Lithium-rich manganese-based/graphene composite cathode material, preparation method thereof and application thereof

A graphene composite, lithium-rich manganese-based technology, applied in the direction of positive electrodes, battery electrodes, active material electrodes, etc., can solve the problems of poor rate performance, high cost, and large structural influence of lithium-rich manganese-based materials, and achieve the goal of promoting Charge and discharge process and rate performance, preparation method and performance improvement, and the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

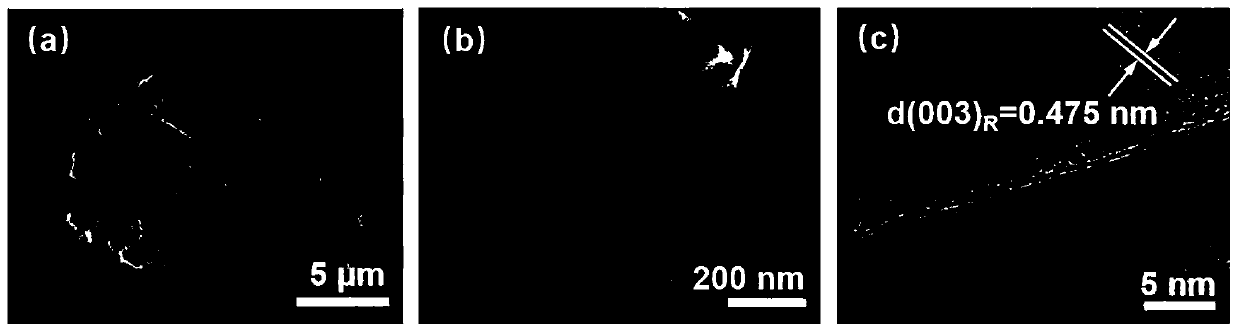

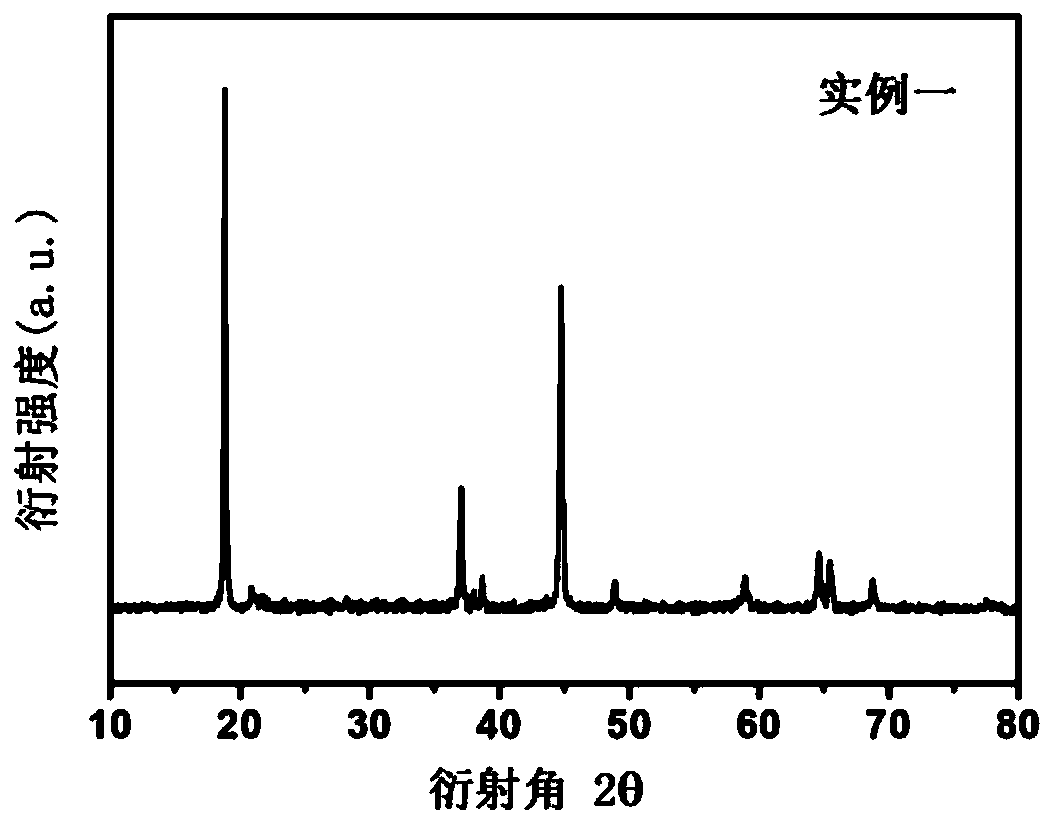

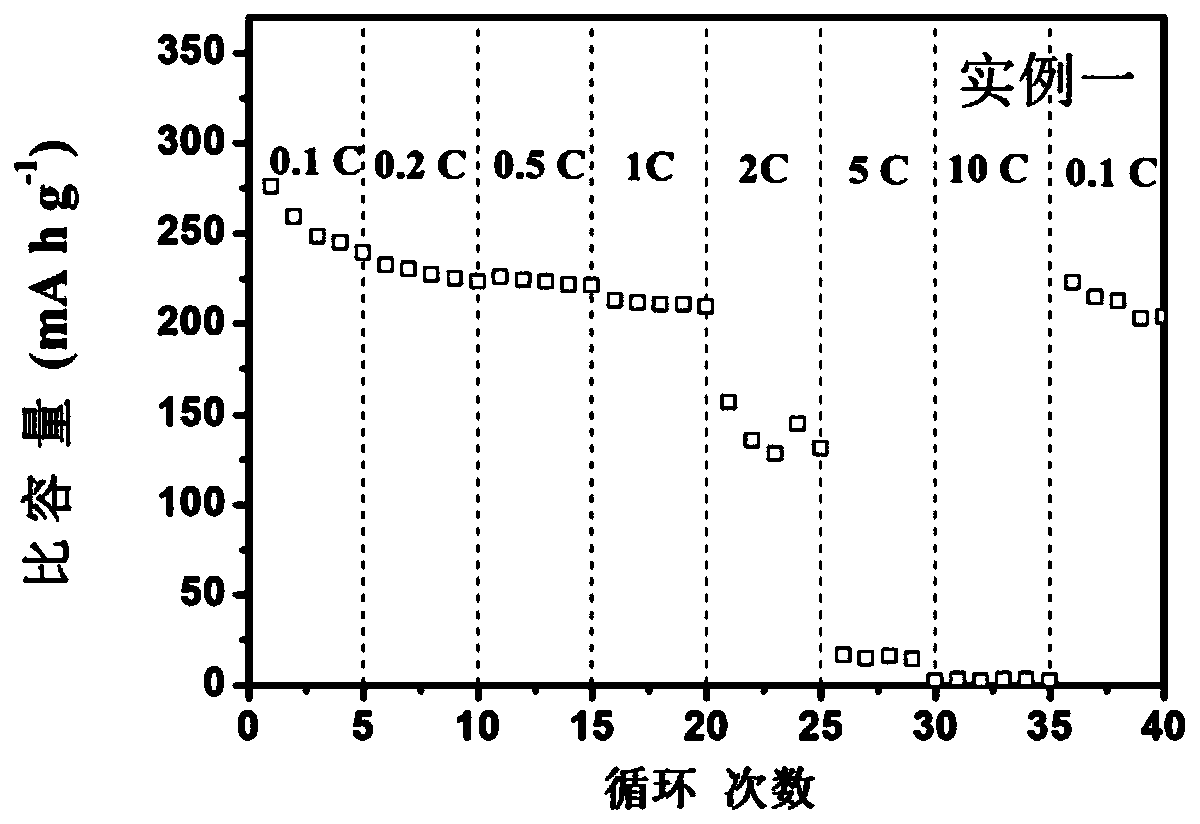

Embodiment 1

[0035] 1) Weigh nickel sulfate, cobalt sulfate, and manganese sulfate, dissolve them in deionized water in turn, and stir magnetically until 2mol / L MSO is formed. 4 Solution A (M=Mn, Ni, Co, wherein the molar ratio of Mn:Ni:Co is 0.58:0.2:0.05) is set aside.

[0036] 2) Add 100ml of deionized water in the reaction kettle as the bottom liquid, respectively control the flow rate of solution A, 0.83mol / L sodium carbonate solution and 0.37mol / L ammonia water to be 1ml / min, and feed together, in an inert atmosphere , kept the temperature at 50°C, and reacted for 12h under the conditions of pH 8, and washed with absolute ethanol and deionized water after cooling until there was no SO 4 2- , centrifuged, and vacuum-dried to obtain spherical precursor powder.

[0037] 3) The dried MCO 3 powder and lithium carbonate (molecular formula Li 2 CO 3 ) After the powder is ground evenly, put it into the muffle furnace. Under the air atmosphere, raise the temperature to 450°C at a rate of 5...

Embodiment 2

[0043] 1) Weigh 0.15 g of the lithium-rich manganese-based positive electrode material prepared by the co-precipitation method into a ball mill jar, add 4.167 ml of graphene dispersion liquid, and replace step (4) in Example 1 with an appropriate amount of absolute ethanol, and the remaining steps and Example 1 Step 1 is the same, and the lithium-rich manganese-based / graphene composite positive electrode material can be obtained.

[0044] The material prepared in this example has a specific capacity of 249.9 mA·h / g for the first charge and discharge under the condition of 30 mA / g, and a capacity retention rate of 78.98%.

Embodiment 3

[0046] 1) Weigh 0.15 g of the lithium-rich manganese-based positive electrode material prepared by the co-precipitation method into a ball mill jar, add 1.935 ml of graphene dispersion liquid, and replace step (4) in Example 1 with an appropriate amount of absolute ethanol, and the remaining steps and Example 1 Step 1 is the same, and the lithium-rich manganese-based / graphene composite positive electrode material can be obtained.

[0047] The material prepared in this example has a specific capacity of 238.1 mA·h / g for the first charge and discharge under the condition of 30 mA / g, and a capacity retention rate of 45.97%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com