Elastomeric compositions based on esters of a starchy material and method for preparing such compositions

A technology for starch materials and compositions, applied in the fields of food science, chewing gum, applications, etc., can solve the problems of physical and chemical stability limiting potential use, insufficient satisfaction, poor water resistance of water-soluble compositions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0208] Example 1: Preparation of an elastomer composition according to the present invention

[0209] Preparation of the composition

[0210] The ones used in this example are:

[0211] -An acetate of potato starch as the ester of the starch material, the acetate has an ester DS of 2.7 and is denoted by "ACET 1" hereinafter;

[0212] -A liquid composition of glycerol triacetate (glyceryl triacetate) as a plasticizer for the ester of this starch material;

[0213] -One by Noveon in ESTANE The polyester TPU type polymer sold under the name 58887 is a non-starch polymer of elastomer;

[0214] -Methylene biphenyl diisocyanate (MDI) sold under the name Suprasec 1400 by Huntsman as a coupling agent.

[0215] First, a controlled composition was produced through several steps, the composition containing by weight:

[0216] -30% of ACET 1 ester of starch material;

[0217] -20% triacetin; and

[0218] -50% PLA (polylactic acid).

[0219] In the first step, 60 parts of ACET 1 ester and 40% parts of ...

example 2

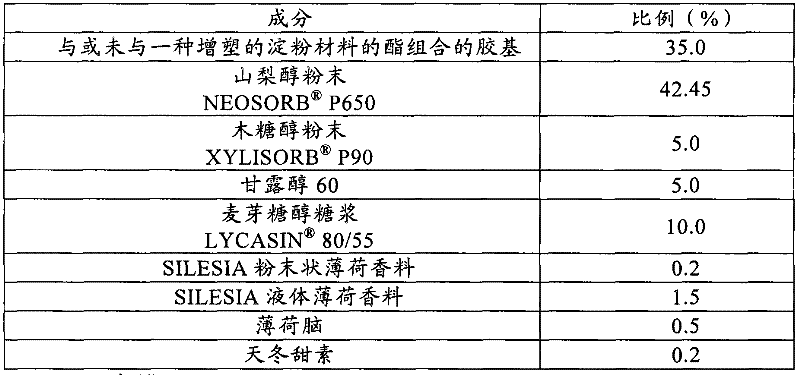

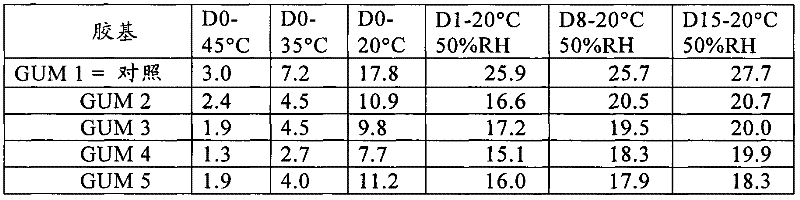

[0239] Example 2: Use of the elastomer composition according to the present invention in the preparation of chewing gum

[0240] In the context of this example, the possibility of using the composition according to the invention to replace at least partly a gum base based on a synthetic polymer for the preparation of chewing gum was evaluated.

[0241] 2.1: Raw materials

[0242] The main raw materials used in this example are:

[0243] -Esters used as starch materials are:

[0244] ○ A kind of maltodextrin derived from waxy corn starch (the maltodextrin sold by the applicant GLUCIDEX 2) Acetate ester, which has an ester DS of about 2.7 (hereinafter referred to as "ACET 2");

[0245] ○ An acetate of fluidized corn starch, in this case the starch CLEARGUM sold by the applicant MB80, the acetate has an ester DS of about 2.5 (hereinafter referred to as "ACET 3");

[0246] ○An acetate of potato starch (DS of 0.45), and then grafted with ε-caprolactone, the resulting starch material este...

example 3

[0291] Example 3: Elastomer based on an ester of a plasticized starch material and a TPU type ester Preparation of a composition according to the present invention

[0292] Preparation of the composition

[0293] The ones used in this example are:

[0294] -The acetate of maltodextrin ACET 2 as described in Example 2 as the ester of plasticized starch material;

[0295] -15 parts by weight of benzyl alcohol per 100 parts by weight of the ester as a plasticizer;

[0296] -One by Noveon in ESTANE The ester TPU type polymer sold under the name 58447 is a non-starch polymer of elastomers;

[0297] -Methylene biphenyl diisocyanate (MDI) sold under the name Suprasec 1400 by Huntsman as a coupling agent.

[0298] The composition according to the present invention produced under the general conditions of Example 1 (hereinafter "COMP 5") contains:

[0299] -50 servings of ESTANE 58447 polymer;

[0300] -50 parts by weight of plasticized ACET 2 ester; and

[0301] -1 part of MDI by weight.

[03...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com