Before-welding assembly automation device for edge grinding wheel

A technology of automation equipment and edging wheel, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve high assembly efficiency, excellent assembly effect, and reduce sliding frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

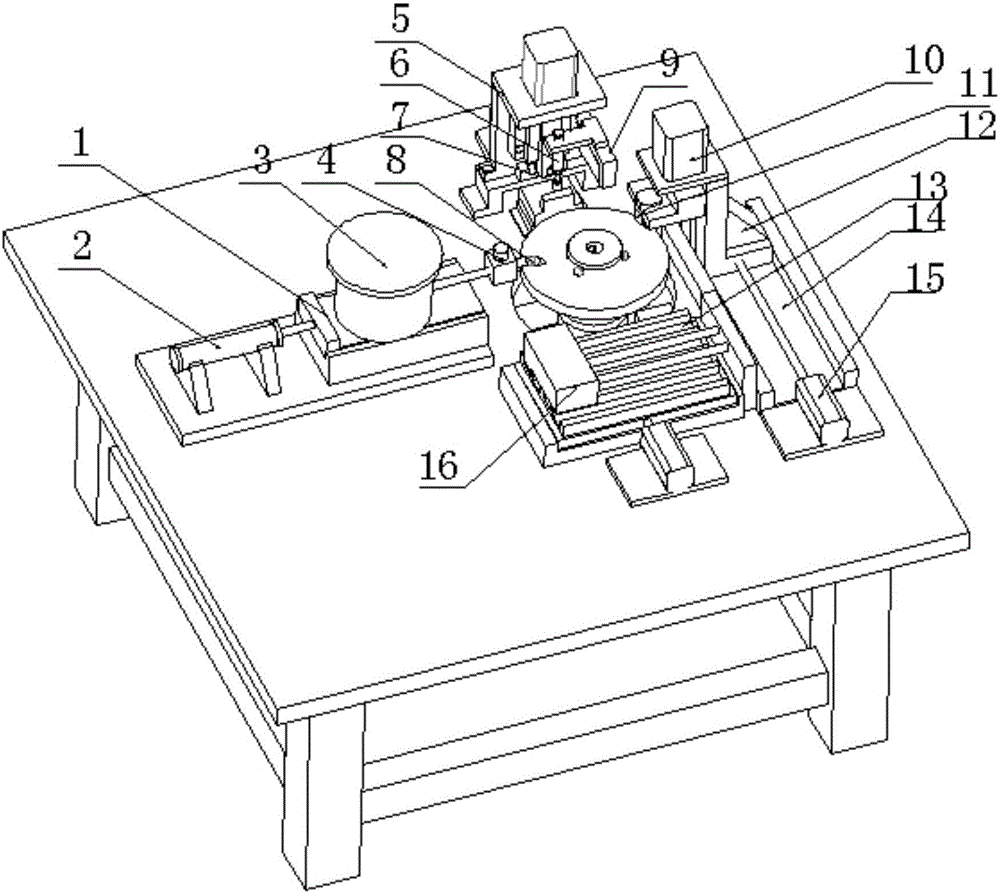

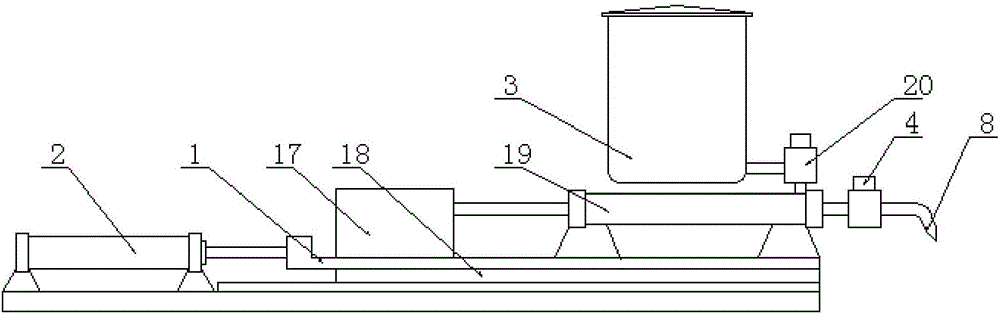

[0026] see figure 1 , a kind of edging wheel assembly automation equipment before welding, including a frame main body, an assembly station hole is provided on the operating platform of the frame main body, a rotating device is provided below the assembly station hole, and a rotating device is installed on the rotating device The substrate can be fixed and driven to rotate. The outer side of the assembly station hole is equipped with a cutter head feeding system, a welding rod feeding system and a flux spraying feeding system. The flux spraying feeding system, welding rod feeding system and cutter head feeding system The feeding devices of the three can deliver the material to the edge of the substrate by moving toward the substrate.

[0027] In the present invention, a rotating device is provided below the hole of the assembly station. The substrate is fixed on the rotating device and can drive the substrate to rotate. The flux spraying system sprays flux to the edge of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com