Perfumed aluminum-free composite inner liner paper for multi-coating cigarettes as well as preparation method and device of perfumed aluminum-free composite inner liner paper

A composite device, multi-coating technology, applied in lamination devices, coatings, chemical instruments and methods, etc., can solve the problems of poor barrier and mildew resistance, single function, etc., to expand the scope of use, high safety good barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

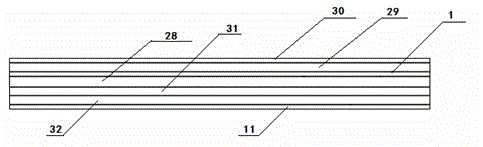

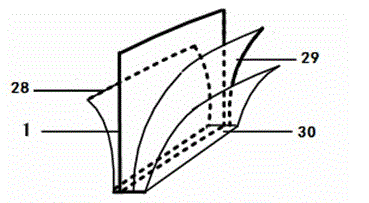

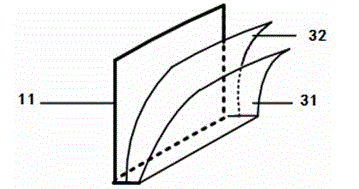

[0029] Prepare multi-coated flavoring aluminum-free composite inner liner paper for cigarettes as follows: figure 1 , 2, 3, base paper is carried out double-sided and single-sided coating respectively, double-sided coated base paper 1 is to be coated with barrier layer 28 and functional coating 29 respectively on both sides, single-sided coated base paper 11 is to be coated on one side successively There is a functional coating 32 and a flavoring coating 31, and the base paper 11 coated on one side is compounded with the barrier layer 28 of the base paper 1 coated on both sides with the flavoring coating 31, and then on the functional coating 29 as required. Dyeing and drying with hot air, and finally knurling to form the surface layer 30 .

[0030] Above-mentioned preparation method realizes by following coating composite device: as Figure 4 , including a double-sided coating part, a single-sided coating part and a composite part, wherein the double-sided coating part is s...

Embodiment 2

[0034] The preparation method and coating composite device are the same as in Example 1, only the flavoring coating solution is replaced by the following components by mass percentage: 0.7-0.95% Zimbabwe extract, 1.1-1.3% plum extract, 0.88-0.97% jujube Extract, 2.0-2.3% black tea, 0.88-0.97% apple, 1.7-1.9% grape, 0.25-0.32% rose oil (mass concentration of rose oil is 10%), 1% red big fireworks extract, propylene glycol (substrate) for the margin. The application amount of the perfuming coating solution is 0.4-0.5% of the mass percentage of the base paper. The coating solution highlights the original aroma of tobacco, and improves the coordination with the smell and aroma of cigarettes.

Embodiment 3

[0036] The preparation method and coating composite device are the same as in Example 1, except that the flavored coating liquid is replaced by mixing the two flavored coating liquids of Examples 1 and 2 in equal volumes. The application amount of the flavoring coating liquid is 0.4-0.5% of the mass percentage of the base paper. The coating solution highlights the original aroma of tobacco, and improves the coordination with the smell and aroma of cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com