Composite reinforced wear-resistant part of metal-ceramic prefabricated member and manufacturing method of composite reinforced wear-resistant part

A composite reinforcement and ceramic composite technology is applied in the field of preparation of metal-ceramic preform composite reinforcement wear parts, and achieves the effects of strong selectivity, cost saving and good combination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

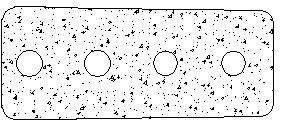

[0043] Example 1: Composite cast grinding roller liner

[0044] (1) Mix alumina ceramics with a particle size of 6-50 mesh or surface-pretreated alumina ceramics and iron-based self-fluxing alloy powder with polyvinyl alcohol to obtain a mixture, in which ceramic particles and self-fluxing alloy powder The volume ratio of the ceramic is 1:19~1:1, and the amount of polyvinyl alcohol added is 1%-6% of the ceramic mass;

[0045](2) Fill the above mixture into the cavity of the press mold, place a 2~10mm ordinary steel gasket in advance on the bottom of the cavity, place a layer of 0.2~0.5mm graphite paper on the gasket, press it with a certain pressure, and mold and demould Finally, put the biscuit together with the gasket into a drying oven at 150°C for 2 hours;

[0046] (3) Put the dried biscuit together with the gasket into a vacuum furnace at a temperature of 1000°C and a vacuum degree of 0.2-0.4Pa for sintering for 60 minutes, and after cooling out of the furnace, a metal-c...

Embodiment 2

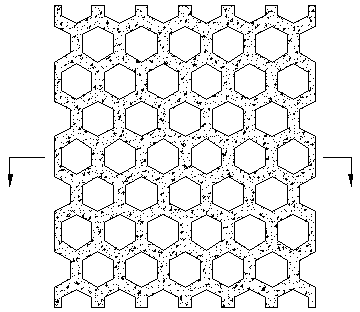

[0052] Example 2: Composite cast grinding disc liner

[0053] (1) Mix tungsten carbide ceramics with a particle size of 6~50 mesh or tungsten carbide ceramics with surface pretreatment and nickel-based self-fluxing alloy powder with polyvinyl alcohol to obtain a mixture, in which ceramic particles and self-fluxing alloy powder The volume ratio of the ceramic is 1:19~1:1, and the amount of polyvinyl alcohol added is 1%-6% of the ceramic mass;

[0054] (2) Fill the above mixture into the cavity of the press mold, place a 2~10mm ordinary steel gasket in advance on the bottom of the cavity, place a layer of 0.2~0.5mm graphite paper on the gasket, press it with a certain pressure, and mold and demould Finally, put the biscuit together with the gasket into a drying oven at 150°C for 2 hours;

[0055] (3) Put the dried biscuit together with the gasket into a vacuum furnace at a temperature of 1050°C and a vacuum degree of 0.2-0.4Pa for sintering for 90 minutes, and after cooling out...

Embodiment 3

[0061] Example 3: Composite Casting Crusher Hammer

[0062] (1) Mix titanium nitride ceramics with a particle size of 6-50 mesh or surface-pretreated titanium nitride ceramics with cobalt-based self-fluxing alloy powder with polyvinyl alcohol to obtain a mixture, in which ceramic particles and self-fluxing The volume ratio of the alloy powder is 1:19~1:1, and the amount of polyvinyl alcohol added is 1%-6% of the ceramic mass;

[0063] (2) Fill the above mixture into the cavity of the press mold, place a 2~10mm ordinary steel gasket in advance on the bottom of the cavity, place a layer of 0.2~0.5mm graphite paper on the gasket, press it with a certain pressure, and mold and demould Finally, put the biscuit together with the gasket into a drying oven at 150°C for 2 hours;

[0064] (3) Put the dried biscuit together with the gasket into a vacuum furnace at a temperature of 1300°C and a vacuum of 0.2-0.4Pa for sintering for 30 minutes, and after cooling out of the furnace, a meta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com