Preparation method for non-stoichiometric ratio type nanometer VO2-x powder for regulating and controlling phase transition temperature

A non-stoichiometric, phase transition temperature technology, applied in the fields of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, which can solve the problems of high cost, high equipment requirements, and thermally induced phase transition properties of vanadium dioxide. Reducing problems such as mild reaction conditions, breaking through application bottlenecks, and short production cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

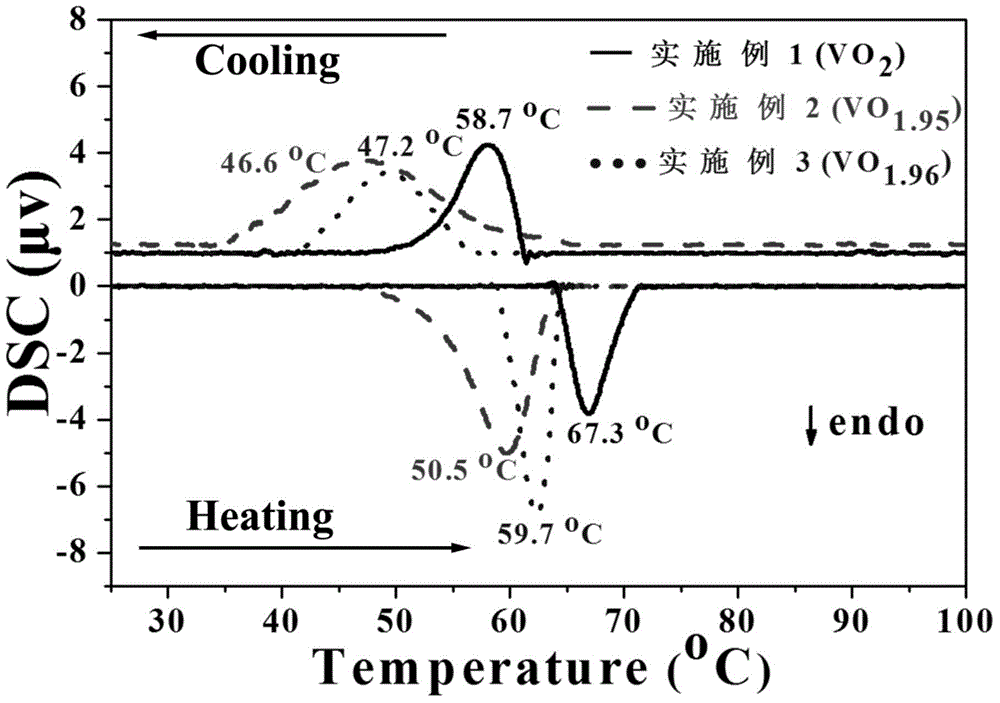

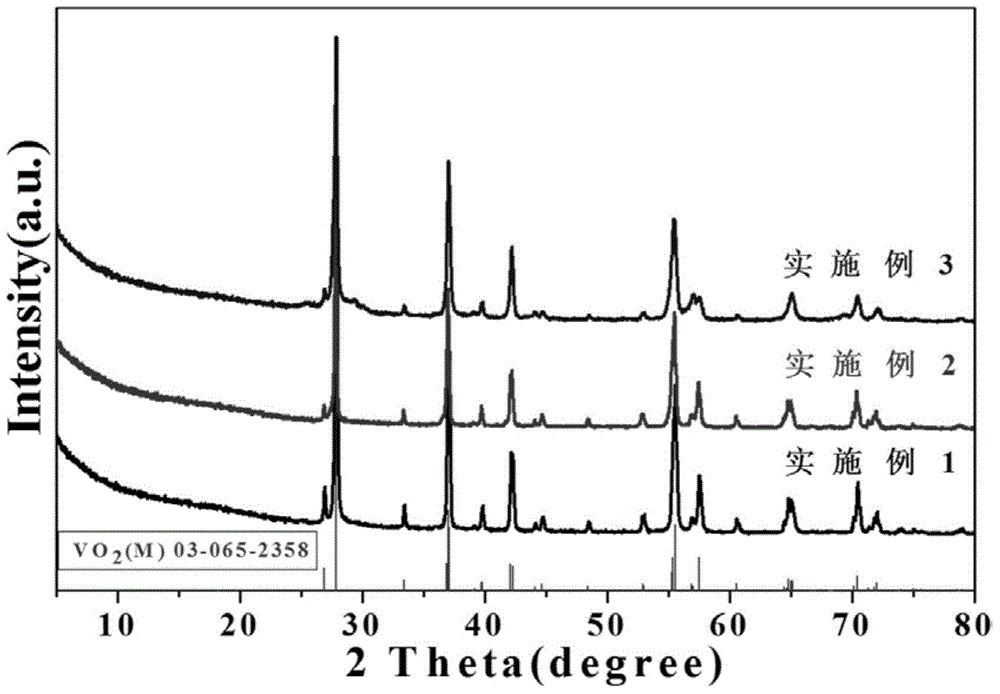

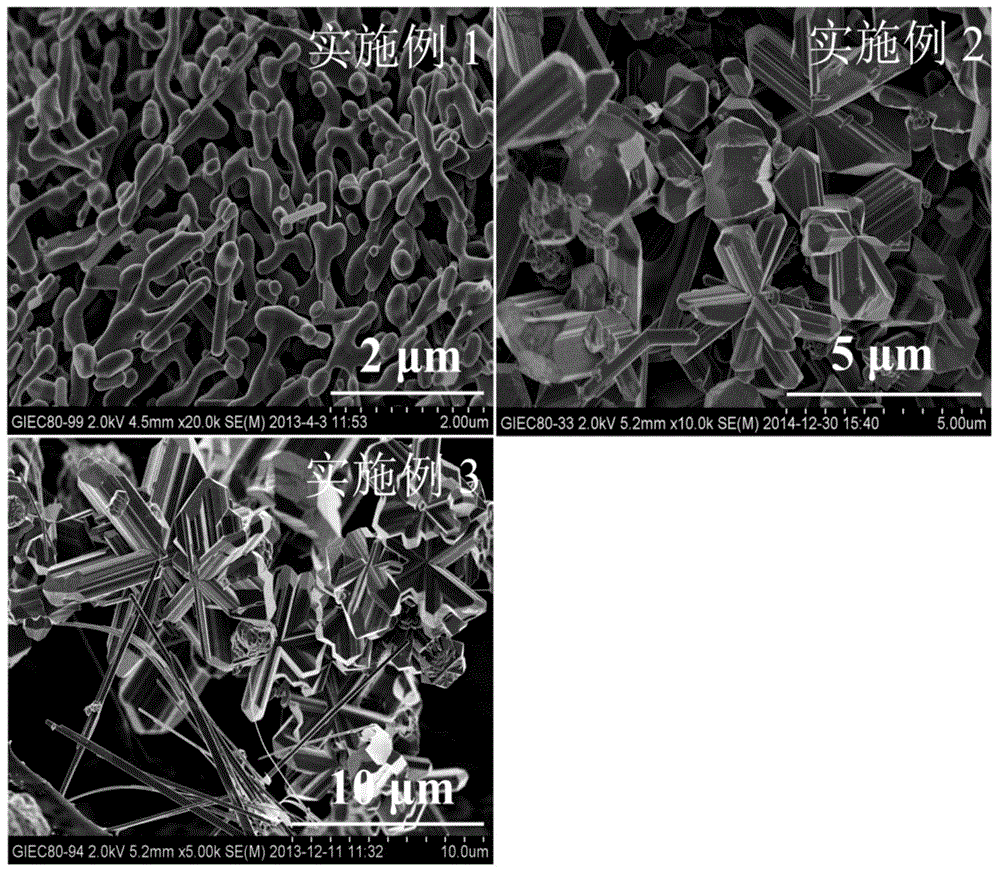

Embodiment 1

[0023] Add 1.891g of oxalic acid to the beaker, add 75mL of deionized water, and stir magnetically in a water bath at a constant temperature of 30°C for 15 minutes. Stir for 0.5h, put the above-mentioned precursor into the reaction kettle, conduct a hydrothermal reaction at 160°C for 48h, centrifuge the product, wash it with a mixture of absolute ethanol and deionized water with a volume ratio of 1:2, and then put it into vacuum drying The oven was treated at 60°C for 4 hours, and the dried samples were put into the furnace for annealing treatment, and the protective atmosphere was introduced: argon gas 0.5L / min; heat treatment conditions: 30°C heating for 94min to 500°C, constant temperature for 1h, natural cooling in the furnace to room temperature to obtain VO with a phase transition temperature of 63.0°C 2.0 Powder. The phase transition parameters are shown in Table 1, and the differential scanning calorimetry (DSC) spectrum is shown in figure 1 The X-ray diffraction (XR...

Embodiment 2

[0027] Add 1.891g of oxalic acid to the beaker, add 75mL of deionized water, and stir magnetically in a water bath at a constant temperature of 30°C for 15 minutes. Stir for 1 hour, put the above-mentioned precursor into the reaction kettle, conduct a hydrothermal reaction at 280°C for 48 hours, centrifuge the product, wash it with a mixture of absolute ethanol and deionized water with a volume ratio of 1:3, and then put it in a vacuum drying oven Treat at 60°C for 4 hours, put the dried samples into the furnace for annealing treatment, and introduce a protective atmosphere: high-purity nitrogen 0.5L / min; heat treatment conditions: 30°C heating for 114min to 600°C, constant temperature for 2h, natural cooling in the furnace to room temperature to obtain VO with a phase transition temperature of 53.5°C 1.95 Powder. The phase transition parameters are shown in Table 1, and the differential scanning calorimetry (DSC) spectrum is shown in figure 1 The X-ray diffraction (XRD) pat...

Embodiment 3

[0029] Add 1.891g of oxalic acid to the beaker, add 75mL of deionized water, stir in a water bath at a constant temperature of 30°C for 15 minutes, add 2.445g of vanadyl sulfate to the above solution, stir in a water bath at a constant temperature of 30°C for 10 minutes, adjust the temperature of the water bath to 100°C, and stir at a constant temperature 2h, put the above-mentioned precursor into the reaction kettle, hydrothermally react at 280°C for 48h, centrifuge the product, wash it with a mixture of absolute ethanol and deionized water with a volume ratio of 1:5, and then put it in a vacuum drying oven for 60 ℃ treatment for 4 hours, and naturally cooled to room temperature to obtain VO with a phase transition temperature of 55.8℃ 1.96 Powder. Its phase transition parameters are shown in Table 1, and the differential scanning calorimetry (DSC) spectrum is shown in figure 1 The X-ray diffraction (XRD) pattern is shown as figure 2 As shown, the scanning electron microsc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Phase transition temperature | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com