Steel component spraying device easy to fix on site

A technology of spraying device and steel components, applied in the direction of spraying device, etc., can solve the problems of inconvenience to use on construction site, inconvenient spraying of steel components, troublesome fixed installation method, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

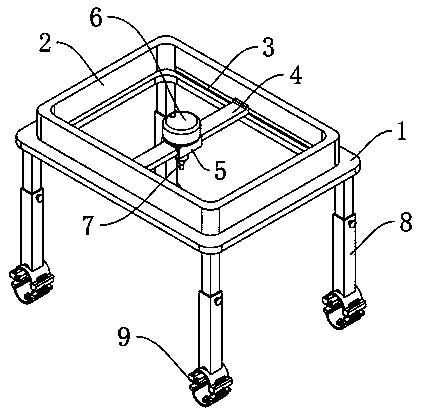

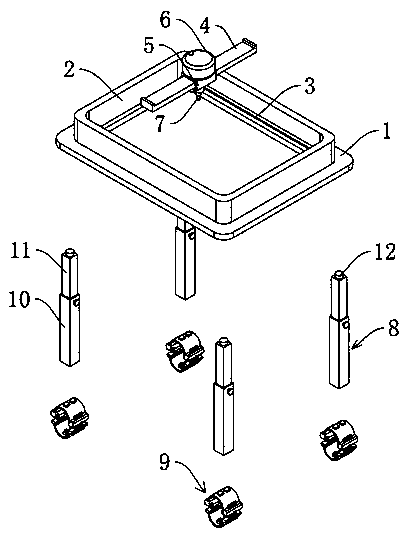

[0029] See Figure 1-2 , A spraying device for steel components that is easy to fix on site, including a connecting plate 1 and a mounting plate 2. The mounting plate 2 is fixedly connected to the connecting plate 1, and the inner wall of the mounting plate 2 is provided with a chute 3, which slides on the chute 3. A mounting frame 4 is connected, a connecting sleeve 5 is slidably installed on the mounting frame 4, a paint storage tank 6 is fixedly connected to the upper surface of the connecting sleeve 5, and a spraying mechanism 7 is fixedly installed on the lower surface of the connecting sleeve 5. The paint storage tank 6 is matched; the lower surface of the connecting plate 1 is connected with a supporting mechanism 8. The supporting mechanism 8 includes a supporting rod 10 and a telescopic rod 11. The telescopic rod 11 is telescopically connected to the supporting rod 10, and the top of the telescopic rod 11 is fixedly installed The bearing 12 is connected, the supporting ...

Embodiment 2

[0032] See Figure 3-6 , Based on Example 1, the difference is:

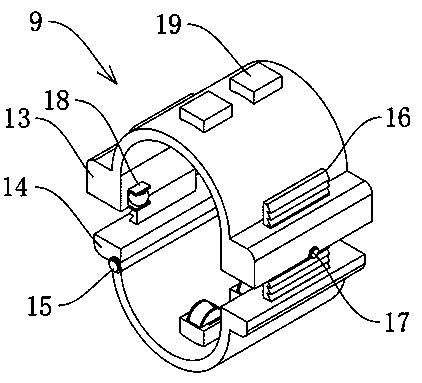

[0033] The fixed connection mechanism 9 includes an upper fixing portion 13 and a lower fixing portion 14. The upper fixing portion 13 includes an upper connecting block and an upper fixing arc tube, and the lower fixing portion 14 includes a lower connecting block and a lower fixing arc tube. A hinge 15 is fixedly installed on the edge of the lower end, and the lower fixed arc tube is movably connected with the lower connecting block through the hinge 15.

[0034] The lower connecting block is fixedly connected to the limiting tooth plate 16, the upper connecting block is provided with a through groove 20, the through groove 20 matches the limiting tooth plate 16, and the inside of the upper connecting block is also installed with a limiting adjusting mechanism 17 near the through groove 20 , The limit adjustment mechanism 17 is matched with the limit tooth plate 16; the upper connecting block is also provided with ...

Embodiment 3

[0038] Reference Figure 7-8 ; Based on embodiment 1 or 2, the difference is that;

[0039] The lateral movement mechanism 18 includes a first connecting frame 27. The inside of the first connecting frame 27 is provided with a spherical roller 28. The spherical roller 28 is fixedly connected with a protruding shaft 29. The spherical roller 28 is rotatably connected to the first connecting frame through the protruding shaft 29. On the frame 27, a second spring 30 is fixedly connected to the outer wall surface of the first connecting frame 27, and one end of the second spring 30 away from the first connecting frame 27 is fixedly connected to the inner wall of the mounting groove 21.

[0040] The longitudinal movement promoting mechanism 19 includes a connecting cover 31, which is fixedly connected to the upper fixed arc tube or the lower fixed arc tube. A second connecting frame 32 is provided inside the connecting cover 31, and a groove is rotatably connected to the second connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com