Intelligent and comprehensive dry-mixed mortar wall coating system

A dry-mixed mortar and integrated system technology, applied in construction, building construction, etc., can solve the problems of uncontrollable opening and closing of mortar conveying pumps, cumbersome equipment installation and transportation, and labor-intensive workers, so as to reduce dust spread and construction. High efficiency and the effect of reducing mortar waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

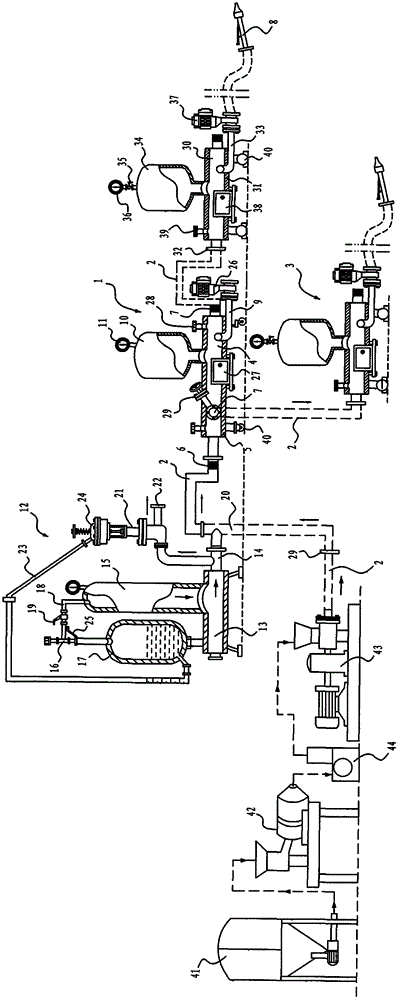

[0022] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

[0023] Such as figure 1 As shown, it includes a mortar storage tank 41, a continuous cement mortar mixer 42, a secondary mixing storage tank 44, and a mortar delivery pump 43 connected in sequence through the delivery pipeline 2, and also includes a direct connection with the delivery pipeline 2 through the delivery pipeline 2. The mortar spraying automatic distribution system connected with the mortar delivery pump 43, the mortar spraying automatic distribution system includes a main spraying distribution machine 1 and a plurality of auxiliary spraying distributions connected with the main spraying distribution machine 1 through the material delivery pipeline 2 machine 3;

[0024]The main spraying distributor 1 includes a base 5 with a feed chamber 4, the base 5 is provided with a feed port 6 communicating with the feed chamber 4 for connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com