A method for preparing nano-titanium dioxide with high photocatalytic activity by using waste wool

A nano-titanium dioxide, catalytic activity technology, applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc., to achieve the effect of strong photocatalytic activity, simple preparation process, and prevention of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

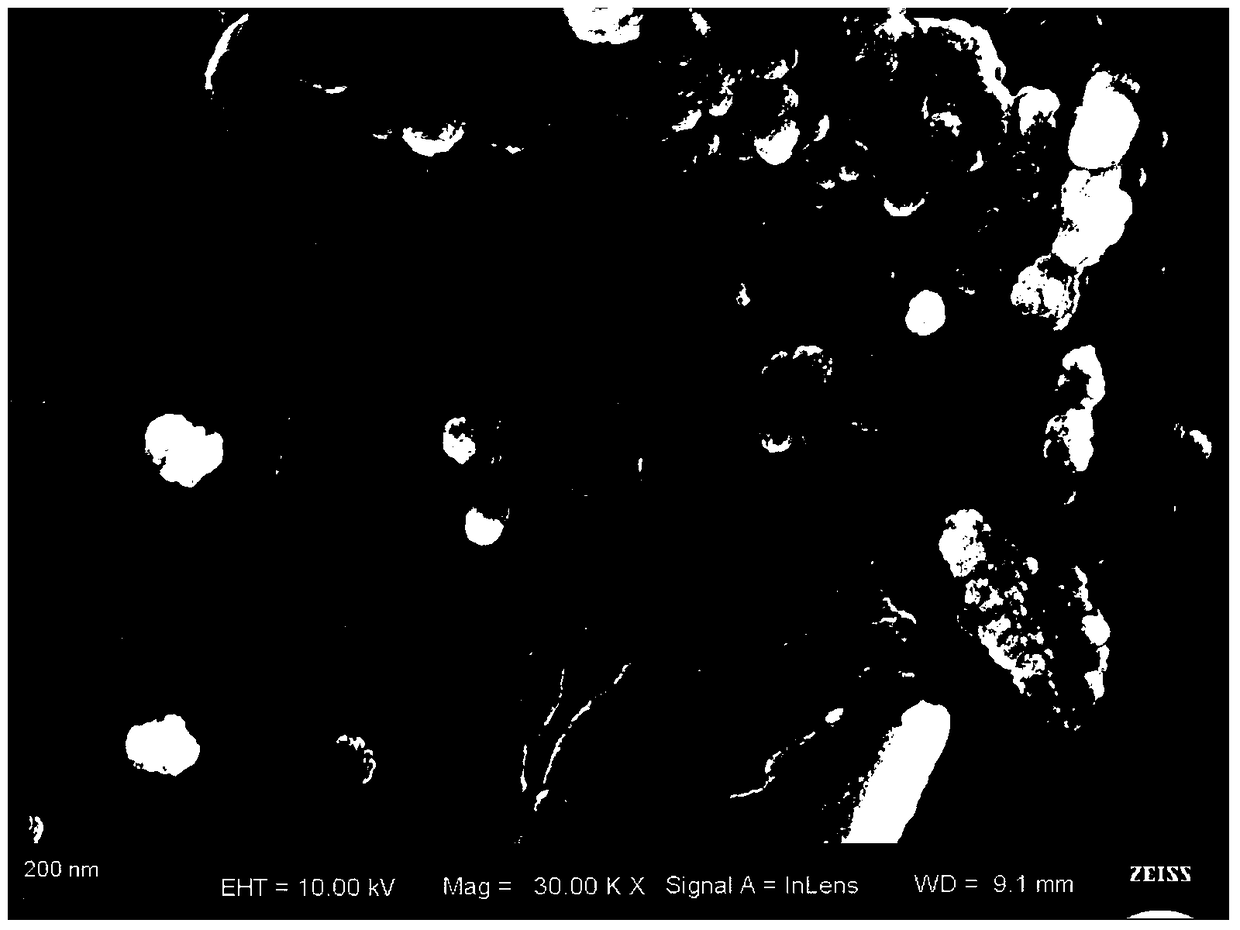

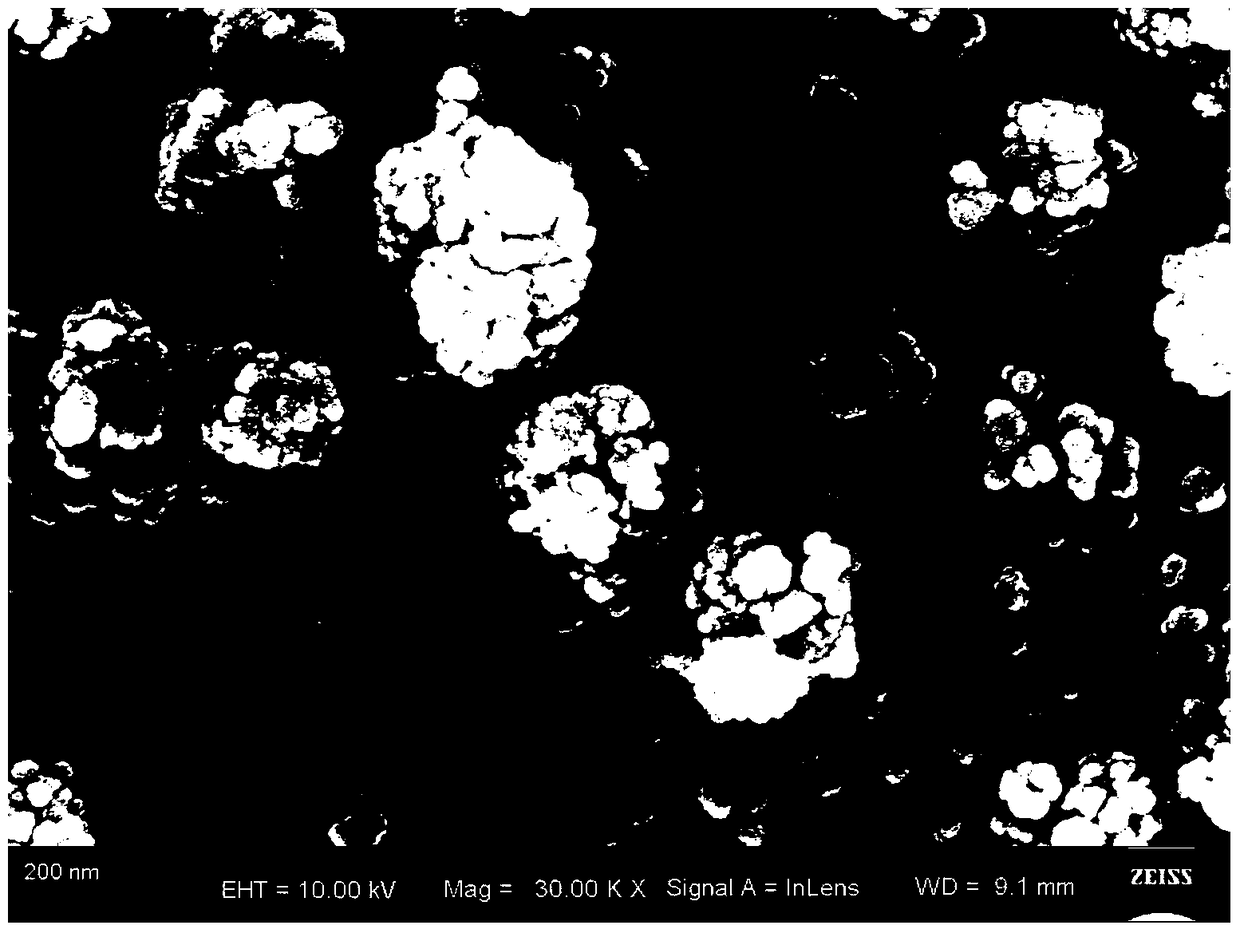

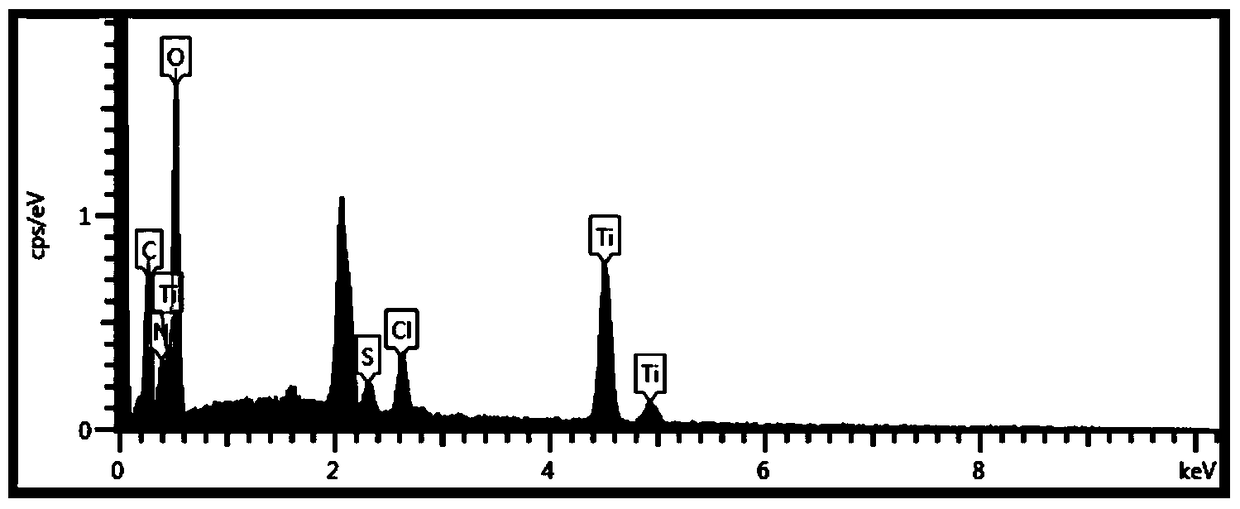

Embodiment 1

[0047] Measure 5mL of tetrabutyl titanate and dissolve it in 5mL of absolute ethanol solution, and keep stirring, then slowly add 70mL of deionized water and stir rapidly to form a white milky transparent solution Adjust the pH value of the solution with hydrochloric acid is 1. According to the bath ratio of 1:30, weigh waste wool, and prepare it with 30% hydrogen peroxide 10ml / L, sodium carbonate 0.5g / L and sodium silicate 0.5g / L at 50°C and pH value 8.5. The mixed solution was treated for 30 minutes, then soaked in 30°C absolute ethanol solution for 10 minutes, rinsed once with deionized water, and finally dried at 80°C. Cut the washed wool into short fibers with a length less than 5mm with a rotary twisting knife type fiber cutter. Weigh short wool fibers according to 1% of the amount of tetrabutyl titanate, add them to the precursor solution, soak them for 5 minutes, and transfer them to a high-temperature and high-pressure reactor. The volume of the solution accounts for...

Embodiment 2

[0049] Measure 5mL of tetrabutyl titanate and dissolve it in 5mL of absolute ethanol solution, and keep stirring, then slowly add 70mL of deionized water and stir rapidly to form a white milky transparent solution Adjust the pH value of the solution with hydrochloric acid for 2. According to the bath ratio of 1:50, weigh a certain amount of waste wool, and prepare it with 30% hydrogen peroxide 20ml / L, sodium carbonate 2g / L and sodium silicate 2g / L at 60°C and pH value 9.5. The resulting mixed solution was treated for 50 minutes, then soaked in 50°C absolute ethanol solution for 20 minutes, rinsed with deionized water for 3 times, and finally dried at 110°C. Cut the washed wool into short fibers with a length less than 5mm with a rotary twisting knife type fiber cutter. Weigh short wool fibers according to 10% of the amount of tetrabutyl titanate, add them to the precursor solution, soak them for 10 minutes, and then transfer them to a high-temperature and high-pressure reacto...

Embodiment 3

[0051] Measure 5mL of tetrabutyl titanate and dissolve it in 5mL of absolute ethanol solution, and keep stirring, then slowly add 70mL of deionized water and stir rapidly to form a white milky transparent solution Adjust the pH value of the solution with hydrochloric acid is 1.5. According to the bath ratio of 1:40, weigh a certain amount of waste wool, and use 15ml / L of hydrogen peroxide with a mass concentration of 30%, 1.5g / L of sodium carbonate, and 1g / L of sodium silicate at 55°C and a pH value of 9. The prepared mixed solution was treated for 40 minutes, then soaked in 40°C absolute ethanol solution for 15 minutes, rinsed twice with deionized water, and finally dried at 100°C. Cut the washed wool into short fibers with a length less than 5mm with a rotary twisting knife type fiber cutter. Weigh short wool fibers according to 6% of the amount of tetrabutyl titanate, add them to the precursor solution, soak them for 8 minutes, and transfer them to a high-temperature and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com