Preparation method of positive electrode material, water-based zinc ion battery positive electrode and application

A positive electrode material and dual-ion technology, applied in the field of aqueous zinc-ion batteries, can solve problems such as poor ion diffusion kinetics, poor cycle performance and rate capability, unstable structure, etc., and achieve low price, good cycle performance and rate performance, The effect of low doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A method for preparing a dual-ion co-doped vanadium pentoxide positive electrode material of the present invention comprises the following steps:

[0045] S1, put V 2 o 5 Powder, two soluble doping metal salts are mixed and then added H 2 o 2 solution and stirred until the end of the reaction;

[0046] will V 2 o 5 The concentration of the mixed solution is controlled to be 0.05~0.09mol / L, and the molar ratio of the two kinds of soluble doping metal salts is 1:(1~5); the two kinds of soluble doping metal salts and V 2 o 5 The molar ratio of feeding is 1:(8~12).

[0047] Preferably, the stirring time of the mixed solution is controlled within 40-60 minutes.

[0048] The soluble doping metal salt is one or more of nickel acetate, zinc acetate, manganese acetate, magnesium acetate, lithium acetate, sodium acetate and calcium acetate.

[0049] S2. Transfer the mixed liquid to a hydrothermal kettle for hydrothermal reaction, keep it warm at 180-220°C for 46-50 hours...

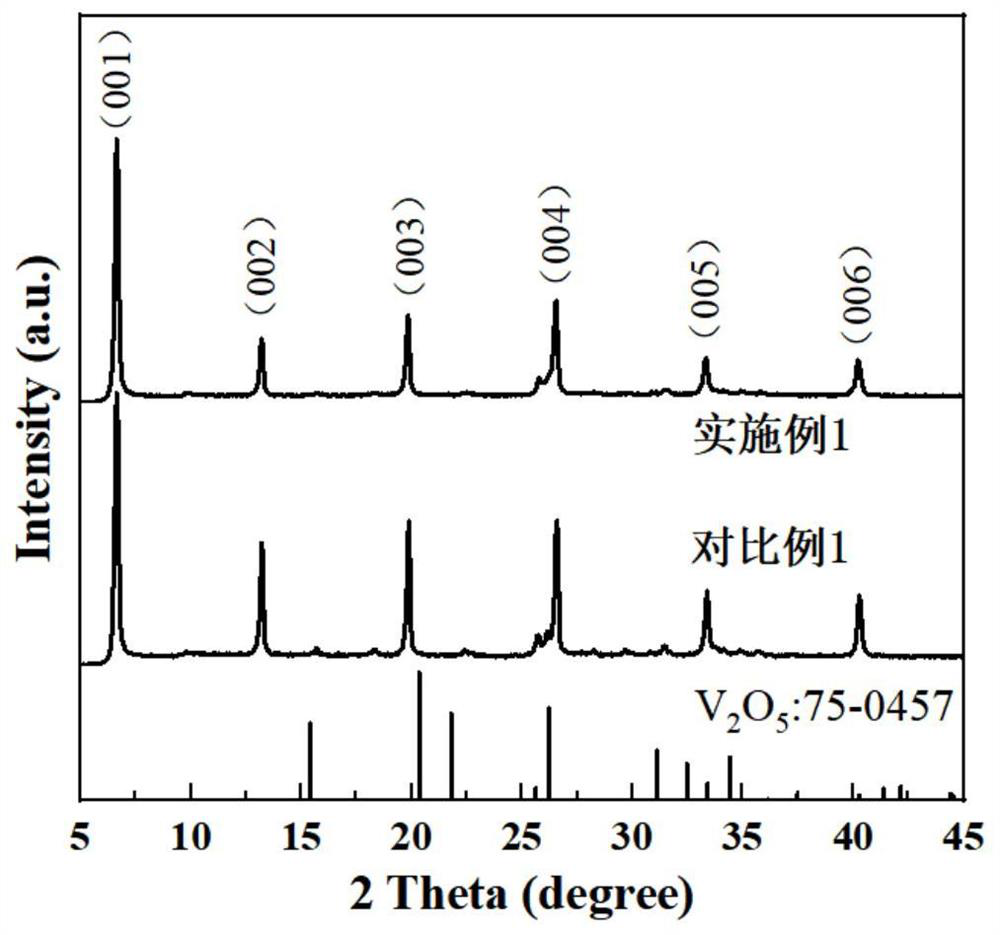

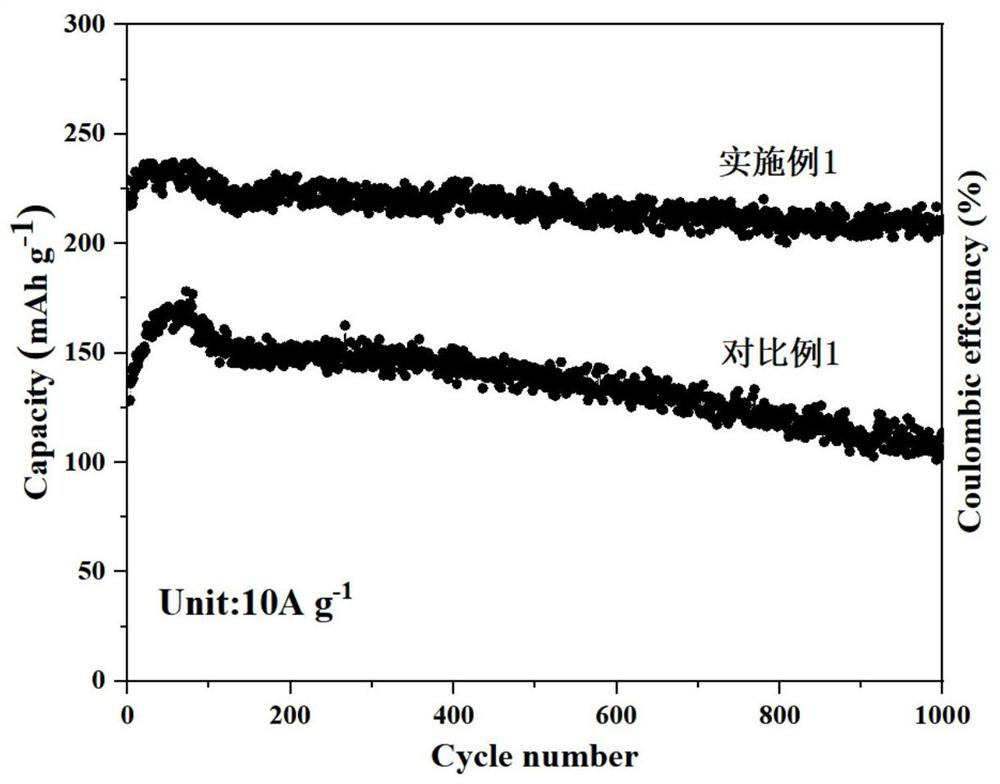

Embodiment 1

[0057] 1. Weigh the raw material 3mmol V 2 o 5 The powder was dissolved in 24mL of deionized water, and the raw material 0.25mmol Mg(CH 3 COO) 2 4H 2 O crystals and 0.25mmol Zn(CH 3 COO) 2 2H 2 O crystals were respectively dissolved in 10 mL of deionized water, placed on a magnetic stirrer and stirred for 1 h;

[0058] 2. In the well-stirred V 2 o 5 Add dropwise 6mL mass fraction of 30% hydrogen peroxide solution in the aqueous solution, continue to stir on the magnetic stirrer for 40min, after that the Mg(CH 3 COO) 2 4H 2 O crystals and Zn(CH 3 COO) 2 2H 2 The O crystal mixed solution is added dropwise to obtain a precursor solution;

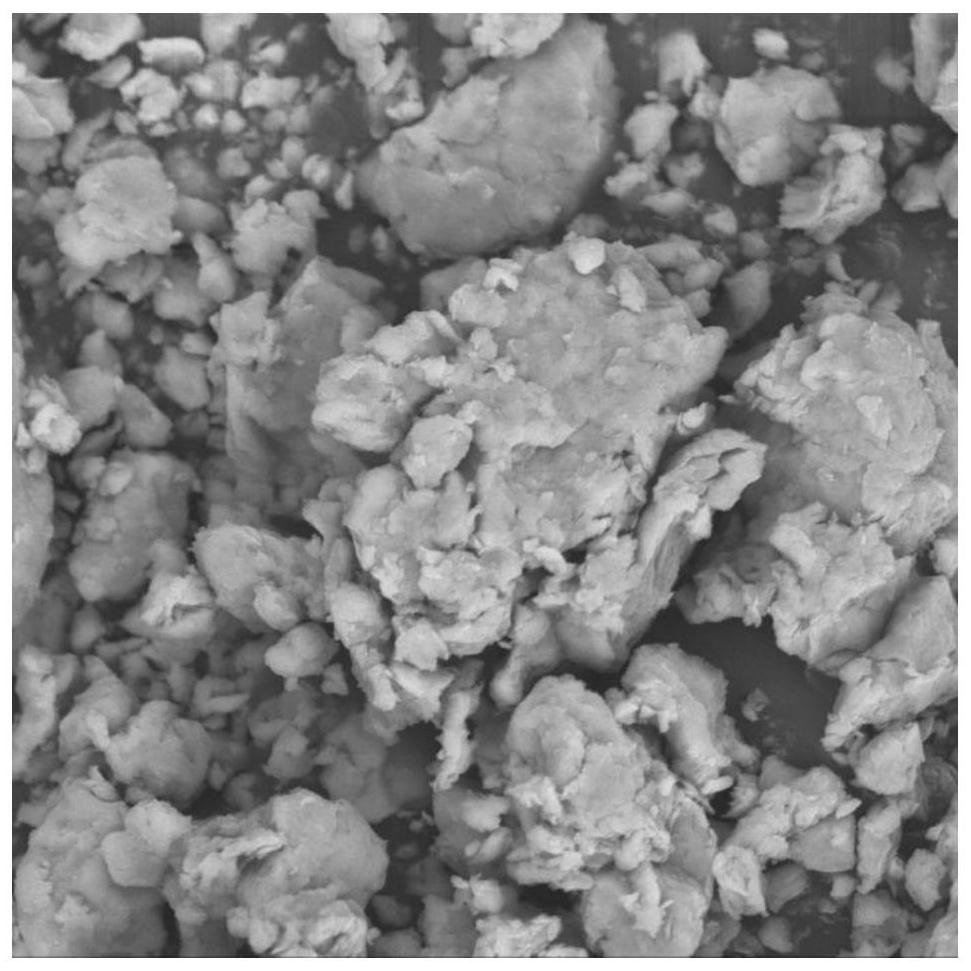

[0059] 3. Add the obtained solution into a hydrothermal kettle, put the hydrothermal kettle into an oven and heat it to 180°C for 48 hours. After the hydrothermal reaction is completed, cool it down to room temperature naturally, collect the product in the hydrothermal kettle, filter, and centrifuge and wash 3 times , vacuum dryi...

Embodiment 2

[0061] 1. Weigh the raw material 2.75mmol V 2 o 5 Dissolve the powder in 24mL of deionized water, weigh 0.25mmol CH 3 COOLi·2H 2 O crystals and 0.50 mmol Mg(CH 3 COO) 2 4H 2 O crystals were respectively dissolved in 10 mL of deionized water, placed on a magnetic stirrer and stirred for 1 h;

[0062] 2. In the well-stirred V 2 o 5 Add dropwise 6mL mass fraction of 30% hydrogen peroxide solution in the aqueous solution, continue to stir on the magnetic stirrer for 40min, after that the Mg(CH 3 COO) 2 4H 2 O crystals and CH 3 COOLi·2H 2 The O crystal mixed solution is added dropwise to obtain a precursor solution;

[0063] 3. Add the obtained solution into a hydrothermal kettle, put the hydrothermal kettle into an oven and heat it to 200°C for 48 hours. After the hydrothermal reaction is completed, cool it down to room temperature naturally, collect the product in the hydrothermal kettle, filter it, and wash it twice by centrifugation , vacuum drying at 90° C. for 8 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com