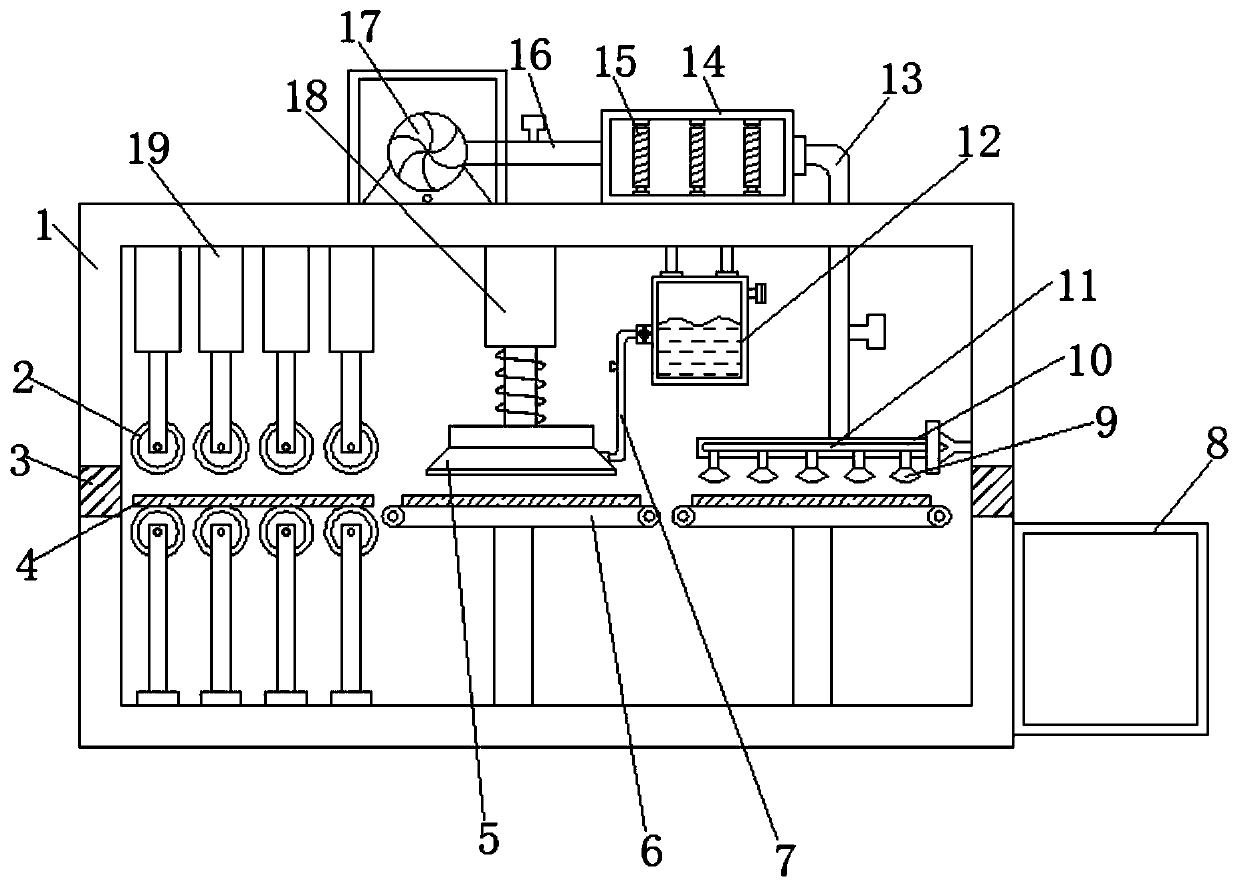

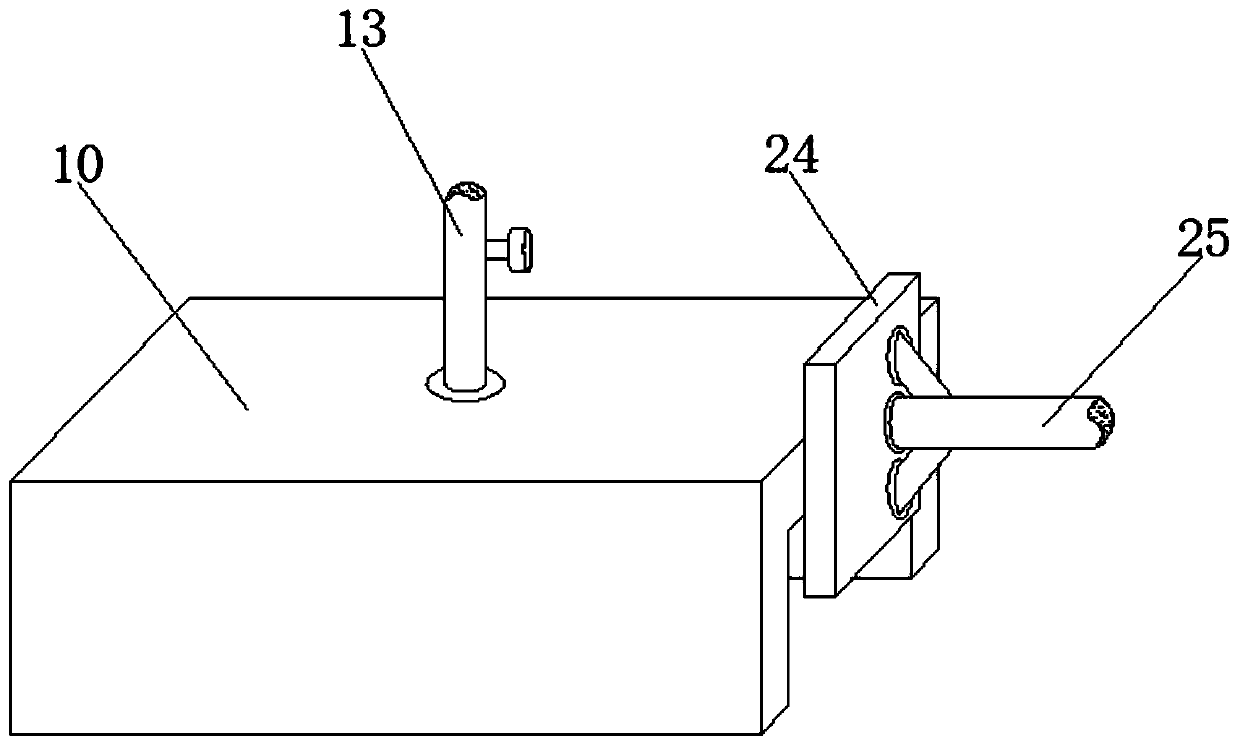

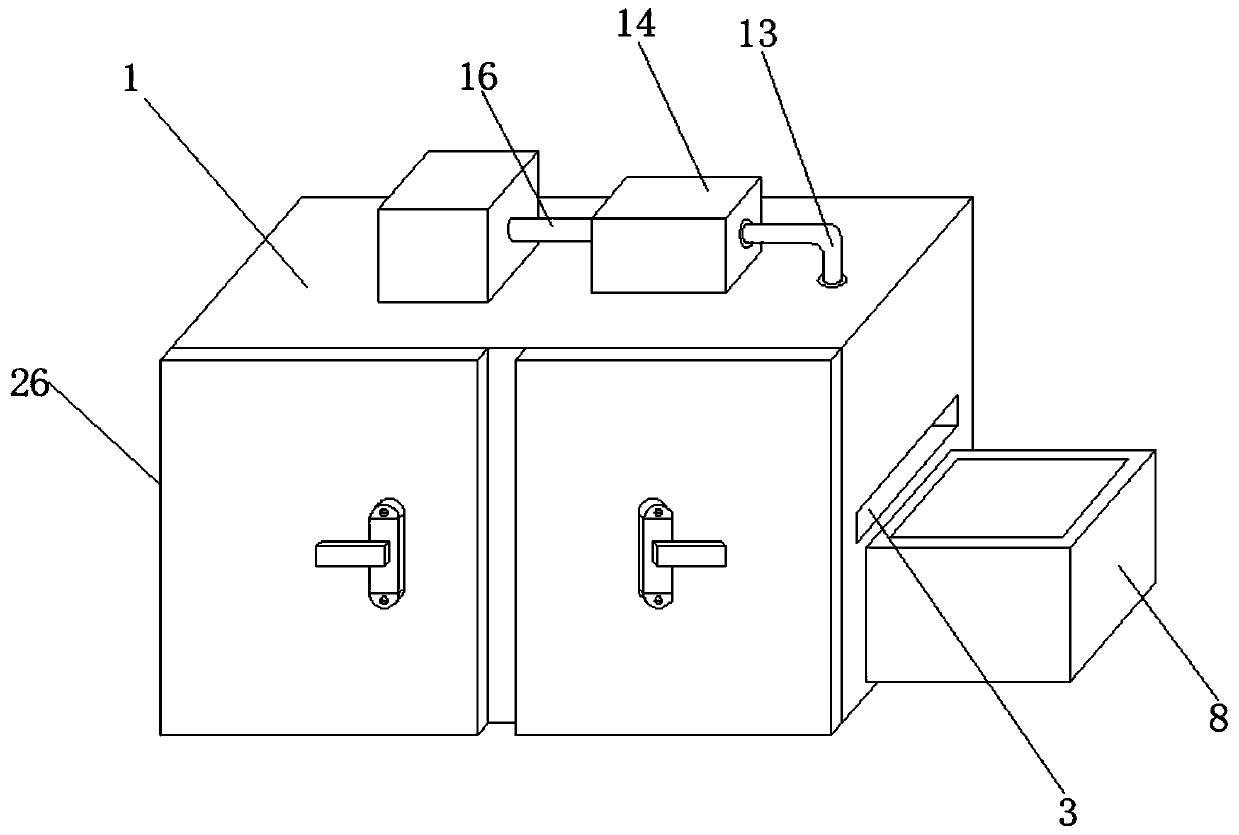

[0030] refer to Figure 1-3 , a packaging bag printing device, including a box body 1, the bottom inner wall of the box body 1 is connected with a second electric push rod 19 through bolts, and the outer wall of one side of the second electric push rod 19 is rotatably connected with a transmission roller 2, and the box body The bottom inner wall of 1 is connected with a support rod through bolts, and the outer wall of one side of the support rod is rotatably connected with a driven roller, the top outer wall of the driven roller is placed with the packaging bag body 4, and the outer walls of both sides of the box body 1 are opened. Groove 3, the top inner wall of the box body 1 is connected with the first electric push rod 18 by bolts, and the outer wall of one end of the first electric push rod 18 is connected with the printing head 5 by bolts, and the outer wall of one end of the first electric push rod 18 is sleeved with The spring, the top inner wall of the box body 1 is c...

Embodiment 2

[0034] refer to Figure 4 , a packaging bag printing device. Compared with Embodiment 1, the top outer wall of the box body 1 is connected with an air pump 20 by bolts, and an air suction pipe 21 is plugged into one side of the air pump 20. The air suction pipe 21 One end of the dust box 22 is plugged in, and the inner walls on both sides of the dust box 22 are connected with dust filter bags 23 by bolts.

[0035] Working principle: When in use, the air pump 20 can be activated before the device prints the packaging bag, which can effectively suck the dust on the surface of the packaging bag body 4 into the dust collection box 22, thereby improving the pressure of the subsequent printing head 5 on the packaging bag body 4. Printing effect, then when the staff inserts the packaging bag body 4 from the through slot 3, the second electric push rod 19 can be activated, and the second electric push rod 19 drives the transmission roller 2 to move down to clamp and fix the packaging ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com