Spray cleaning machine used for garden greening

A landscaping and washing machine technology, applied in gardening, application, spraying device and other directions, can solve the problems of limited work efficiency and high physical strength requirements of workers, and achieve the effect of facilitating spraying work, reducing labor intensity and avoiding shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

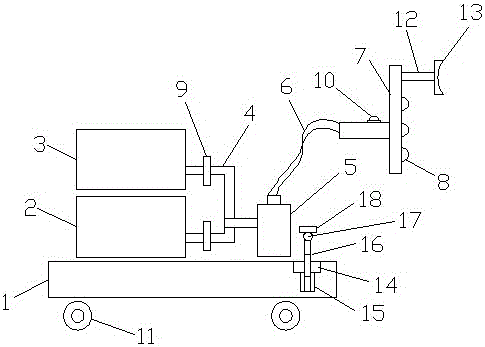

[0011] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0012] A spray cleaning machine for landscaping, comprising a base 1, on which a water storage tank 2 and a mortar tank 3 are arranged, and the water storage tank 2 and the mortar tank 3 are both connected to the input end of a jet pump 5 through a conduit 4 , the output end of the jet pump 5 is connected to the T-shaped handle 7 through the hose 6, the T-shaped handle 7 is a hollow structure, and the side wall of the T-shaped handle 7 is provided with three spray heads 8, the The conduit 4 is provided with a flow control valve 9, the upper end of the T-shaped handle 7 is provided with a support arm 12, and the end of the support arm 12 is provided with an arc-shaped card body 13, and the arc-shaped card body 13 is provided with A rubber backing plate, the end of the base 1 is provided with a groove 14, and the bottom end of the groove 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com