Preparation method of low-temperature cured nitride red phosphor paste

A red phosphor and nitride technology, applied in chemical instruments and methods, luminescent materials, etc., can solve problems such as narrow application range, and achieve the effects of simple equipment, convenient use and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

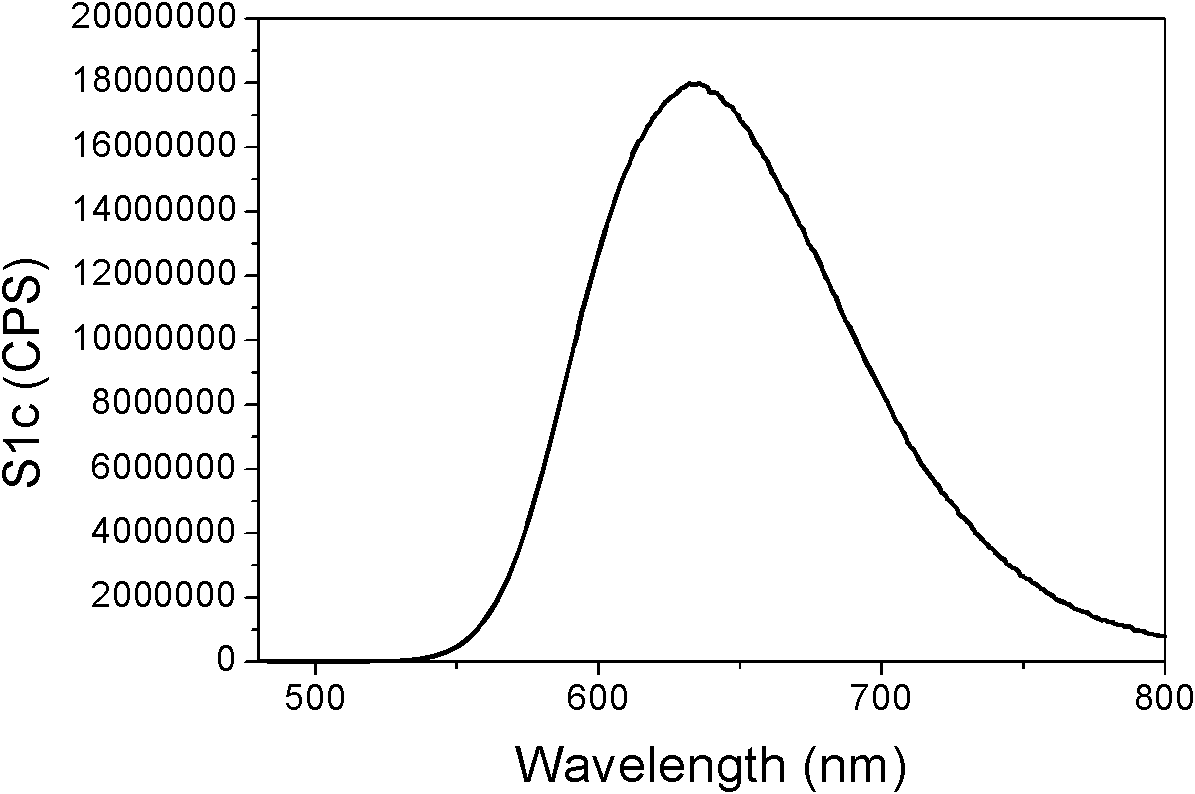

Image

Examples

Embodiment 1

[0019] First, the metal M nitride, europium nitride and silicon nitride are mixed according to the atomic number ratio M:Eu:Si=(2-x):x:5 (M=Ca, Sr, Ba), where x = 0.5. After mixing evenly, calcinate at 1400-1600°C for 15 hours under a nitrogen atmosphere; ball mill after calcining, and obtain nitride red phosphor powder M after ball milling 1.5 Eu 0.5 Si 5 N 8 (M=Ca, Sr, Ba) powder particle size 1~25μm;

[0020] Then, under constant temperature conditions of 70° C., 5 grams of vinyl acetate resin was dissolved in 40 grams of ethylene glycol ether and 5 grams of terpineol until completely dissolved, and filtered to obtain an organic vehicle;

[0021] Finally, add 30 grams of nitride red fluorescent powder prepared in step 1), 0.1 gram of polyethylene wax dispersant, and 1.5 gram of γ-aminopropyltriethoxysilane thickener to 20 grams of the above-mentioned organic carrier, and mix well , After filtering through 200 meshes, the low-temperature curing nitride red phosphor slur...

Embodiment 2

[0024]Step 1): Mix metal M nitride, europium nitride and silicon nitride according to the atomic number ratio M:Eu:Si=(2-x):x:5, where x=0.2; after mixing evenly, Calcined at 1400-1600°C for 8 hours in a nitrogen atmosphere; ball milled after calcination, and obtained nitride red phosphor powder M after ball milling 1.8 Eu 0.2 Si 5 N 8 (M=Ca, Sr, Ba) particle size 1~25μm;

[0025] Step 2): under the constant temperature condition of 80°C, 15 grams of vinyl acetate resin was dissolved in 35 grams of ethylene glycol ether according to the mass percentage, until it was completely dissolved, and the organic carrier was obtained by filtration;

[0026] Step 3): Add 30 grams of nitride red fluorescent powder prepared in step 1), 0.5 grams of zinc stearate dispersant, and 0.5 grams of vinyl tris (β-methoxyethoxy) silane thickener to 25 grams of the above-mentioned In the organic carrier, mix evenly, and filter through 200 mesh to obtain low-temperature curing nitride red phosphor...

Embodiment 3

[0028] Step 1): Mix metal M nitride, europium nitride and silicon nitride according to the atomic number ratio M:Eu:Si=(2-x):x:5, where x=1; after mixing evenly, Calcined at 1400-1600°C for 20 hours under a nitrogen atmosphere; ball milled after calcination, and obtained nitride red phosphor powder M after ball milling 1 Eu 1 Si 5 N 8 (M=Ca, Sr, Ba) particle size 1~25μm;

[0029] Step 2): under the constant temperature condition of 90°C, 10 grams of vinyl acetate resin was dissolved in 30 grams of ethylene glycol ether and 10 grams of terpineol according to the mass percentage until it was completely dissolved, and the organic carrier was obtained by filtration;

[0030] Step 3): Add 40 grams of nitride red fluorescent powder prepared in step 1), 1.0 grams of microcrystalline paraffin dispersant, and 1.5 grams of di(dioctylpyrophosphoryl) oxyacetate titanium thickener to 16 grams of the above-mentioned In the organic carrier, mix evenly, and filter through 200 mesh to obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com