Condom and preparation method thereof

A condom and film technology, which is applied to male contraceptives and other directions, can solve the problems of complex preparation process, low elasticity, poor barrier properties, etc., and achieve the effects of simple process, improved barrier properties, and high barrier efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

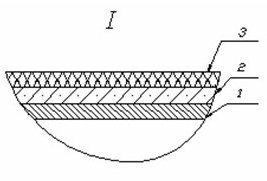

[0029] The present invention also provides a preparation method of the condom, comprising the following steps:

[0030] 1) Dip the rod-shaped mold in the inner latex, take it out and dry it to form the first layer of film on the surface of the rod-shaped mold;

[0031] 2) Dip the rod-shaped mold with the first layer of film on the surface into the middle layer of latex, take it out and dry it to form a second layer of film on the surface of the first layer of film;

[0032] 3) Dip the rod-shaped mold with the first film and the second film on the surface obtained in step 2) into the outer latex, take it out and dry it, and continue to form the third film on the surface of the second film;

[0033] 4) Demoulding and vulcanizing the product of step 3) to obtain the condom;

[0034] Wherein, the intermediate film is a water-based polyurethane film or a polyisoprene film.

[0035] In the present invention, the preparation method of the condom is not particularly limited, and the...

Embodiment 1

[0040] 1) Immerse the male condom rod mold in the inner latex, take it out and dry it, and form the first layer of film on the surface of the rod mold; the inner latex is water-based polyurethane latex.

[0041] 2) Dip the rod-shaped mold with the first layer of film on the surface into the middle layer latex, take it out and dry it to form a second layer of film on the surface of the first layer of film; the middle layer latex is water-based polyurethane latex.

[0042] 3) Dip the rod-shaped mold with the first film and the second film on the surface obtained in step 2) into the outer latex, take it out and dry it, and continue to form the third film on the surface of the second film; the outer latex It is water-based polyurethane latex.

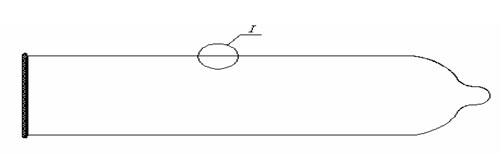

[0043] 4) Demoulding and vulcanizing the product of step 3) to obtain the male condom S1 of this embodiment, as shown in figure 1 shown.

Embodiment 2

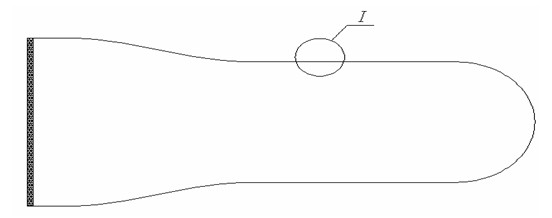

[0045] Adopt the method identical with embodiment 1 to prepare the condom S2 of the present embodiment, difference is:

[0046] In step 1), the female condom rod mold is used to replace the male condom rod mold in Example 1; the inner latex is water-based polyurethane latex with an antibacterial agent added;

[0047] In step 2), the middle layer latex is water-based polyurethane latex;

[0048] In step 3), the outer latex is water-based polyurethane latex with antibacterial agent added.

[0049] Through the above steps, obtain the female condom S2 of the present embodiment, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com