Stainless steel composite steel pipe and manufacturing method thereof

A composite steel pipe and stainless steel pipe technology, applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of base pipe plasticity, toughness damage, high raw material costs, and increased manufacturing costs, and achieve simple processes, Good corrosion resistance, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

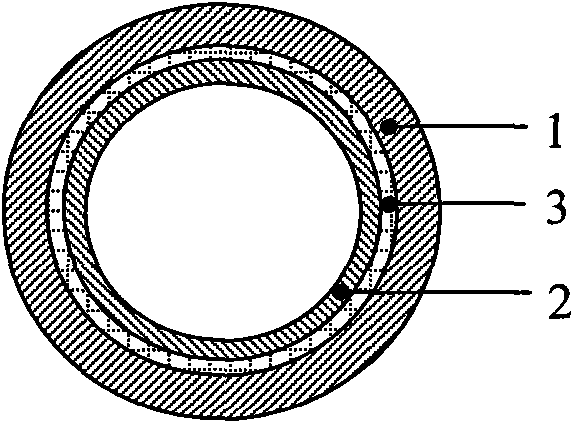

[0019] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: the product of the embodiment of the present invention is the same as the prior art, including the outer carbon steel pipe, the inner stainless steel pipe and the diffusion brazing layer between the carbon steel pipe and the stainless steel pipe. What is different from the prior art is that The brass diffusion brazing layer 3 is fully filled between the outer carbon steel pipe 1 and the inner stainless steel pipe 2, and the thickness of the brass diffusion brazing layer 3 is preferably 0.02-0.1 mm.

[0020] The specific manufacturing method is:

[0021] a. Select a thin-walled austenitic stainless steel welded pipe with an outer diameter of 25mm and a wall thickness of 0.6mm as the inner pipe, and a low-carbon steel seamless steel pipe with an outer diameter of 32mm and a wall thickness of 3mm as the outer pipe, with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com