Method for improving bismuth ferrotitanium oxide nano-powder aggregation

A nano-powder and oxide technology, which is applied in the direction of iron compounds, chemical instruments and methods, nanotechnology, etc., can solve the problem of improving agglomeration, difficult to inhibit the agglomeration of powder particles, and expand the distance between grains, so as to improve the problem of agglomeration , good monodispersity, improve the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] 1.1 Sample preparation:

[0054] Provide 50mL of acetic acid solution with a mass concentration of 0.39% (concentration of acetic acid with a concentration of 98% and water in a volume ratio of 4:1000), while stirring, slowly add Bi prepared by the co-precipitation method 7 Fe 3 Ti 3 O 21 0.1g nano powder to obtain a suspension; seal the obtained suspension and perform low-speed magnetic stirring at a rotation speed of 200r / min for 3h to obtain a mixed liquid; place the obtained mixed liquid in an ultrasonic disperser for ultrasonic dispersion for 1 hour (60W, 50KHz , 28°C), to obtain a dispersion; centrifuge the obtained dispersion at a high speed of 10000r / min, and then wash with deionized water to a pH of about 7 to remove the supernatant to obtain a solid washing; place the obtained solid washing After mixing well in 50mL deionized water, it is freeze-dried. After the ice cubes sublimate, Bi with good monodispersity with significantly reduced agglomeration is obtained 7...

Embodiment 2

[0063] It was carried out according to the dispersion method of Example 1, except that the concentration of the acetic acid solution was 1.92% (the acetic acid with a concentration of 98% and water were prepared at a volume ratio of 20:1000).

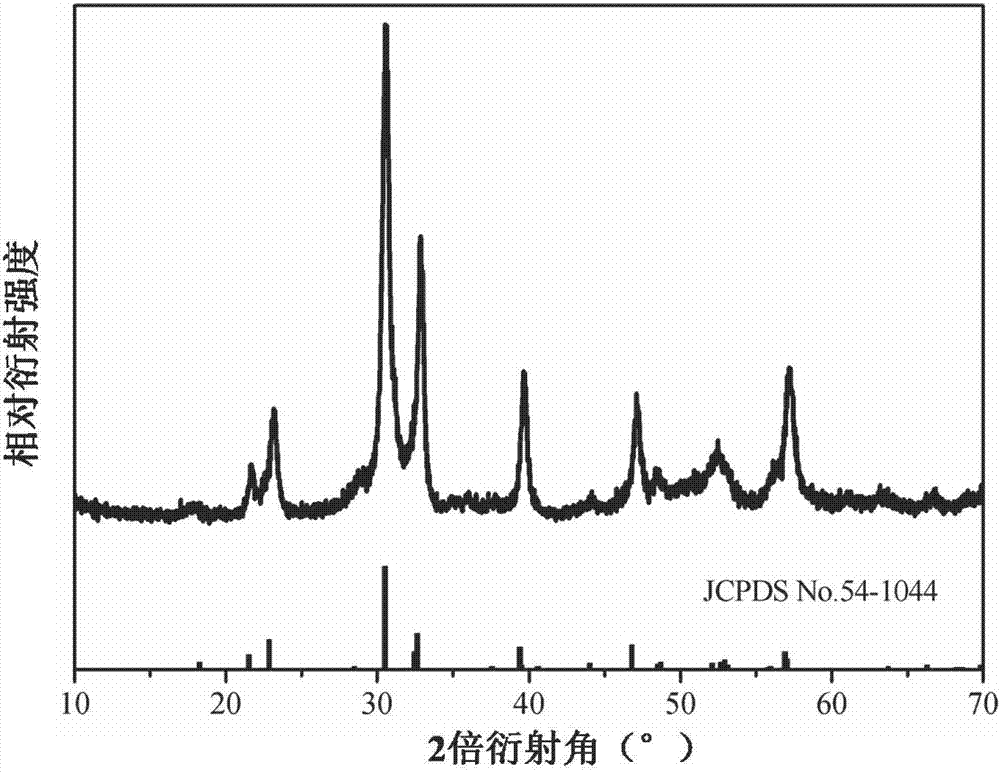

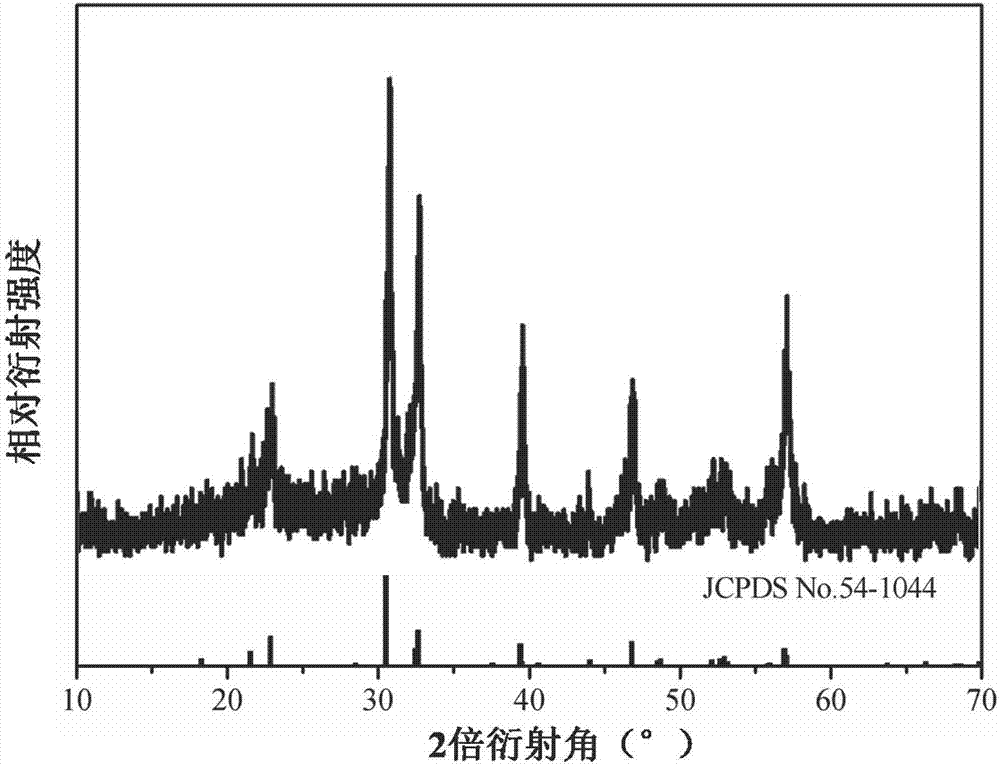

[0064] The sample was subjected to X-ray diffraction test according to the characterization method of Example 1. The results showed that before and after the dispersion treatment, the X-ray pattern of the sample was consistent with the standard pattern, and the substance was relatively pure, which proved that the dispersion treatment of the present invention has not changed and Destroy Bi 7 Fe 3 Ti 3 O 21 The crystal structure of nanoparticles.

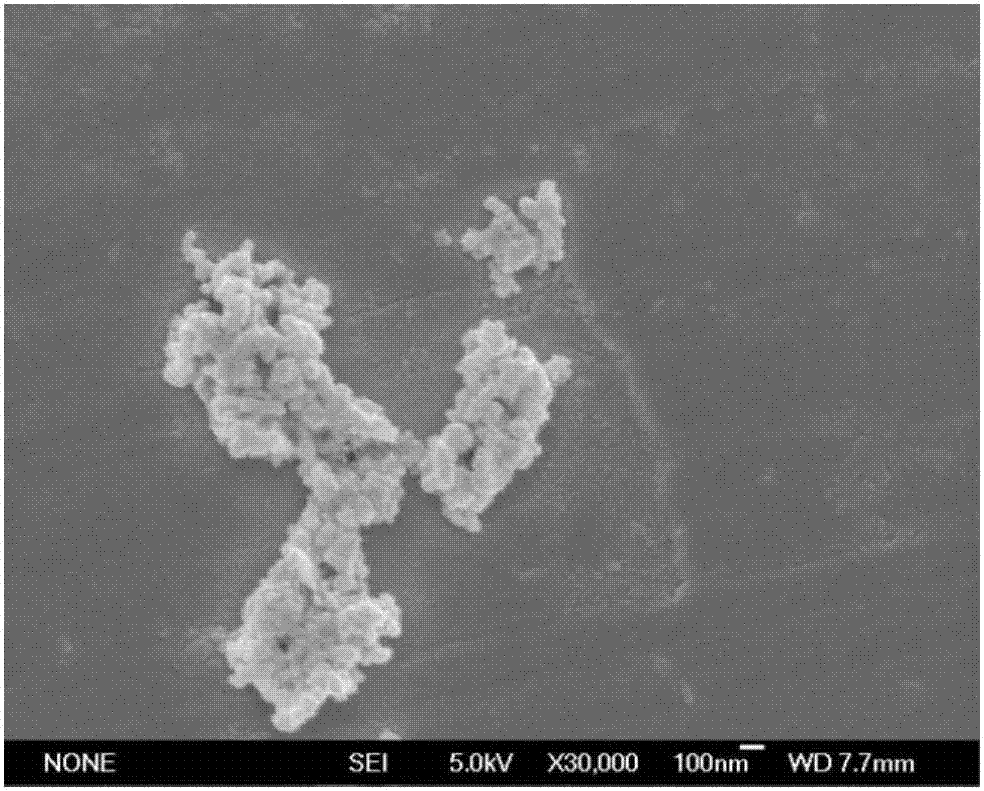

[0065] Scanning electron microscopy (SEM) test was performed on the sample according to the characterization method of Example 1. The results showed that after the dispersion method of the present invention was implemented, the obtained Bi 7 Fe 3 Ti 3 O 21 In the nano-powder, the phenomenon of partic...

Embodiment 3

[0067] Follow the dispersion method in Example 1, except that the acetic acid solution is replaced with a hydrochloric acid solution.

[0068] The sample was subjected to X-ray diffraction test according to the characterization method of Example 1. The results showed that before and after the dispersion treatment, the X-ray pattern of the sample was consistent with the standard pattern, and the substance was relatively pure, which proved that the dispersion treatment of the present invention has not changed and Destroy Bi 7 Fe 3 Ti 3 O 21 The crystal structure of nanoparticles.

[0069] Scanning electron microscopy (SEM) test was performed on the sample according to the characterization method of Example 1. The results showed that after the dispersion method of the present invention was implemented, the obtained Bi 7 Fe 3 Ti 3 O 21 In the nano-powder, the phenomenon of particle agglomeration has been significantly improved, and the crystal grains with a size of about 100 nm exist in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com