Centrifugal casting high-speed steel composite roll and manufacture method thereof

A composite roll and centrifugal casting technology, which is applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems that the centrifugal casting method cannot do, and achieve the effect of improving the shape and distribution of graphite, good toughness, and good impact toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

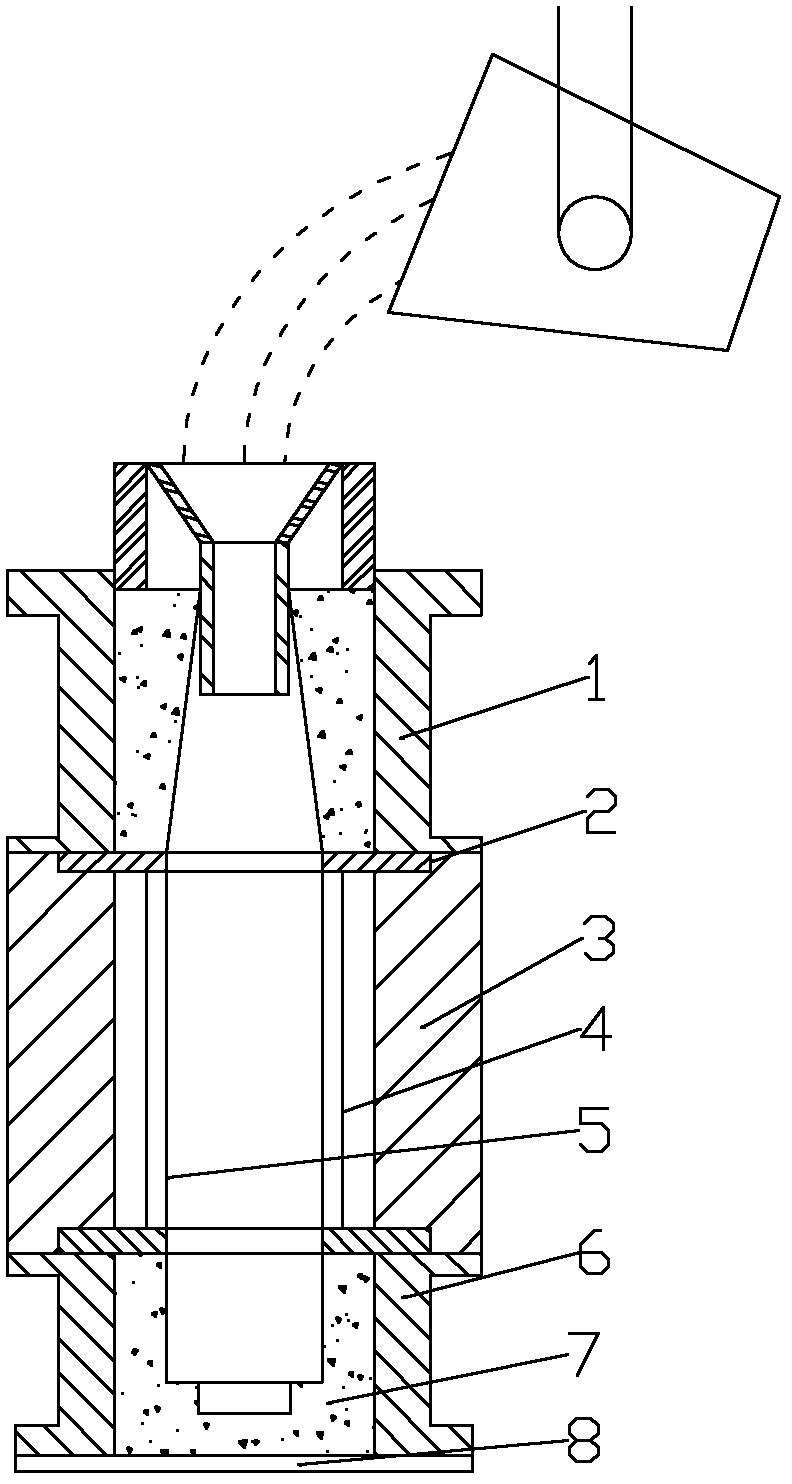

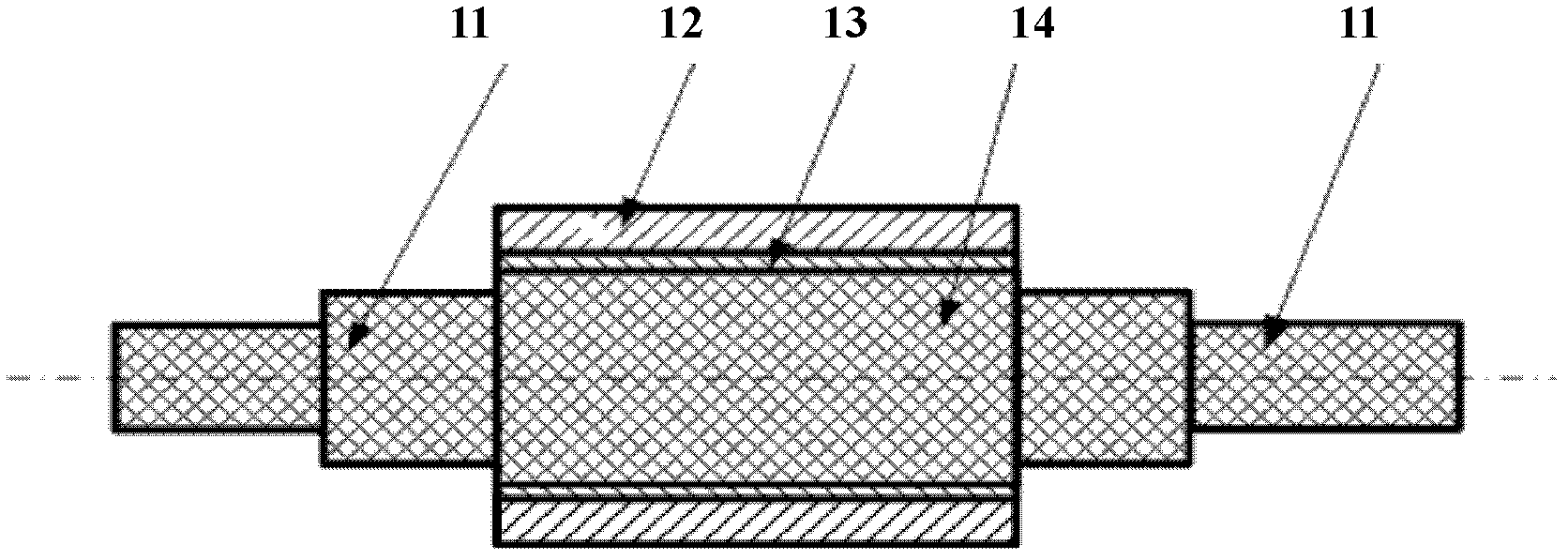

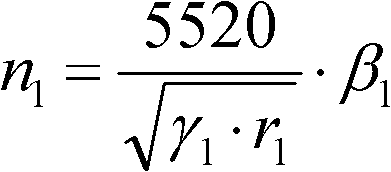

[0036] The outer high-speed steel, middle layer graphite steel and core ductile iron are smelted in 500 kg, 500 kg and 1.5 ton induction furnaces respectively, and then the outer layer and middle layer of the roll are poured on a horizontal centrifuge, and the roll core is top-cast under static conditions The manufacturing process steps of ductile iron molten iron and high-speed steel composite roll are:

[0037] (1) Smelting of outer layer high speed steel, middle layer graphite steel and core nodular iron. Among them, the smelting process of the outer high-speed steel is: ① Mix and heat scrap steel, recarburizer, ferrochrome, ferromolybdenum, ferroniobium, metal cobalt and nickel plate and heat and melt. When the temperature of molten steel rises to 1581°C, add silicon-calcium-barium alloy in turn , aluminum, ferro-vanadium and ferro-boron, and then raise the temperature to 1605°C, adjust the composition in front of the furnace and release it after passing the furnace. The ...

Embodiment 2

[0050] The outer high-speed steel, middle layer graphite steel and core ductile iron are smelted in 500 kg, 500 kg and 1.5 ton induction furnaces respectively, and then the outer layer and middle layer of the roll are poured on a horizontal centrifuge, and the roll core is top-cast under static conditions The manufacturing process steps of ductile iron molten iron and high-speed steel composite roll are:

[0051] (1) Smelting of outer layer high speed steel, middle layer graphite steel and core nodular iron. Among them, the smelting process of the outer high-speed steel is: ① Mix and heat scrap steel, recarburizer, ferrochromium, ferromolybdenum, ferroniobium, metal cobalt and nickel plate and heat and melt. When the temperature of molten steel rises to 1599°C, add silicon-calcium-barium alloy in turn , aluminum, ferro-vanadium and ferro-boron, then raise the temperature to 1628°C, and adjust the composition before the furnace to pass the furnace. The molten steel undergoes m...

Embodiment 3

[0064] The outer high-speed steel, middle layer graphite steel and core ductile iron are smelted in 500 kg, 500 kg and 1.5 ton induction furnaces respectively, and then the outer layer and middle layer of the roll are poured on a horizontal centrifuge, and the roll core is top-cast under static conditions The manufacturing process steps of ductile iron molten iron and high-speed steel composite roll are:

[0065](1) Smelting of outer layer high speed steel, middle layer graphite steel and core nodular iron. Among them, the smelting process of the outer high-speed steel is: ① Mix and heat scrap steel, recarburizer, ferrochromium, ferromolybdenum, ferroniobium, metal cobalt and nickel plate, and add silicon-calcium-barium alloy in sequence when the temperature of molten steel rises to 1592°C , aluminum, ferro-vanadium and ferro-boron, then raise the temperature to 1617°C, and adjust the ingredients before the furnace to pass the furnace. The molten steel undergoes metamorphic t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com