Thermoplastic or elastomeric compositions based on esters of a starchy material and method for preparing such compositions

A technology of starch materials and compositions, applied in food science, chewing gum, applications, etc., can solve the problems of poor water resistance of water-soluble compositions, physical and chemical stability limiting potential uses, and insufficient satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0207] Example 1: Preparation of compositions according to the invention

[0208] Preparation of the composition

[0209] The ones used for this instance are:

[0210] - an acetate of potato starch as an ester of starch material, which acetate has an ester DS of 2.7 and is hereinafter denoted by "ACET 1";

[0211] - a liquid composition of glycerol triacetate (glycerol triacetate) as a plasticizer for the esters of the starch material;

[0212]- a thermoplastic polymer, in this case PLA (polylactic acid) as a polymer other than starch;

[0213] - A by Noveon in ESTANE Elastomeric polymers of the polyether TPU type sold under 58887 as polymers other than starch;

[0214] - a low-density polyethylene (LDPE) as a polymer other than starch,;

[0215] - A by Polyram in BONDYRAM Maleic anhydride-grafted polyethylene sold under 4001 as polymers other than starch;

[0216] - Methylene diphenyl diisocyanate (MDI) sold under the name Suprasec 1400 by Huntsman as coupling ag...

example 2

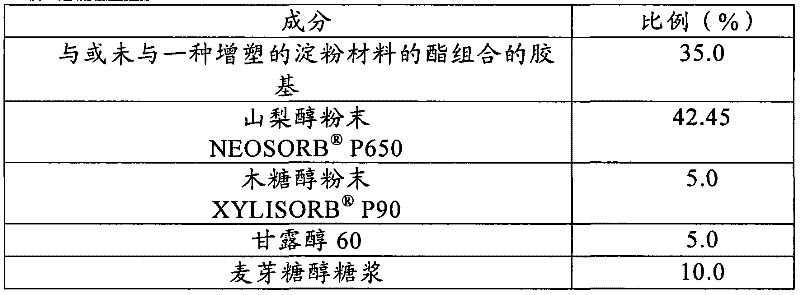

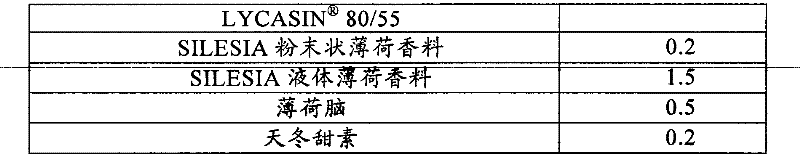

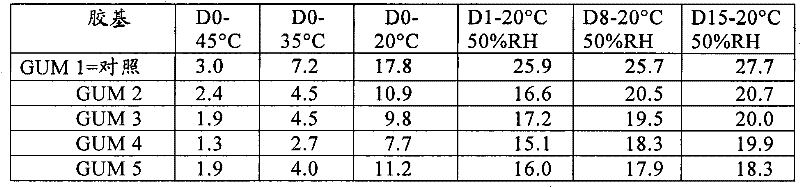

[0242] Example 2: Use of the elastomer composition according to the invention in the preparation of chewing gum

[0243] In the context of this example, the possibility of using a composition according to the invention to at least partially replace a gum base based on a synthetic polymer for the production of chewing gum was evaluated.

[0244] 2.1: Raw materials

[0245] The main raw materials used in this example are:

[0246] - Esters as starch materials, respectively:

[0247] ○ A kind of maltodextrin derived from waxy corn starch (maltodextrin GLUCIDEX sold by the applicant 2) acetates having an ester DS of around 2.7 (hereinafter denoted by "ACET 2");

[0248] o An acetate of fluidized corn starch, in this case the starch CLEARGUM sold by the applicant MB80, the acetate has an ester DS of around 2.5 (hereinafter denoted by "ACET 3");

[0249] o An acetate (DS of 0.45) of potato starch, subsequently grafted with ε-caprolactone, the resulting starch material ha...

example 3

[0295] Example 3: Preparation of an ester based on a plasticized starch material and a TPU type ester polymer A composition according to the invention :

[0296] Preparation of the composition

[0297] The ones used for this instance are:

[0298] - acetate of maltodextrin ACET 2 as described in example 2 as ester of plasticized starch material;

[0299] - benzyl alcohol as plasticizer in an amount of 15 parts by weight per 100 parts by weight of said ester;

[0300] - A by Noveon in ESTANE Polymers of the ester TPU type sold under 58447 as polymers other than starch;

[0301] - Methylene diphenyl diisocyanate (MDI) sold under the name Suprasec 1400 by Huntsman as coupling agent.

[0302] The composition according to the invention produced under the general conditions of Example 1 (hereinafter "COMP 5") comprises:

[0303] -50 servings of ESTANE 58447 polymer;

[0304] - 50 parts by weight of plasticized ACET 2 ester; and

[0305] - 1 part by weight of MDI. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Maximum tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com