A kind of lithium-rich manganese-based solid solution/graphene composite material and preparation method thereof

A lithium-rich manganese-based, composite material technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as poor rate performance, and achieve the effects of short cycle, simple process, and improved rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

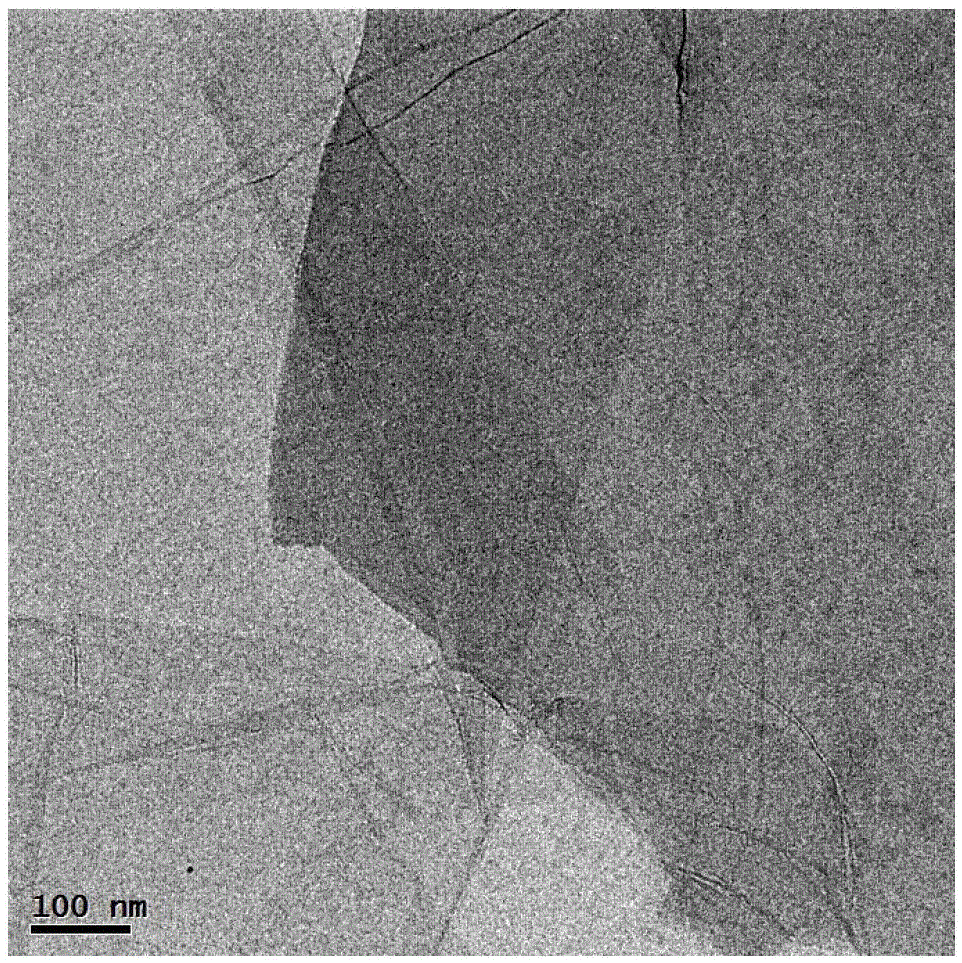

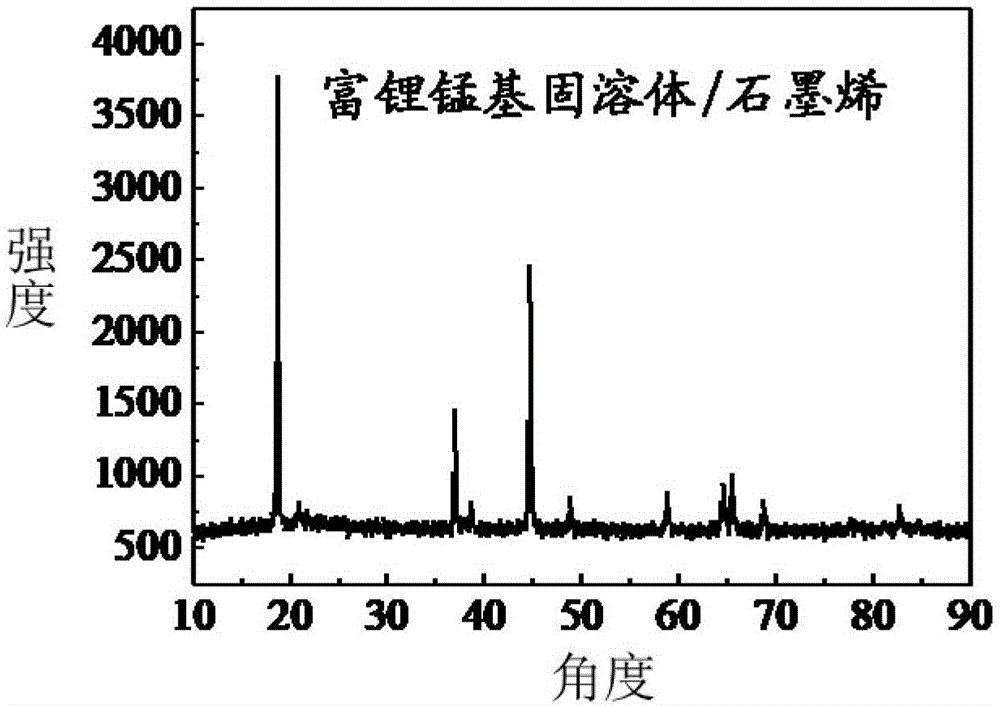

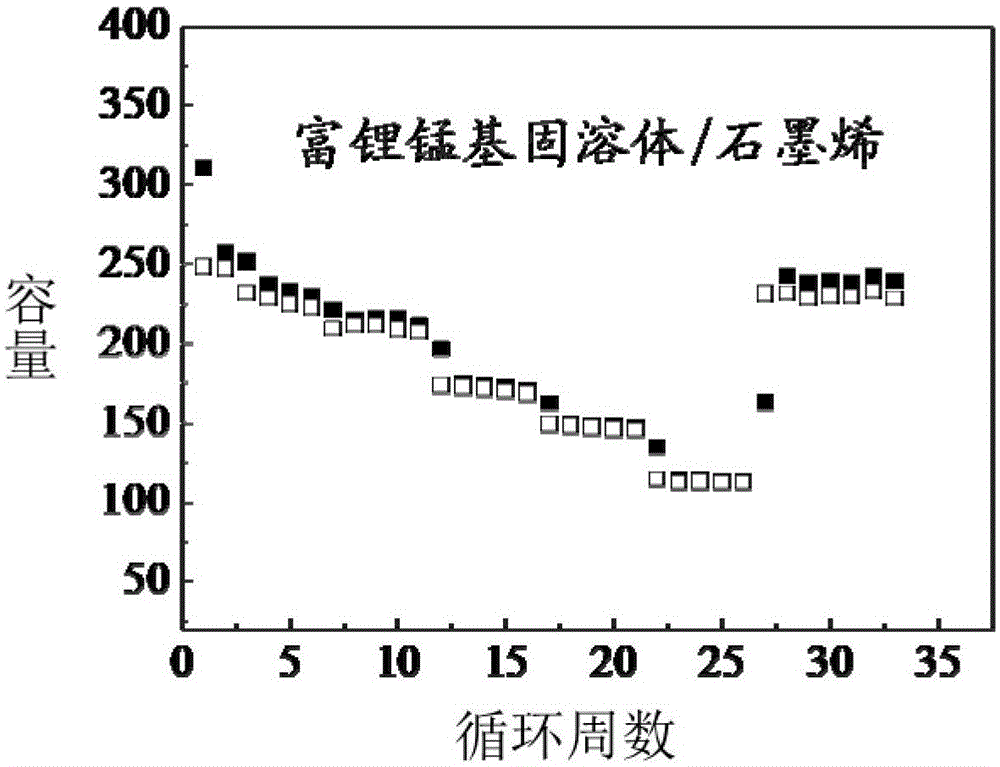

Image

Examples

Embodiment 1

[0072] Example 1 Using nitrate as a raw material, a lithium-rich manganese-based solid solution / graphene composite was prepared by co-precipitation

[0073] (1) Prepare Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 mixed solution, the total concentration of transition metal ions is 0.8mol L -1 . Use 1.5mol L -1 NaOH solution as precipitant, 0.3mol L -1 Ammonia solution is used as a complexing agent, and a certain amount of graphene oxide is added at the bottom of the CSTR reaction vessel, wherein the total amount of raw materials (Ni(NO 3 ) 2 ·6H 2 O, Co(NO 3 ) 2 ·6H 2 O and Mn(NO 3 ) 2 ) and graphene oxide weight ratio are 10:0.5;

[0074] (2) Under the protection of an inert gas, the three solutions are co-currently added to the reactor containing the graphene bottom liquid through a peristaltic pump. During the reaction, the pH is controlled to be 11, the stirring speed is 1000rpm, the reaction temperature is 60°C, and the reaction time is 12h....

Embodiment 2

[0080] Example 2 Using sulfate as a raw material, a lithium-rich manganese-based solid solution / graphene composite was prepared by co-precipitation

[0081] (1) Prepare NiSO according to the required molar ratio (0.58:0.11:0.11) 4 ·6H 2 O﹑CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O mixed solution, the total concentration of transition metal ions is 1.0mol L -1 . Use 2.0mol·L -1 NaOH solution as precipitant, 0.5mol L -1 Ammonia solution is used as a complexing agent, and a certain amount of graphene oxide is added at the bottom of the CSTR reaction vessel, wherein the raw material (NiSO 4 ·6H 2 O﹑CoSO 4 ·7H 2 O and MnSO 4 ·H 2 O) and graphene oxide weight ratio are 10:0.5;

[0082] (2) Under the protection of an inert gas, the three solutions are co-currently added to the reactor containing the graphene bottom liquid through a peristaltic pump. During the reaction, the pH is controlled to be 11, the stirring speed is 1000rpm, the reaction temperature is 50°C, and the reactio...

Embodiment 3

[0086] Example 3 Using acetate as a raw material and methanol as an organic solvent, a lithium-rich manganese-based solid solution / graphene composite material was prepared by a solvothermal method.

[0087] (1) The molar ratio (0.58:0.11:0.11) of CH 3 COOLi, (CH 3 COO) 2 Co, (CH 3 COO) 2 Mn, (CH 3 COO) 2 Ni and graphene oxide (the total amount of raw materials (CH 3 COOLi, (CH 3 COO) 2 Co, (CH 3 COO) 2 Mn and (CH 3 COO) 2 The weight ratio of Ni) to graphene oxide is 10:0.5) dissolved or dispersed (for graphene oxide) in methanol, fully stirred to form a mixed dispersion;

[0088] (2) Prepare 1.0mol·L -1 The oxalic acid solution is slowly added in the mixed solution formed in the previous step by a certain molar ratio (the mol ratio of Co and Ni ion total amount to oxalic acid is 1.3:1);

[0089] (3) At room temperature, stir magnetically for 2 hours to make it pre-react;

[0090] (4) All the solutions were transferred to the reactor and reacted at 200°C for 10 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com