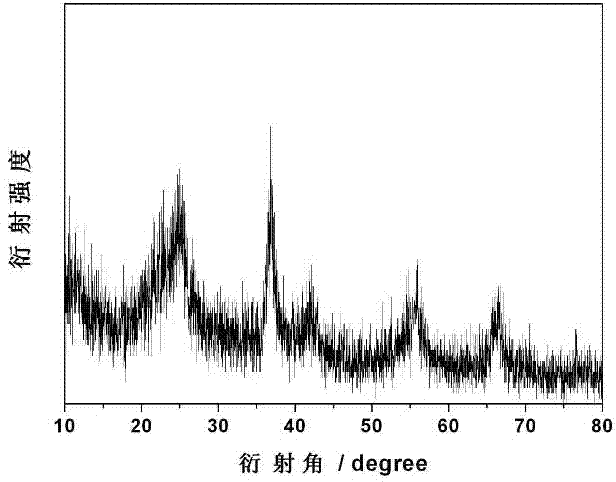

A graphene-loaded flower-like manganese dioxide composite material and its ultrasonic synthesis method

A technology of manganese dioxide and composite materials, which is applied in the field of electrochemistry and material synthesis, can solve the problems of reduced charge and discharge capacity, unstable manganese cycle, and low electronic conductance, and achieve improved capacitance performance, super thermal conductivity and ductility, big yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Embodiment one : Preparation of graphene-loaded flower-like manganese dioxide composites with manganese acetate as manganese source.

[0032] Potassium persulfate (K 2 S 2 o 8 ) 2.5 g, phosphorus pentoxide (P 2 o 5 ) 2.5 g, dissolved in 12 mL of concentrated sulfuric acid, heated to 80°C; then 3 g of natural graphite was added to the above solution, kept at 80°C for 4.5 hours; cooled to room temperature, diluted with 500 mL of deionized water, and left standing overnight ; filter, float residual acid with 0.2 mm filter; dry in a vacuum oven at 60°C; add the obtained preoxide to 120 mL of ice-bathed concentrated sulfuric acid, slowly add 15 g of KMnO under stirring 4 , Keep the temperature below 20°C during the addition process. Then the temperature was controlled at 35°C and stirred for 2 h. Add 250 mL of deionized water to dilute, and keep the temperature below 50°C in an ice bath during the dilution process. Stir for another 2 h, add 0.7 L of deionized water,...

Embodiment 2

[0036] Embodiment two : Preparation of graphene-loaded flower-like manganese dioxide composites with manganese nitrate as manganese source.

[0037]Take 0.259 g of manganese nitrate and add 50 mL of deionized water, add 50 mg of graphene to it, stir for 15 min, ultrasonicate for 0.5 h, add an appropriate amount of 0.3 mol / L hydrochloric acid to it to make the pH of the solution = 1.5, and then stir for 0.5 h. Under ultrasonic conditions, slowly drop 75mL of 9.2 mol / L potassium permanganate solution into the above solution. At 20°C, continue to sonicate for 12h. Centrifuge, wash with alcohol, and wash with water three times each to obtain the product.

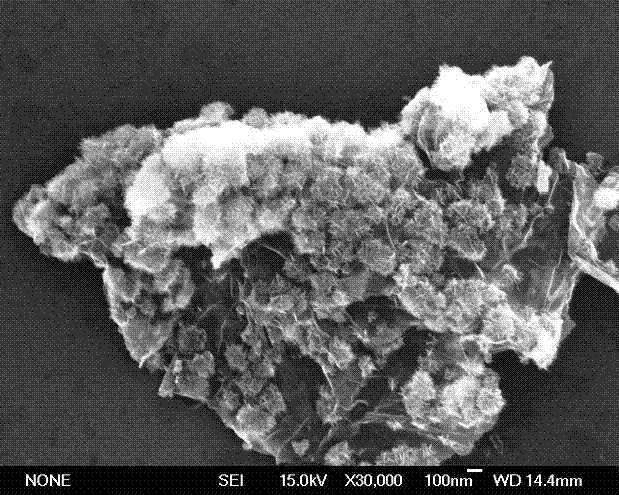

[0038] The scanning electron microscope photograph of the product is shown in figure 2 , it can be seen from the figure that the flower-like manganese dioxide has a size of 200-300 nm and is evenly loaded on the surface of graphene without obvious agglomeration. The prepared material was electrochemically tested, and the ...

Embodiment 3

[0039] Embodiment Three : Preparation of graphene-loaded flower-like manganese dioxide composites with manganese chloride as manganese source.

[0040] Take 0.205g of manganese chloride and add it to 50 mL of deionized water, add 50 mg of graphene to it, stir for 15 min, sonicate for 0.5 h, add an appropriate amount of 0.3 mol / L hydrochloric acid to it to make the pH of the solution = 2.5, and then stir 0.5 h. Under ultrasonication, slowly drop 75 mL of 9.2 mol / L potassium permanganate solution into the above solution. At 50°C, continue to sonicate for 4h. Centrifuge, wash with alcohol, and wash with water three times each to obtain the product.

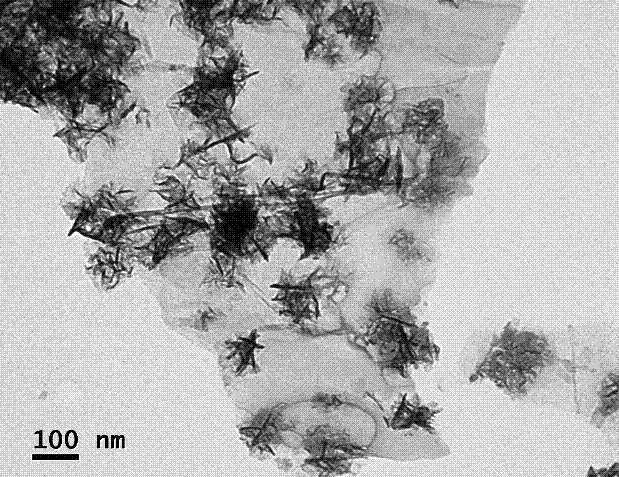

[0041] The transmission electron microscope photograph of the product is shown in image 3 , it can be seen that the flower-like manganese dioxide with a diameter of 100-300 nm is evenly loaded on the surface of graphene, and no obvious agglomeration phenomenon is seen. And several particles are covered by a layer of transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com