Method for preparing anticorrosion wear-resisting iron-based amorphous coating through laser cladding technology

An iron-based amorphous and laser cladding technology, which is applied in the field of coating materials prepared by laser processing technology, can solve the problems of poor comprehensive performance of anti-corrosion and wear resistance, uneven structure, holes and cracks, etc., and achieve excellent comprehensive performance of corrosion resistance , Uniform structure, no cracks and hole defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: The chemical composition of the Fe-based amorphous alloy powder is: Cr: 17.3-19.4%; Mn: 1.8-2.2%; Mo: 12.9-15.8%; W: 5.0-6.2%; B: 2.8-4.1% ; C: 0.7-1.1%; Si: 1.0-1.5%; the rest is Fe; (mass percentage), the total mass satisfies 100%.

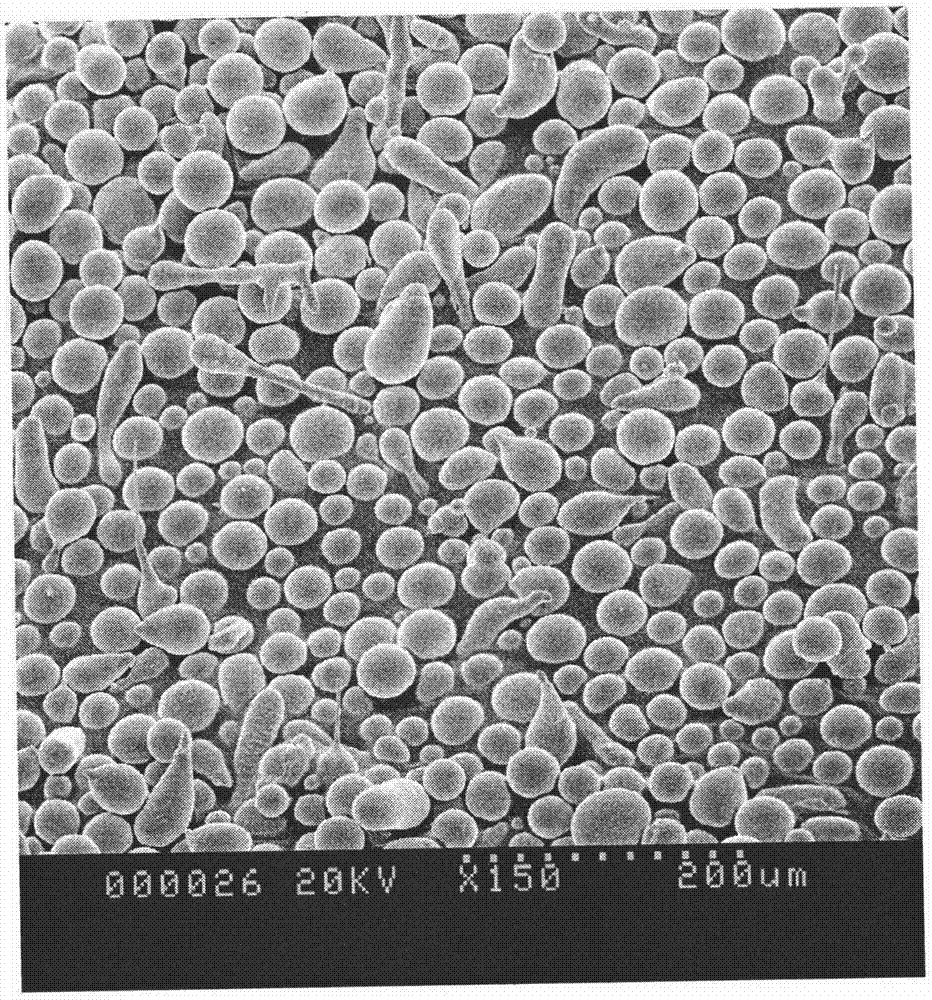

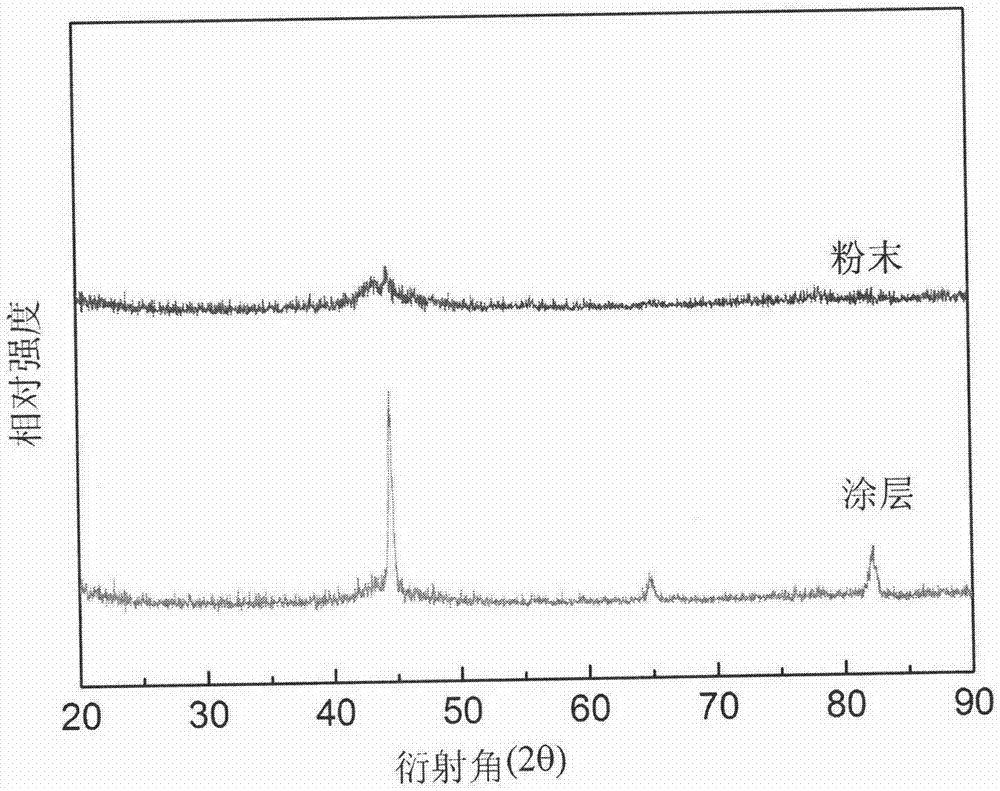

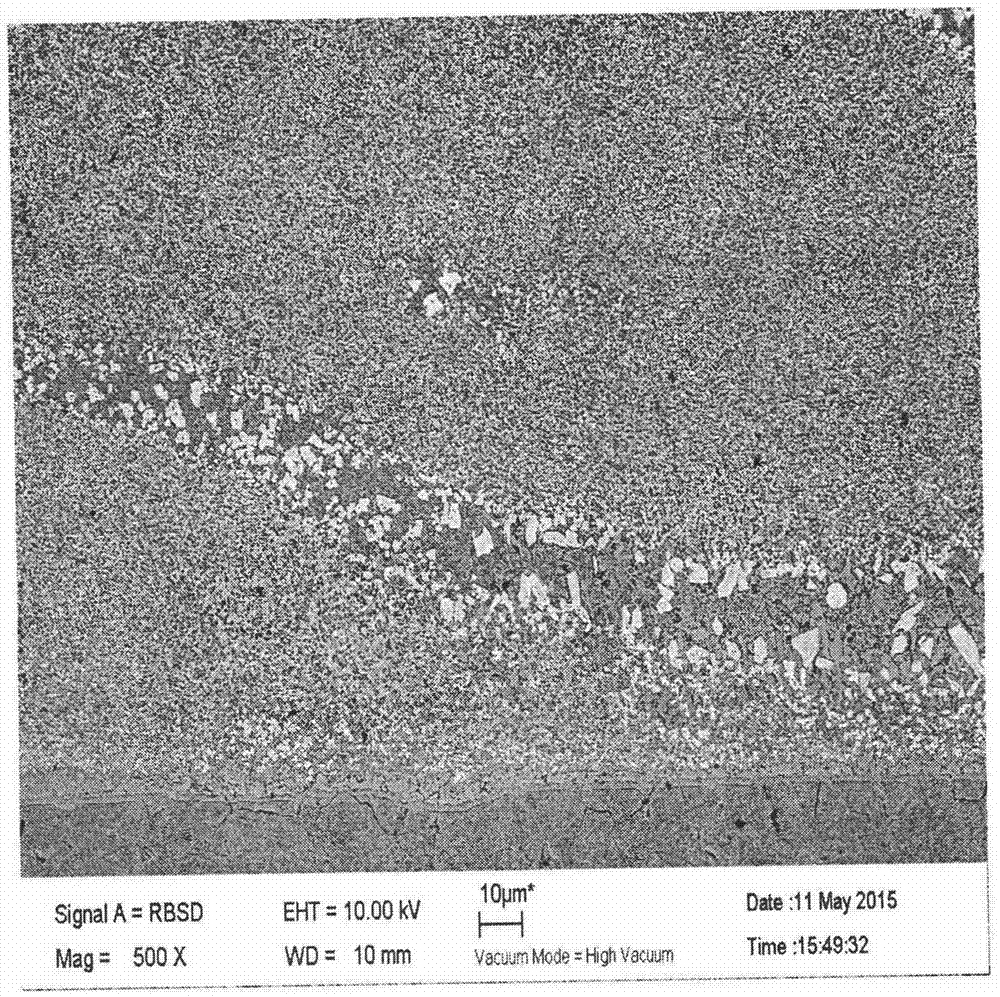

[0030] Iron-based amorphous powder was prepared by high-frequency vacuum induction furnace (graphite crucible) and close-coupled gas atomization powder making equipment. Vacuum the high-frequency vacuum induction furnace cavity to 10 -2 Below Pa, the metals Fe, Cr, Mn, Mo, W, B, C and Si are weighed and prepared according to the nominal mass fraction, and then put into a graphite crucible, and cast after they are fully melted and uniform. To ensure uniform distribution of elements, remelt the ingot once. Put the ingot into the alumina crucible and place it together in a vacuum chamber, evacuate to 5Pa and heat up. After the alloy is fully melted, atomize at a superheat of 100°C. The atomization medium used is argon. The air ...

Embodiment 2

[0040] Embodiment 2: The differences between this embodiment and Embodiment 1 are: the single-pass laser cladding process parameters are 2000W, the spot width is 6mm, and the scanning speed is 10mm / s. Others are the same as Embodiment 1. Under the process conditions, the amorphous coating can be obtained with a dense coating structure, no cracks and hole defects, good bonding between the substrate and the cladding layer, and no significant change in wear resistance and corrosion resistance.

Embodiment 3

[0041] Embodiment 3: The differences between this embodiment and Embodiment 1 are: the process parameters of single-pass laser cladding are 2000W, the spot width is 8mm, and the scanning speed is 8mm / s. Others are the same as Embodiment 1. Under the process conditions, the amorphous coating can be obtained with a dense coating structure, no cracks and hole defects, good bonding between the substrate and the cladding layer, and no significant change in wear resistance and corrosion resistance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com